Preparation method and device of acetamidine hydrochloride and use method of device

A technology of acetamidine hydrochloride and reaction is applied in the field of preparation of acetamidine hydrochloride, which can solve the problems of uneven reaction of raw materials, waste of raw materials and high production cost, and achieve the effects of improving uniformity, improving yield and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment one: the present embodiment provides a kind of preparation method of acetamidine hydrochloride, comprises the following steps:

[0050] 1) Sour methanol configuration: Methanol is put into the acid methanol configuration kettle, and cooled to below 10°C for use; hydrogen chloride is passed into the acid methanol configuration kettle through the Roots booster fan, and the temperature is kept below 20°C to absorb hydrogen chloride; The configuration is completed when the concentration reaches 45% and above;

[0051] 2) Ammonia-methanol configuration: Add methanol to the ammonia-methanol preparation kettle, turn on the chilled water to cool down to below 15°C, and start passing liquid ammonia, the liquid ammonia is controlled at a speed of about 300Kg / h, and the temperature of methanol in the kettle is lower than 15°C. When the amount of liquid ammonia entering is about 1500Kg, stop feeding liquid ammonia, and take a sample to measure the content after half an h...

Embodiment 2

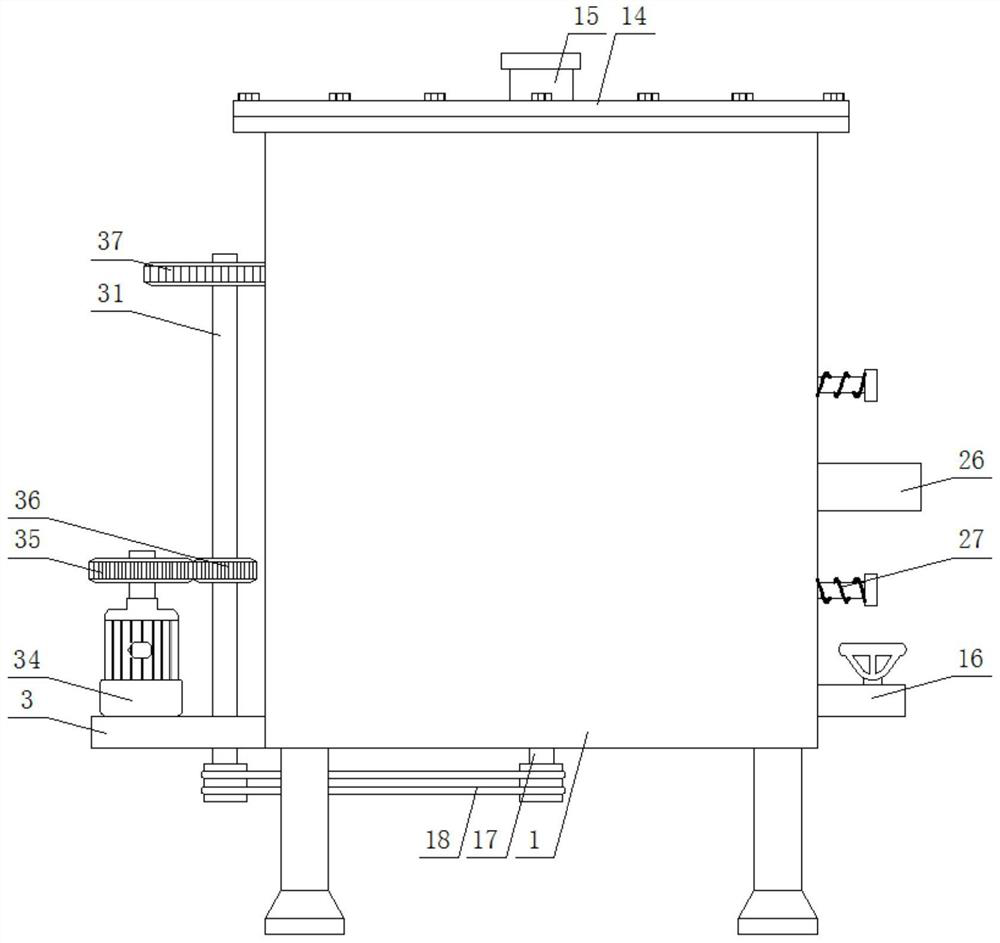

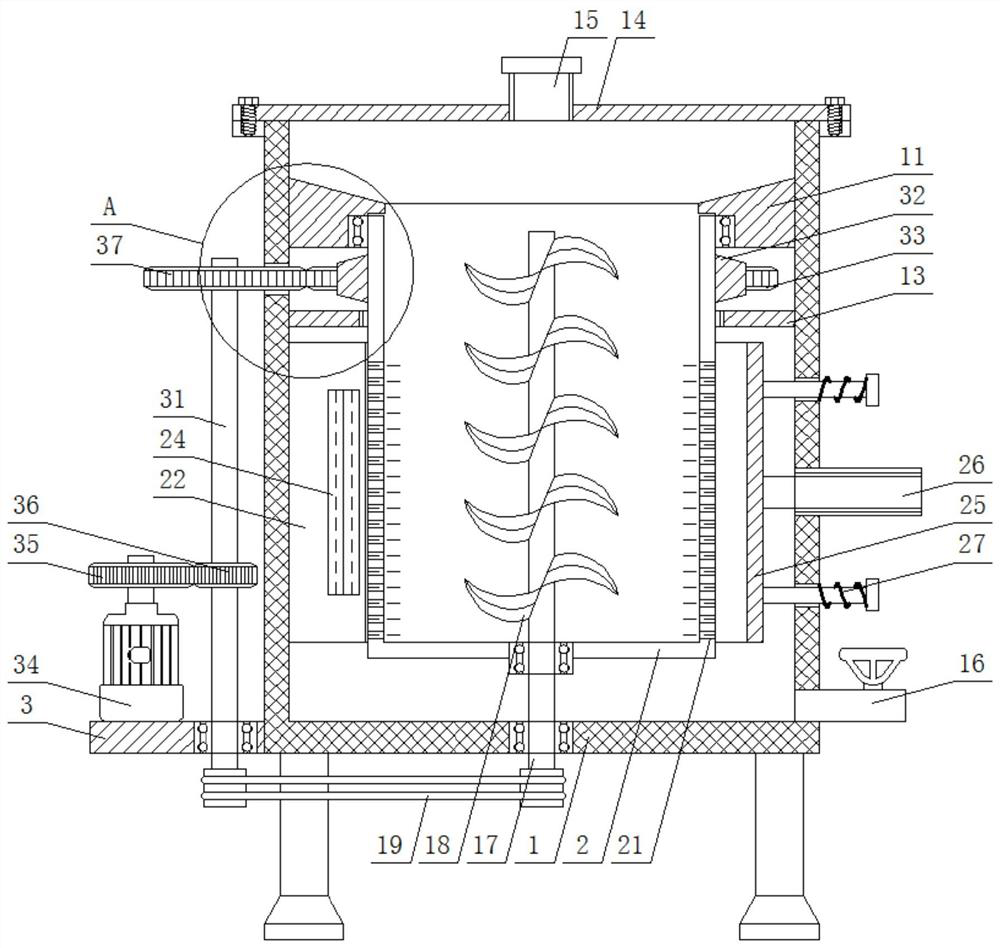

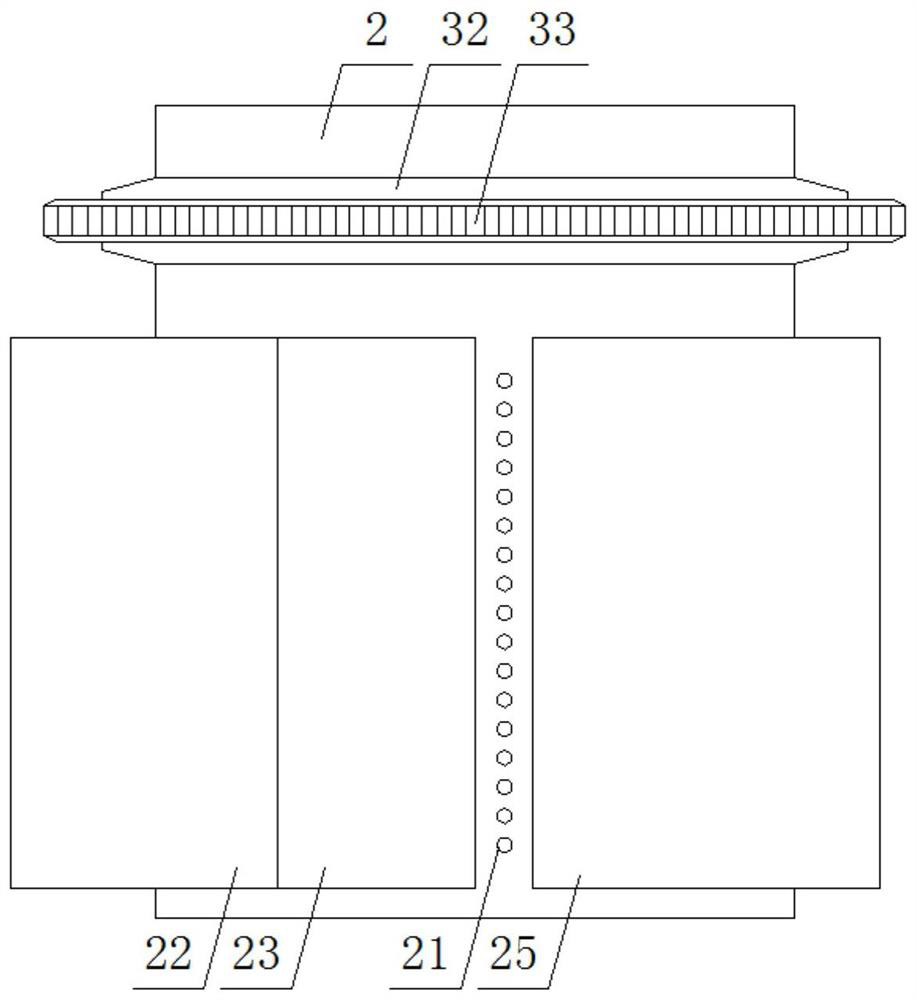

[0058] Embodiment two: This embodiment provides a kind of device for preparing acetamidine hydrochloride, see Figure 1-5 Specifically, it includes a bottom box 1, a control assembly, and an engagement mechanism, and is characterized in that: the bottom box 1 is a circular box with an open top surface, and the bottom box 1 is provided with a reaction inner cylinder 2 suspended in the air , the top of the reaction inner cylinder 2 is provided with a concentrically affixed conical ring 11 on the inner wall of the bottom box 1, and a concentrically affixed stop ring 13 is provided on the inner wall of the bottom box 1 under the conical ring 11 , the reaction inner cylinder 2 is rotatably connected with the inner wall of the stop ring 13;

[0059] A plurality of centrifugal holes 21 are evenly distributed on the outer surface of the reaction inner cylinder 2 under the limit ring 13, and a control assembly is arranged on the reaction inner cylinder 2 under the limit ring 13. One si...

Embodiment 3

[0068] Embodiment three: in embodiment one, when using above-mentioned device, comprise the following steps:

[0069] The first step is to start the motor 34, the motor shaft of the motor 34 drives the driving gear 35 to rotate synchronously, the meshing drives the driven gear 36 and the linkage shaft 37 to rotate in the opposite direction, and then drives the first pulley and the linkage gear 37 to rotate in the opposite direction, and the engagement drives the gears The ring 33, the trapezoidal ring 32 and the reaction inner cylinder 2 rotate positively along the limiting ring 13 and the bearing ring 12;

[0070] In the second step, the first pulley drives the second pulley and the stirring shaft 17 to rotate reversely along the fixed bearing through the drive belt 19, and then drives the stirring paddle 18 to reversely rotate in the reaction inner cylinder 2, thereby accelerating the reaction of the inner cylinder 2. the efficiency of the mixing reaction;

[0071] In the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com