Multi-band resonant frequency tracking circuit and method applied to ultrasonic machining

A resonant frequency and tracking circuit technology, applied in frequency measurement devices and other directions, can solve the problems of speeding up the resonant frequency tracking speed, poor flexibility, inability to distinguish whether the resonant frequency is the forward resonant frequency or the reverse resonant frequency, etc., to achieve a simple and fast implementation process. , Improve the effect of fast and accurate tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

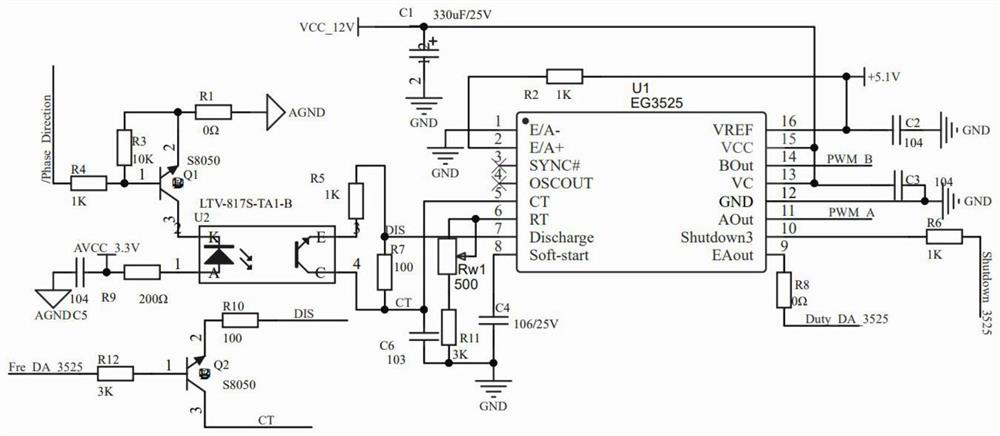

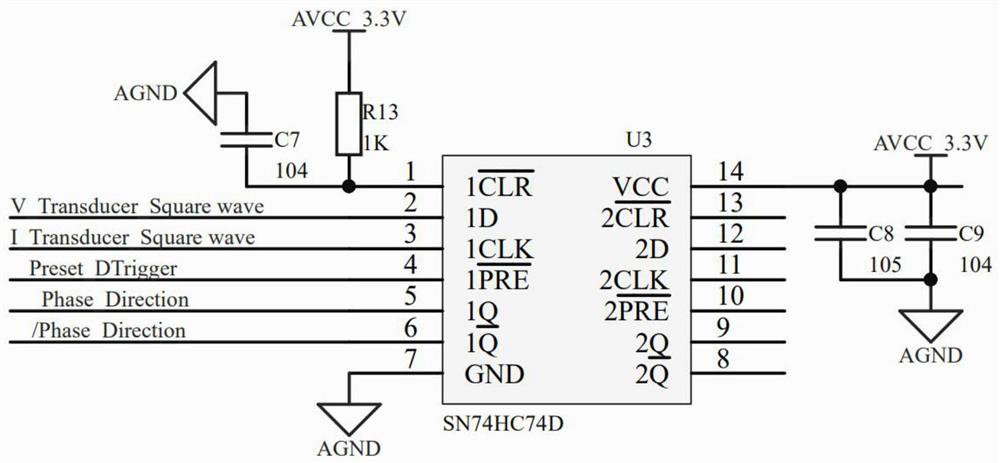

[0036] This embodiment provides a multi-band resonant frequency tracking circuit applied to ultrasonic processing, such as figure 1 As shown, it includes an output current voltage phase difference direction detection circuit and a multi-band resonance frequency tracking circuit, the detection signal output end of the output current voltage phase difference direction detection circuit is connected to the signal input end of the multi-band resonance frequency tracking circuit,

[0037] The signal input end of the multi-band resonance frequency tracking circuit includes a PWM control chip U1, a resistor R1, a resistor R2, a resistor R3, a resistor R4, a resistor R5, a resistor R6, a resistor R8, a resistor R9, a resistor R10, a resistor R11, and a resistor R12 , transistor Q1, transistor Q2, sliding rheostat Rw1, optocoupler U2, capacitor C1, capacitor C2, capacitor C3, capacitor C4, capacitor C5, capacitor C6,

[0038] One end of the resistor R4 is connected to the detection sig...

Embodiment 2

[0050] This embodiment discloses a multi-band resonant frequency tracking method applied to ultrasonic processing, such as image 3 As shown, including the following cycle steps:

[0051] S1. Start the equipment, and the piezoelectric transducer works at normal frequency;

[0052] S2. Real-time detection of the voltage and current signals of the piezoelectric transducer circuit through the output current and voltage phase difference direction detection circuit;

[0053] S3. According to the detection result, the multi-band resonant frequency tracking circuit drives the piezoelectric transducer to adjust the frequency.

[0054] In the above technical scheme, it is assumed that t 1 The ultrasonic power supply works normally at the driving signal frequency f at all times, and the frequency tracking is good, while at t 2 At this time, the piezoelectric transducer begins to be affected by the outside world, and its characteristics change.

[0055] t 2 moment, when the system i...

Embodiment 3

[0065] The difference between this embodiment and Embodiment 2 is that in S2, a system detuning duration threshold is preset, and the maximum value of the time threshold is set to 20 ms.

[0066] In the above technical solution, the maximum range of the time threshold is set to 20ms. Because there is enough time to monitor the level signal, the judgment result of the system detuning state is more accurate, the error rate of detuning judgment is greatly reduced, and then the adjustment is made quickly, and then it turns into an overall stable state in a small vibration state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com