Sewage/wastewater root deodorization treatment process and device

A technology for treatment device and wastewater, applied in water/sludge/sewage treatment, biological treatment device, biological water/sewage treatment, etc., can solve the problems of producing sulfur-like odor, affecting staff and substances, and achieving simple installation , The effect of improving processing efficiency, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

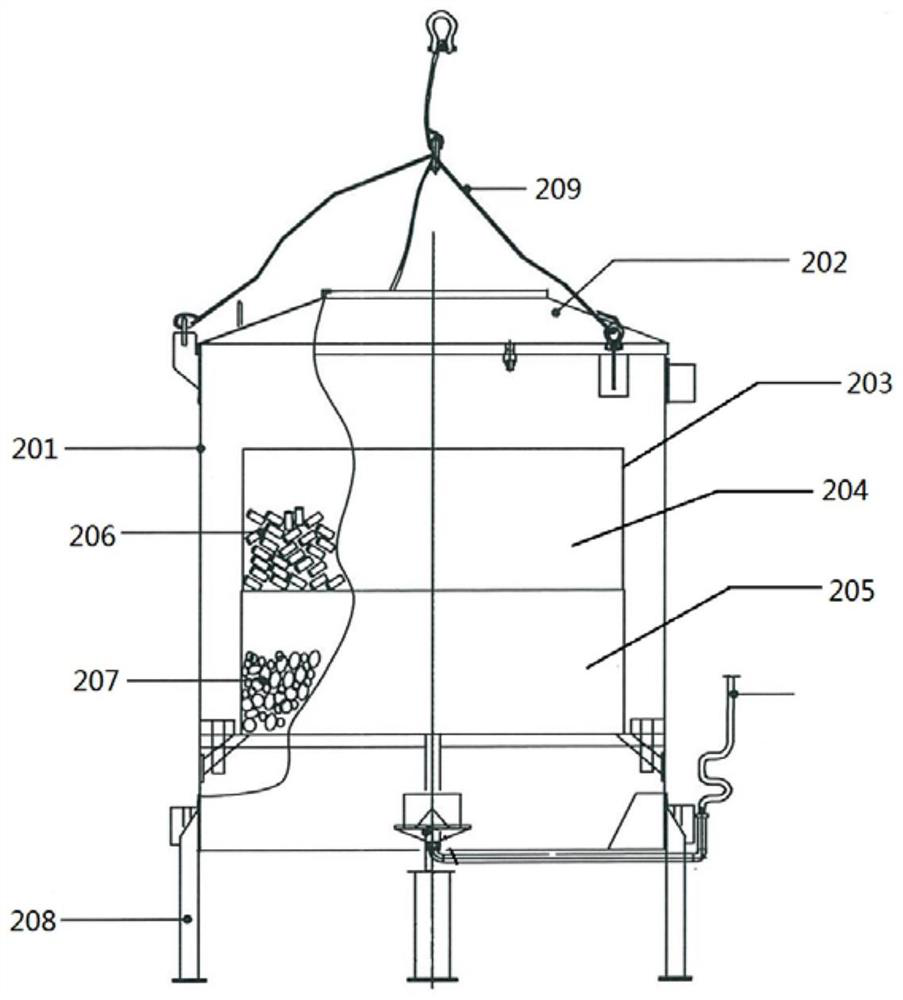

[0078] Mix and grind 67% of mineral raw materials to about 100 mesh, add 7% of surfactant F550, 15% of hydrophilic and affinity substances and water and continue stirring. The mass volume ratio of water and mineral raw materials is 1kg:0.2L, Then add 18% portland cement and continue to stir; wherein, the mineral raw materials include humus, peat, pozzolan, zeolite, alunite, kaolin, Limonite; the hydrophilic and affinity substances include diatomaceous earth, starch, limestone and calcium carbonate with a mass ratio of 5:2:3:5;

[0079] After the materials are mixed evenly, they are extruded and granulated by a cylindrical granulator. The particle size is set to Ф25mm, and the length is 55mm. Cut into strips and granulate. Put the cut filler on the shelf to dry and solidify at room temperature to obtain microbial composite Filler, the particle size of the microbial composite filler is Ф25mm, the length is about 55mm, and the volume is about 27cm 3 , with an average weight of 2...

Embodiment 2

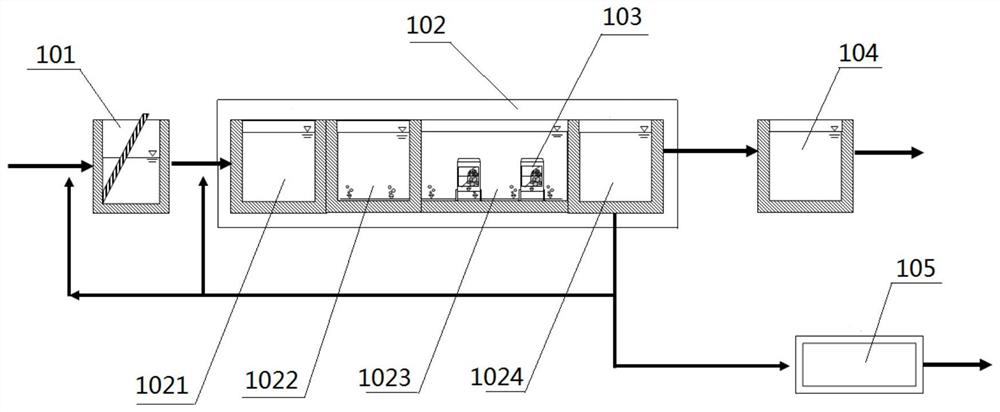

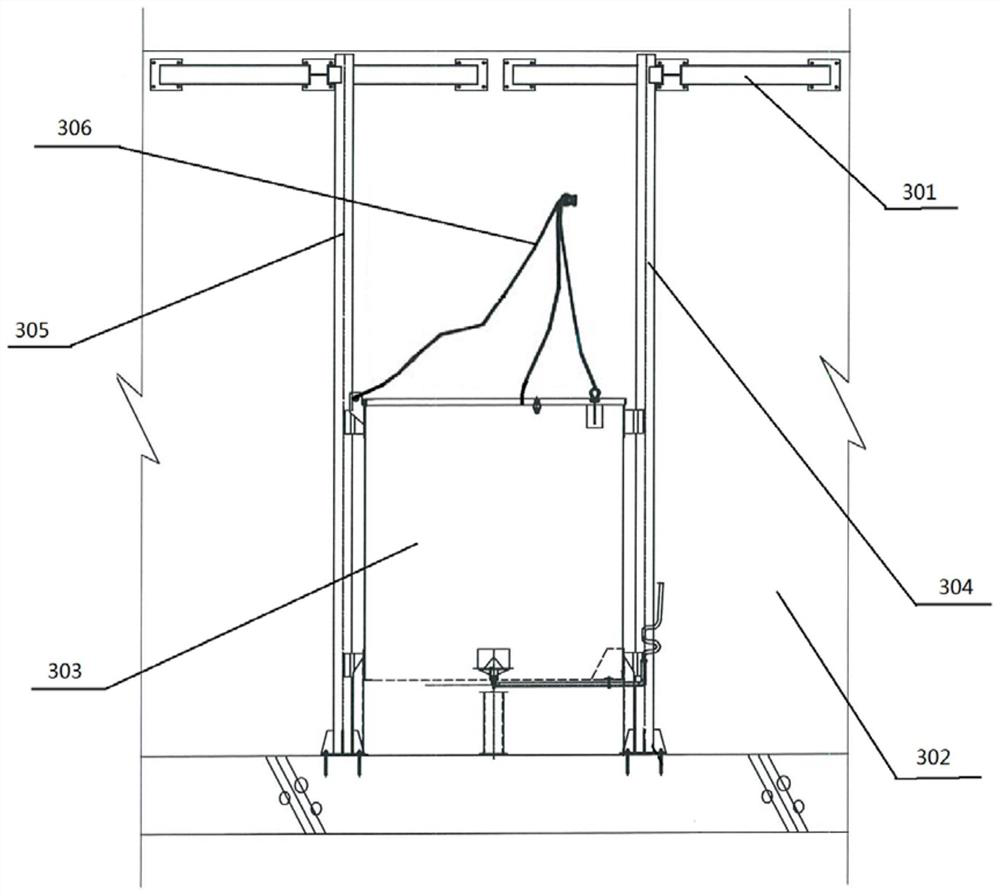

[0082] This embodiment is applied to Shanxi Yuncheng City West Sewage Treatment Plant, see figure 1 , figure 1 Schematic diagram of the structure of the sewage / waste water source deodorization treatment device provided for the embodiment of the present invention, the sewage treatment system of the treatment plant includes: a pretreatment device 101, the pretreatment device 101 includes a coarse grid and a fine grid for Pretreatment of sewage;

[0083] The water inlet is connected to the MSBR biological reaction tank 102 of the water outlet of the pretreatment device 101;

[0084] The sludge inlet is connected to the belt filter press 105 of the sludge outlet of the MSBR biological reaction tank 102;

[0085] The disinfection tank 104 whose water inlet is connected to the water outlet of the MSBR biological reaction tank 102;

[0086] The sludge outlet of the MSBR biological reaction tank 102 is respectively connected with the pretreatment device 101 and the water inlet of t...

Embodiment 3

[0096] This embodiment is applied to Kunming Puzhao Water Purification Plant. The sewage treatment system of this treatment plant includes: a pretreatment device, which includes a coarse grid and a fine grid, for pretreating the sewage;

[0097] The MSBR biological reaction tank that the water inlet is connected to the water outlet of the pretreatment device;

[0098] The sludge inlet is connected to the centrifugal dehydrator of the sludge outlet of the MSBR bioreactor;

[0099] The ultraviolet sterilizing pool that water inlet is connected with the water outlet of described MSBR bioreactor;

[0100] The sludge outlet of the MSBR biological reaction tank is respectively connected with the pretreatment device and the water inlet of the MSBR biological reaction tank, and the return flow of sludge to the pretreatment device is 5-10%.

[0101] Wherein, the MSBR biological reaction tank includes anaerobic zone, anoxic zone, aerobic zone and SBR zone which are arranged in sequence...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com