Heat dissipation device

A heat dissipation device and heat pipe technology, applied in the direction of indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of limited effect, inability to dissipate high heat, poor heat dissipation efficiency, etc., to increase chaos and improve The effect of contact opportunity and improvement of heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The implementation of the present invention is described below through specific specific examples, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the content disclosed in this description, and can also be implemented through other different specific examples or apply.

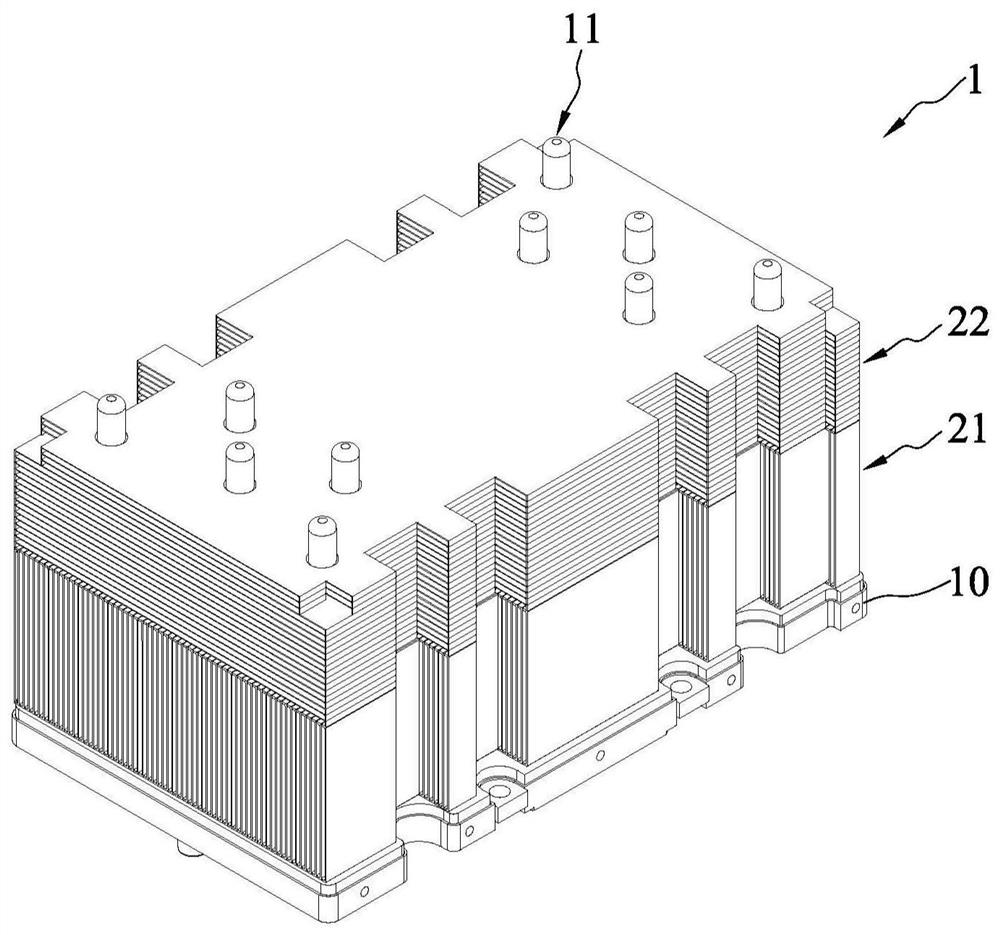

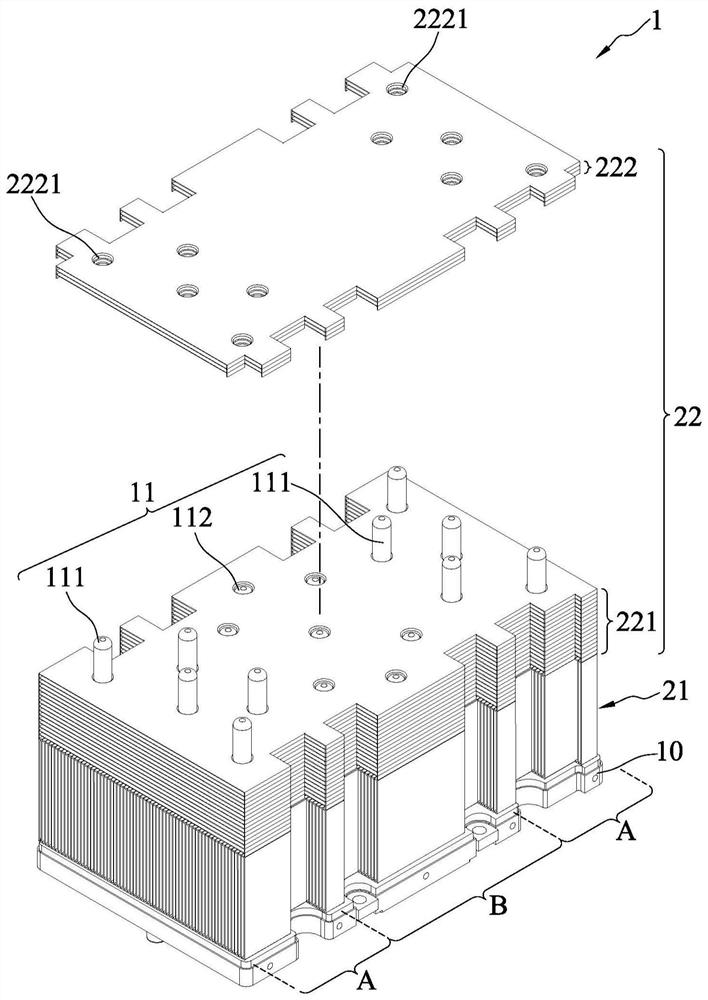

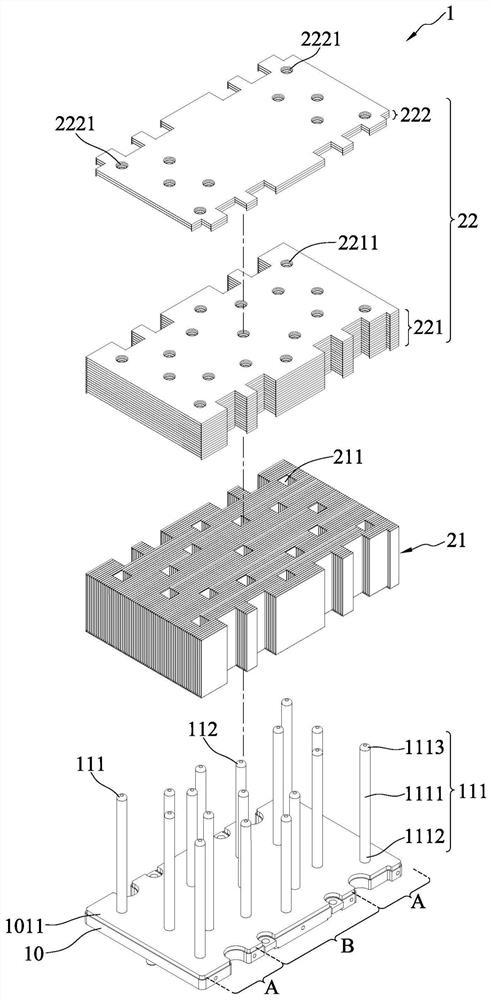

[0058] Please also see figure 1 , figure 2 and image 3 , The heat dissipation device 1 of the present invention includes a vapor chamber unit 10 , a heat pipe set 11 , a first fin set 21 and a second fin set 22 . The heat pipe group 11 is arranged on the outer surface 1011 of the chamber unit 10, the first fin group 21 is arranged on the outer surface 1011 of the chamber unit 10 and the heat pipe group 11 is sleeved, and the heat pipe group 11 is partially exposed, and the second The two fin sets 22 are stacked on the first fin set 21 and cover the exposed portion of the heat pipe set 11 by the first fin set 21 , and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com