Solid polycarboxylate superplasticizer prepared by using supercritical CO2 as solvent as well as preparation method and application of solid polycarboxylate superplasticizer

A technology of polycarboxylate and water reducer, which is applied in the field of solid polycarboxylate water reducer and its preparation, can solve the problems of complex production process, use of organic solvents, high viscosity of materials, etc., achieve high reactivity, improve dispersion performance, The effect of uniform heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

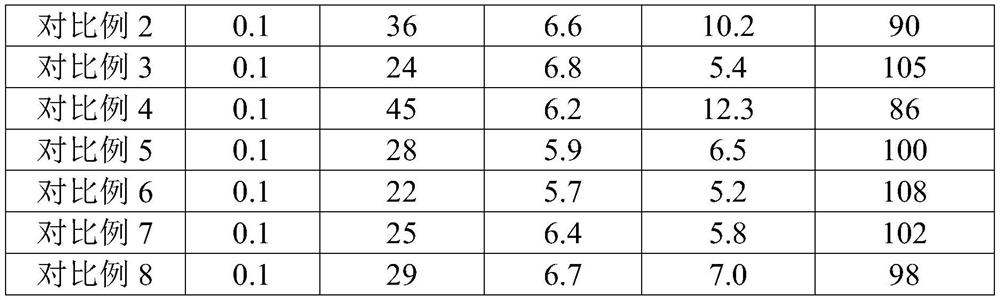

Examples

Embodiment 1

[0053] This embodiment provides a method using supercritical CO 2 The method for preparing solid polycarboxylate water reducer for solvent comprises the following steps:

[0054] 1) Introduce CO into the reactor of supercritical fluid 2 Gas, control the pressure in the reactor to 10MPa to make it into supercritical CO 2 ;

[0055] 2) Add 100g of isopentenol polyoxyethylene ether macromonomer into the premelt kettle, heat and melt it into a liquid state, transfer the liquid polyether macromonomer to the reactor of supercritical fluid through a pressure pump, and then transfer it to the reactor of supercritical fluid Add 0.2g of ammonium persulfate, 13g of acrylic acid, and 0.5g of mercaptoethanol; heat up to 35°C while mechanically stirring, and keep CO 2 The fluid volume is 100mL, the control speed is 100rpm, and then keep warm for 2h;

[0056] 3) After the reaction is completed, open the pressure relief valve, drop 1g of neutralizing agent sodium hydroxide (solid) into th...

Embodiment 2

[0058] This embodiment provides a method using supercritical CO 2 The method for preparing solid polycarboxylate water reducer for solvent comprises the following steps:

[0059] 1) Introduce CO into the reactor of supercritical fluid 2 Gas, control the pressure in the reactor to 12MPa to make it into supercritical CO 2 ;

[0060] 2) Add 120g of methallyl polyoxyethylene ether macromonomer into the pre-melting kettle, after heating and melting into a liquid state, the liquid polyether macromonomer is transferred to the reaction kettle of supercritical fluid by a pressure pump, and then Add 0.36g dicyclohexyl peroxydicarbonate, 18g methacrylic acid, 0.72g mercaptoacetic acid; heat up to 40°C while stirring mechanically, keep CO 2 The fluid volume is 140mL, the speed is controlled at 150rpm, and then the reaction is kept for 3h;

[0061] 3) After the reaction is completed, open the pressure relief valve, drop into 1.2g neutralizing agent potassium hydroxide (solid) in the re...

Embodiment 3

[0063] This embodiment provides a method using supercritical CO 2 The method for preparing solid polycarboxylate water reducer for solvent comprises the following steps:

[0064] 1) Introduce CO into the reactor of supercritical fluid 2 Gas, control the pressure in the reactor to 15MPa, make it into supercritical CO 2 ;

[0065] 2) Add 150g of vinyl glycol ether-based polyoxyethylene ether macromonomer into the pre-melting kettle, heat and melt it into a liquid state, and transfer the liquid polyether macromonomer to the supercritical fluid reaction kettle through a pressure pump , and then add 0.6g of azobisisobutyronitrile, 27g of acrylamide, 1.0g of mercaptopropionic acid; while stirring mechanically, the temperature is raised to 45°C, and the CO 2 The fluid volume is 300mL, the speed is controlled at 200rpm, and then the reaction is kept for 4h;

[0066] 3) After the reaction is completed, open the pressure relief valve, drop into 2.25g neutralizing agent sodium hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water reduction rate | aaaaa | aaaaa |

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com