Taking-out and storing equipment for powder metallurgy finished products

A powder metallurgy and finished product technology, applied in the field of taking out and storing equipment, can solve the problems of high labor consumption and low work efficiency, and achieve the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

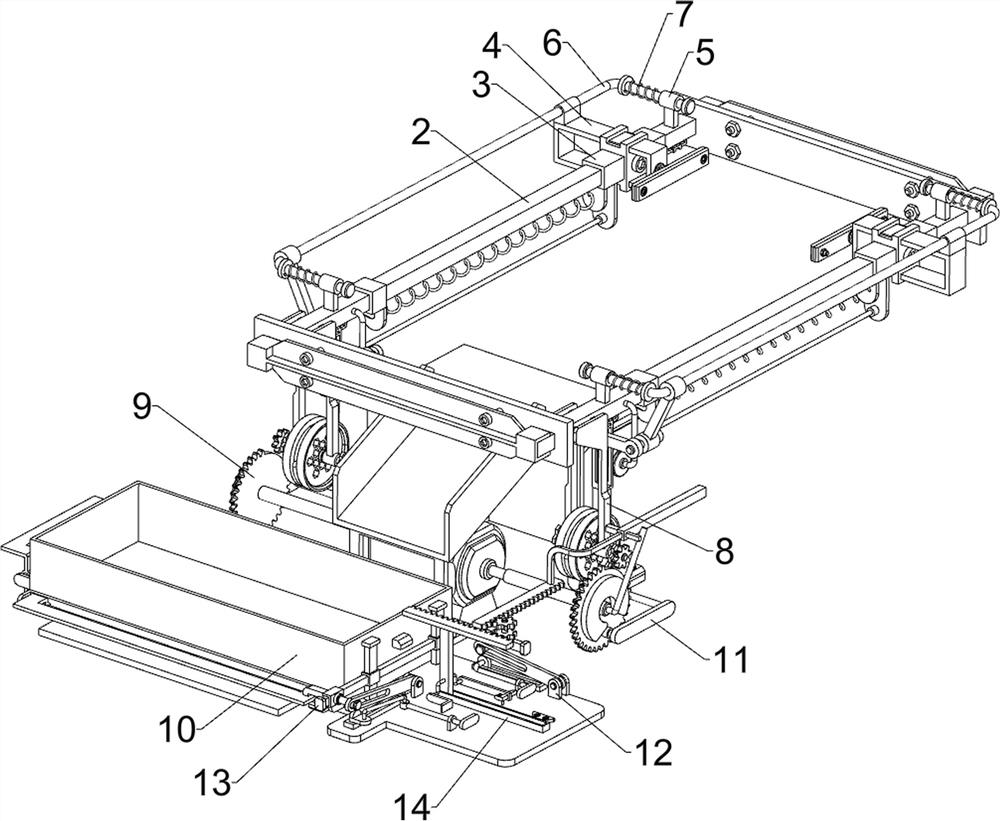

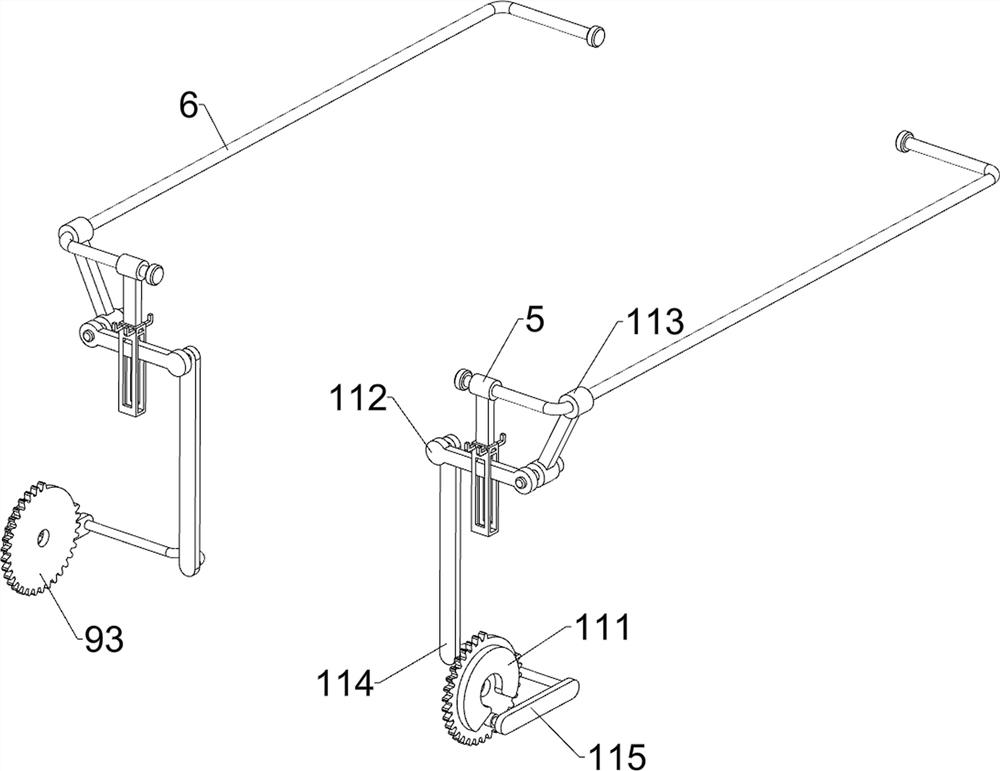

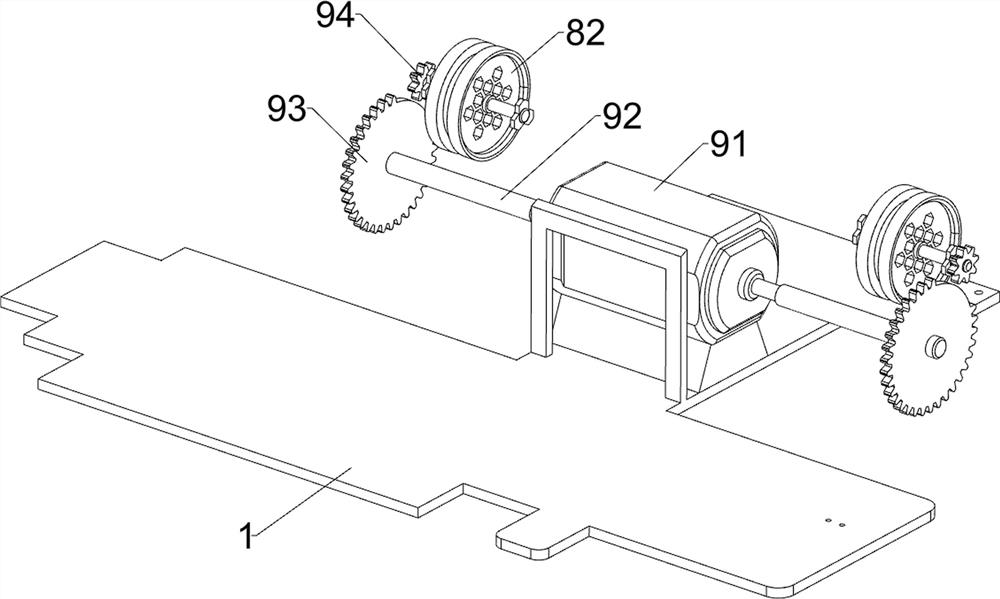

[0030] A take-out and storage equipment for powder metallurgy finished products, such as Figure 1-12 As shown, it includes a frame 1, a bar block 2, a sliding sleeve 3, a clamp 4, a first guide plate 5, a sliding rod 6, a first spring 7, a pulling assembly 8 and a driving assembly 9, and the upper part of the frame 1 is left-right symmetrical. A strip block 2 is provided, and a sliding sleeve 3 is provided on the strip block 2, and a clamp 4 is slidingly provided on the sliding sleeve 3. The front and rear parts of the strip block 2 are all provided with a first guide plate 5, and the front and rear A slide bar 6 is slidably arranged between the two first guide plates 5, and the slide bar 6 is slidably connected with the fixture 4, and a first spring 7 is wound between the slide bar 6 and the first guide plate 5, and the strips The block 2 is provided with a pulling assembly 8, and the lower part of the frame 1 is provided with a driving assembly 9.

[0031] When using this ...

Embodiment 2

[0037] On the basis of Example 1, such as figure 1 , figure 2 , Figure 5 , Figure 8 and Figure 9 As shown, a storage assembly 10 is also included. The storage assembly 10 includes a storage frame 101, a contact block 102, a support plate 103 and an inclined frame 104. The contact block 102 is provided with the same contact block 102 on the rear side of the storage frame 101 , the support plate 103 is provided at the front of the frame 1 , and the inclined frame 104 is provided at the top of the support plate 103 .

[0038] When using the device, the clamp 4 slides backwards to release the metallurgical finished product, and the metallurgical finished product falls into the inclined frame 104, and the metallurgical finished product in the inclined frame 104 slides down into the storage frame 101, so that it can be taken out Centralized collection and storage of metallurgical products.

[0039] On the basis of Example 1, such as figure 2 and Figure 6 As shown, it al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com