Lithium-type low-silica-alumina-ratio molecular sieve, preparation method and application of molecular sieve as adsorbent

A low-silicon-aluminum ratio, molecular sieve technology, applied in the direction of molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of high price, achieve high mechanical strength, uniform shape and size, The effect of increased mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

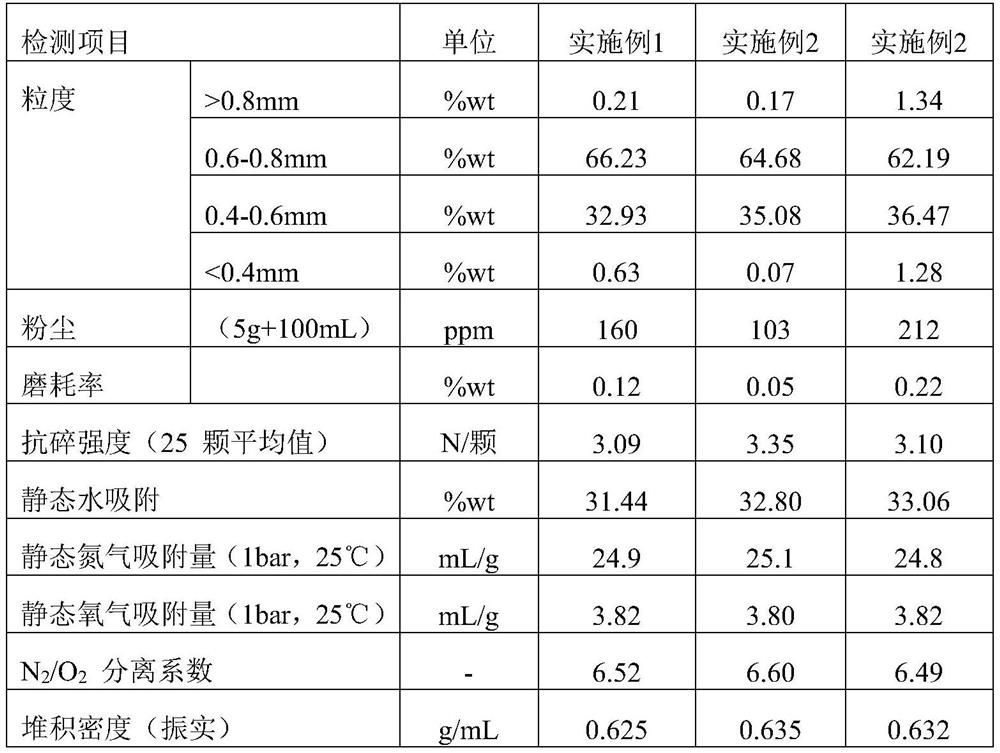

Examples

Embodiment 1

[0017] 1) Preparation of alkaline solution a: Weigh KOH and NaOH solids with a mass ratio of 1:1, add distilled water, mix and stir until clear, and configure an aqueous solution with a mass fraction of 15% (the sum of KOH and NaOH) to obtain an alkaline solution a;

[0018] 2) Preparation of gel b: adding an aqueous aluminum hydroxide solution with a mass fraction of 15% to an aqueous sodium hydroxide solution with a mass fraction of 30%, stirring at 80°C until clear, and configuring a sodium metaaluminate solution as an aluminum source; Water glass is added to distilled water, stirred evenly at 30°C to prepare a silica-alumina gel with a mass fraction of 12% as a silicon source; under stirring conditions, add the alkaline solution a prepared in step 1) to the sodium metaaluminate solution, and wait to dissolve Then add silica-alumina gel under stirring, mix the two thoroughly, and age at 30°C for 16 hours to obtain gel b; the aluminum source is Al 2 o 3 In terms of silicon...

Embodiment 2

[0023] 1) Preparation of alkaline solution a: Weigh KOH and NaOH solids with a mass ratio of 1:1, add distilled water, mix and stir until clear, and configure an aqueous solution with a mass fraction of 15% (the sum of KOH and NaOH) to obtain an alkaline solution a;

[0024]2) Preparation of gel b: adding an aqueous solution of aluminum hydroxide with a mass fraction of 15% to an aqueous solution of sodium hydroxide with a mass ratio of 30%, stirring at 80° C. until clarification, and preparing a sodium metaaluminate solution as an aluminum source. Add water glass into distilled water, stir evenly at 30°C to prepare a silica-alumina gel with a mass fraction of 12% as a silicon source; Glue (SiO 2 / Al 2 o 3 =6.50, NaK / Si=3.0, H 2 O / NaK=18), the two are fully mixed, and aged at 30°C for 16 hours to obtain gel b; the aluminum source is Al 2 o 3 In terms of silicon source as SiO 2 Calculated, the molar ratio of silicon source to aluminum source in gel b is 6.5:1, the molar ...

Embodiment 3

[0029] 1) Preparation of alkaline solution a: Weigh KOH and NaOH solids with a mass ratio of 1:1, add distilled water, mix and stir until clear, and configure an aqueous solution with a mass fraction of 15% (the sum of KOH and NaOH) to obtain an alkaline solution a;

[0030] 2) Preparation of gel b: adding an aqueous aluminum hydroxide solution with a mass fraction of 15% to an aqueous sodium hydroxide solution with a mass fraction of 30%, stirring at 80°C until clear, and configuring a sodium metaaluminate solution as an aluminum source; Water glass is added to distilled water, stirred evenly at 30°C to prepare a silica-alumina gel with a mass fraction of 12% as a silicon source; under stirring conditions, add the alkaline solution a prepared in step 1) to the sodium metaaluminate solution, and wait to dissolve Then add silica-alumina gel under stirring, mix the two thoroughly, and age at 30°C for 16 hours to obtain gel b; the aluminum source is Al 2 o 3 In terms of silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com