A photoreactor for wastewater treatment

A kind of photoreactor, technology of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Choose a glass mirror with a size of 100×30cm and a hollow glass bead with a diameter of 2.5cm and a through hole of 2mm in diameter, wash and dry with acetone, ethanol, and deionized water in turn; brush the surface of the dried glass mirror with a certain concentration Hydrofluoric acid buffer solution, the glass beads are immersed in the hydrofluoric acid buffer solution, and the etching process is carried out. The etching time is 3 hours; after the etching is completed, the glass mirror and glass beads are repeatedly washed with deionized water to PH= 7. Air dry naturally and set aside.

[0028] Coat a layer of titanium dioxide transparent sol precursor on the treated glass mirror surface, place it vertically until it is naturally dried, repeat the above-mentioned coating operation 5 times, dry it at 80°C and put it in a calcining kiln to slowly raise the temperature to 500 Calcined at ℃ for 2h, keep it for later use after natural cooling.

[0029] Soak the processed gl...

Embodiment 2

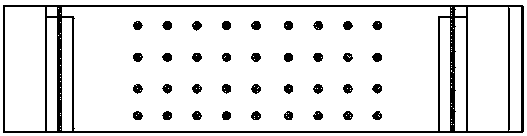

[0033] The arrangement of the glass beads in the photoreactor in Example 1 was changed to be flat on the bottom of the reactor, the packing density was 4 per 10cm, and the packing height was 2 layers. The specific arrangement is as Figure 4 Shown.

Embodiment 3

[0035] The arrangement of the glass beads in the photoreactor in Example 1 was changed to use a wooden stick with a diameter of 1mm to string the glass beads into strings, the glass beads were separated by 1cm; the glass beads were fixed by pasting on the glass mirror surface, and the beads Arranged in a triangle, spaced 1cm apart. The specific arrangement is as Figure 5 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com