Polyimide coating modified polyolefin composite diaphragm and preparation method thereof

A technology of polyolefin membrane and polyimide coating, applied in coating, electrochemical generator, electrical components, etc., can solve the problems of little improvement in thermal dimensional stability and low temperature resistance of organic polymers, etc. To achieve the effect of improving thermal stability, good wettability and increasing integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

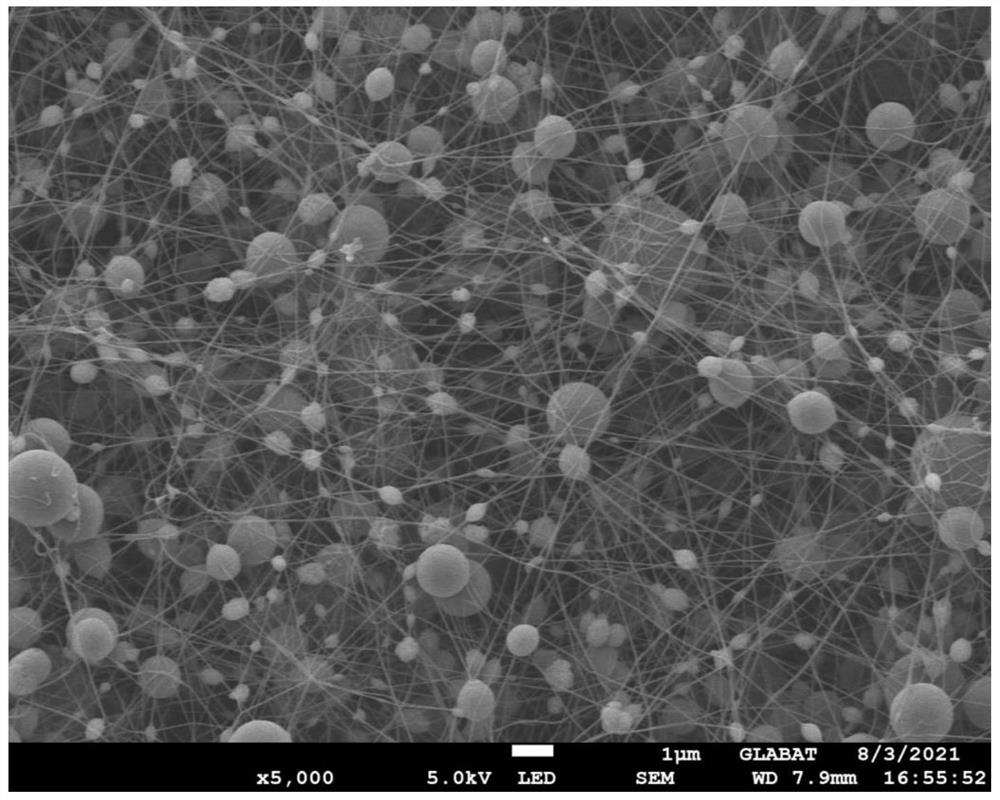

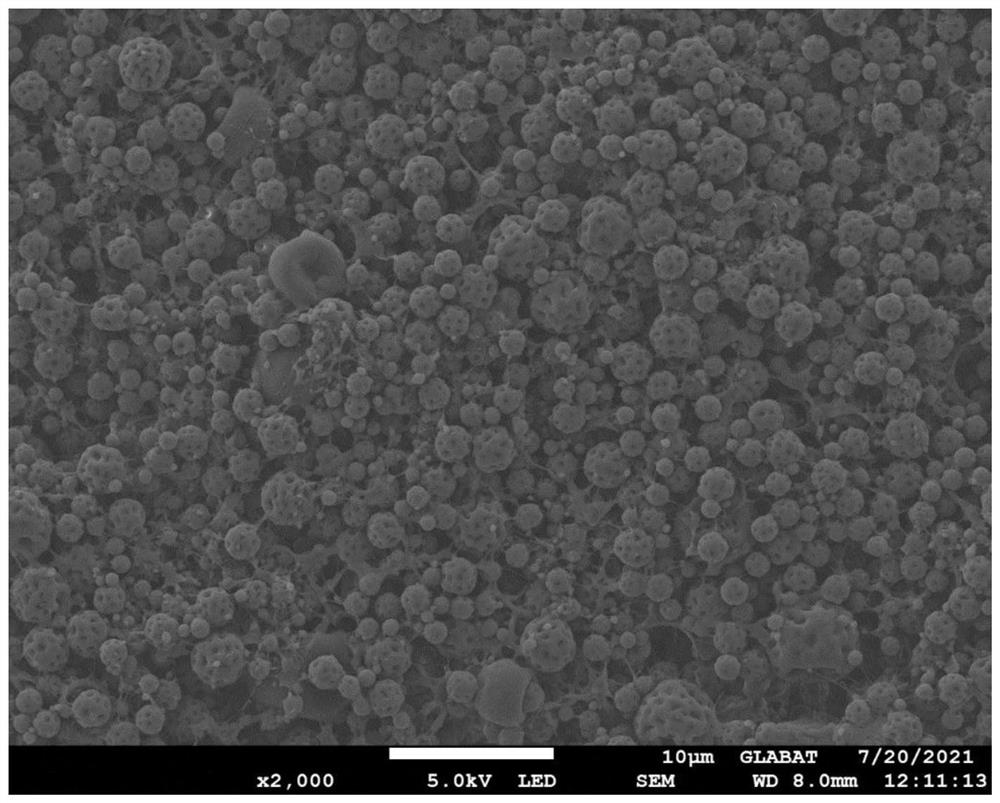

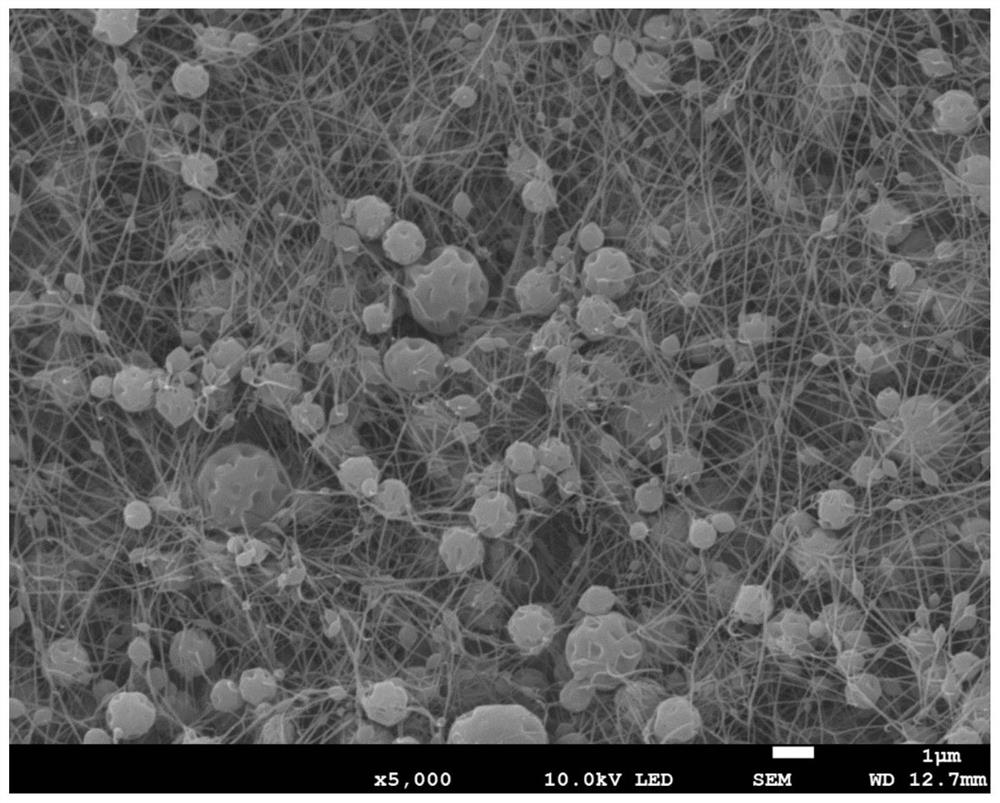

[0034] Preparation of PMDA / ODA system polyimide with fiber / microsphere composite morphology: monomer pyromellitic dianhydride (PMDA) and monomer 4,4'-diaminodiphenyl ether (ODA) in a molar ratio of 1 : 1 weighed, reacted in the solvent N, N-dimethylformamide (DMF) for 10 h under ice-water bath conditions at 0°C to obtain a clear and transparent polyamic acid solution with a mass concentration of 12%, and the electric field strength was 1kV / cm Electrospinning in an electric field, and the polyamic acid film is collected by a stainless steel drum, and then the polyamic acid film is peeled off from the roller, and placed in a high-temperature furnace for imidization treatment. The heating program is: 5°C / min The heating rate is raised from room temperature to 300°C, stay at 300°C for 1 hour, turn on the furnace, and cool down to room temperature naturally

[0035]Prepare the coating slurry: configure the coating slurry with the polymer binder, water and ethanol mixed solvent, and...

Embodiment 2

[0041] Preparation of PMDA / MDA system polyimide with fiber / microsphere composite morphology: Weigh monomer pyromellitic dianhydride (PMDA) and monomer diaminodiphenylmethane (MDA) in a molar ratio of 1:1, Reaction in the solvent N,N-dimethylformamide (DMF) for 10 hours under ice-water bath conditions at 0°C to obtain a clear and transparent polyamic acid solution with a mass concentration of 12%, and electrospinning in an electric field with an electric field strength of 1kV / cm The polyamic acid film is collected by a stainless steel drum, and then the polyamic acid film is peeled off from the roller and placed in a high-temperature furnace for imidization treatment. The heating program is: from room temperature to 5°C / min. Raise to 300°C, stay at 300°C for 1 hour, turn on the furnace, and cool down to room temperature naturally

[0042] Prepare the coating slurry: configure the coating slurry with the polymer binder, water and ethanol mixed solvent, and polyimide film accordi...

Embodiment 3

[0048] Preparation of polyimide with fiber / microsphere composite morphology PMDA / PDA system: Weigh monomer pyromellitic dianhydride (PMDA) and monomer p-phenylenediamine (PDA) in a molar ratio of 1:1, The solvent N,N-dimethylformamide (DMF) was reacted in an ice-water bath at 0°C for 10 hours to obtain a clear and transparent polyamic acid solution with a mass concentration of 12%, which was electrospun in an electric field with an electric field strength of 1kV / cm , collect the polyamic acid film through a stainless steel drum, then peel the polyamic acid film from the roller, and place it in a high-temperature furnace for imidization treatment. to 300°C, stay at 300°C for 1 hour, turn on the furnace, and cool down to room temperature naturally

[0049] Prepare the coating slurry: configure the coating slurry with the polymer binder, water and ethanol mixed solvent, and polyimide film according to the weight ratio of 1:79:20. Firstly, 0.8 g of polyimide film was weighed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com