Method and device for preparing carbon-coated metal nanoparticles through electric arc in liquid nitrogen

A technology of metal nanoparticles and carbon coating, applied in the direction of nano-carbon, nanotechnology, nanotechnology, etc., can solve the problems of high requirements for preparation equipment, complicated operation, low yield, etc., to avoid continuous expansion, simple operation, and save Go to high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

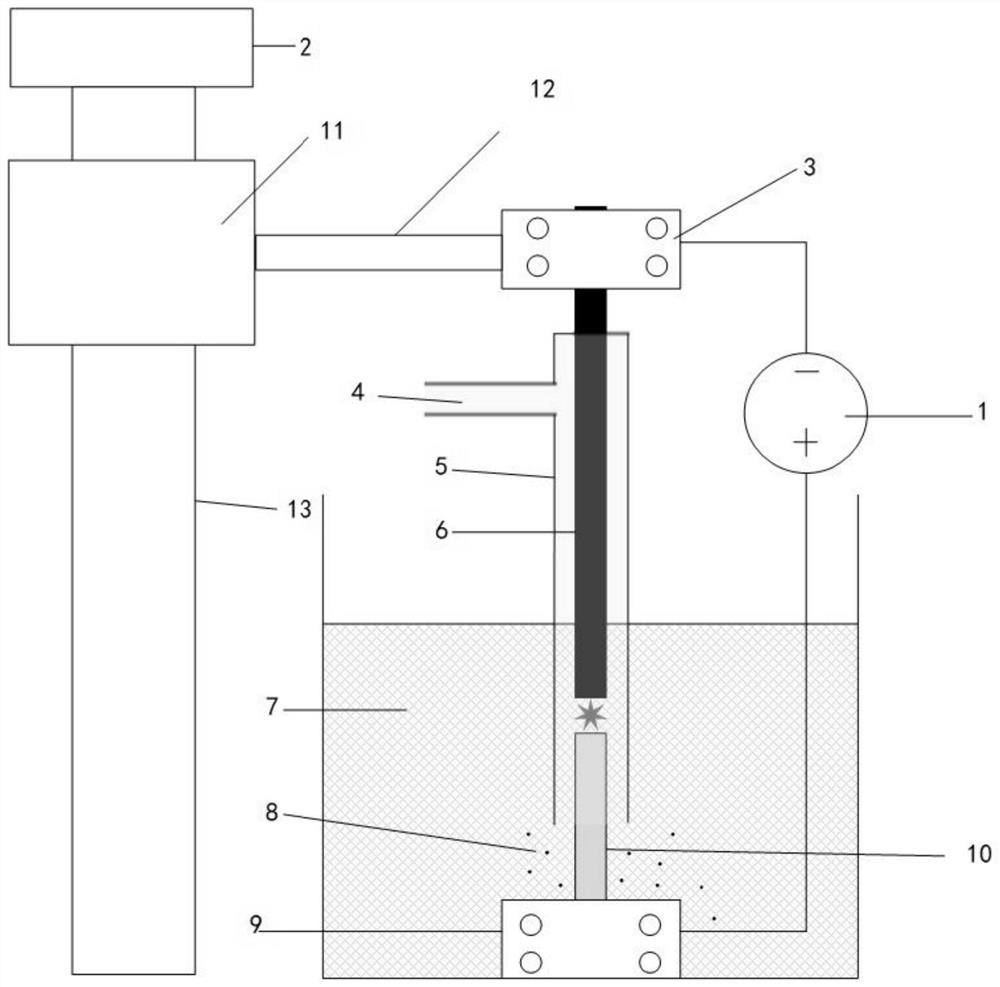

[0056] Step 1. Clean the graphite rod 6 and the metal rod 10 as raw materials, rinse with absolute ethanol to remove oil and impurities on the electrode surface, and then rinse the absolute ethanol with deionized water. The graphite rod 6 is a high-purity graphite rod with a diameter of 6mm and a purity of 99.9%. The metal rod 10 is an aluminum rod with a purity of 99.7% and a diameter of 12 mm. Before cleaning, the oxide layer on the surface of the aluminum rod is polished and removed with sandpaper.

[0057] Step 2: Clamp the aluminum rod on the lower conductive clip 9 as an anode; clamp the graphite rod 6 on the upper conductive clip 3 as a cathode.

[0058] Step 3, the gas introduced into the liquid nitrogen through the quartz tube 5 is argon; the cathode and anode and the quartz tube 5 are placed in a beaker filled with liquid nitrogen 7 to ensure that the contact position of the cathode and anode is below the liquid nitrogen surface .

[0059] Step 4: Set the current o...

Embodiment 2

[0063] Step 1. Clean the graphite rod 6 and the metal rod 10 as raw materials, rinse with absolute ethanol to remove oil and impurities on the electrode surface, and then rinse the absolute ethanol with deionized water. The graphite rod 6 is a high-purity graphite rod with a diameter of 6mm and a purity of 99.9%. The metal rod 10 is a copper rod with a purity of 99.7% and a diameter of 12 mm. Before cleaning, the oxide layer on the surface of the copper rod is polished and removed with sandpaper.

[0064] Step 2: Clamp the copper rod on the lower conductive clip 9 as an anode; clamp the graphite rod 6 on the upper conductive clip 3 as a cathode.

[0065] Step 3, the gas introduced into the liquid nitrogen 7 through the quartz tube 5 is helium; the cathode and anode and the quartz tube 5 are placed in a beaker filled with liquid nitrogen 7 to ensure that the contact position of the cathode and anode is at the liquid nitrogen level under.

[0066] Step 4: Set the current of th...

Embodiment 3

[0069] Step 1. Clean the graphite rod 6 and the metal rod 10 as raw materials, rinse with absolute ethanol to remove oil and impurities on the electrode surface, and then rinse the absolute ethanol with deionized water. The graphite rod 6 is a high-purity graphite rod with a diameter of 6mm and a purity of 99.9%. The metal rod 10 is an iron rod with a purity of 99.7% and a diameter of 12mm. Before cleaning, the surface of the iron rod is polished clean with sandpaper.

[0070] Step 2: Clamp the iron rod on the lower conductive clip 9 as an anode; clamp the graphite rod 6 on the upper conductive clip 3 as a cathode.

[0071] Step 3, the gas introduced into the liquid nitrogen 7 through the quartz tube 5 is carbon dioxide; the cathode and anode and the quartz tube 5 are placed in a beaker filled with liquid nitrogen 7 to ensure that the contact position of the cathode and anode is above the liquid nitrogen surface Down.

[0072] Step 4: Set the current of the DC power supply 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com