A Local Resonance Type Building Vibration Isolation Foundation

A local resonance and architectural technology, applied in the direction of architecture, building types, building components, etc., can solve the problem of difficulty in micron-level small-amplitude vibration control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

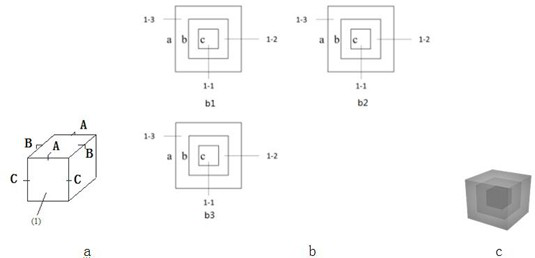

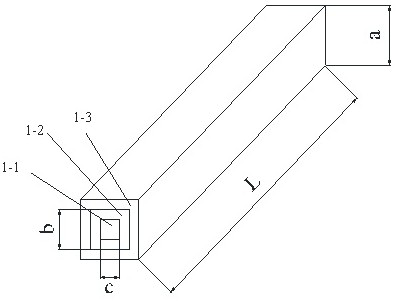

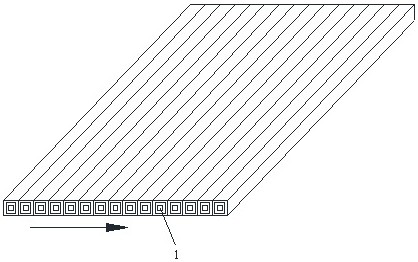

[0045] A local resonance type building vibration isolation foundation, the local resonance type building vibration isolation foundation is a topological structure composed of local resonance wave resistance units 1 through adjacent topologies, and the local resonance type wave resistance units 1 It is a block unit with three orthogonal directions close in size or a beam unit with two directions close in size and a third direction much larger than the other two directions. The topological structure is the local resonance type wave resistance unit 1 Topology along three dimensions: unidirectional, planar, or spatial. The local resonance type building vibration isolation foundation not only has bearing capacity, but also has the effect of isolating 6 Hz ultra-low frequency micro-vibration, and can cover the main mode frequency of the building structure.

[0046] The local resonance type wave resistance unit 1 is sequentially composed of a rigid core 1-1, an elastic wrapping layer...

Embodiment 2

[0055] This embodiment is a specific implementation of Embodiment 1, a local resonance type building vibration isolation foundation, which is composed of a prefabricated local resonance type wave resistance unit 1 through topology design, and the local resonance type wave resistance unit 1 can be designed as a cube ( figure 1 , that is block unit) or cuboid ( figure 2 , that is, the beam element). The local resonance type wave resistance unit 1 is sequentially composed of a rigid core 1-1, an elastic wrapping layer 1-2, and a bearing outer frame 1-3 from the inside to the outside, and the rigid core 1-1 is made of cast iron. Material parameters: elastic modulus 210000MPa, density 7800kg / m 3 , Poisson's ratio 0.275; the elastic wrapping layer 1-2 adopts rubber material, material parameters: modulus of elasticity 0.137MPa, density 1300kg / m 3 , Poisson's ratio 0.463; the bearing capacity outer frame 1-3 is made of concrete material, material parameters: elastic modulus 30000M...

Embodiment 3

[0058] This embodiment adopts the prefabricated beam unit of Embodiment 2, and the vibration isolation foundation of the local resonance type building is carried out by the local resonance type wave resistance unit 1 along the horizontal direction and the vertical direction of vibration propagation to perform periodic topology in the plane direction, such as Figure 7-Figure 8 As shown, it is placed under the building. Specifically, the number of topological periods and the value of the L dimension in the local resonance type wave resistance unit 1 depend on the size of the building. If necessary, the vibration isolation foundation of the local resonance type building needs to be extended beyond the building facade by no less than 0.5m . According to the above structure, it can be formed Figure 9 The forbidden band distribution. Depend on Figure 9 It can be seen that under the action of the local resonance type building vibration isolation foundation in this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com