Heating equipment for preparing sample

A technology for heating equipment and preparing samples, applied in the field of nuclear power, can solve the problems of affecting the service life of the instrument, taking a long time for evaporation and concentration, and increasing the humidity in the laboratory, so as to reduce steam spillage, improve efficiency and safety, and reduce humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

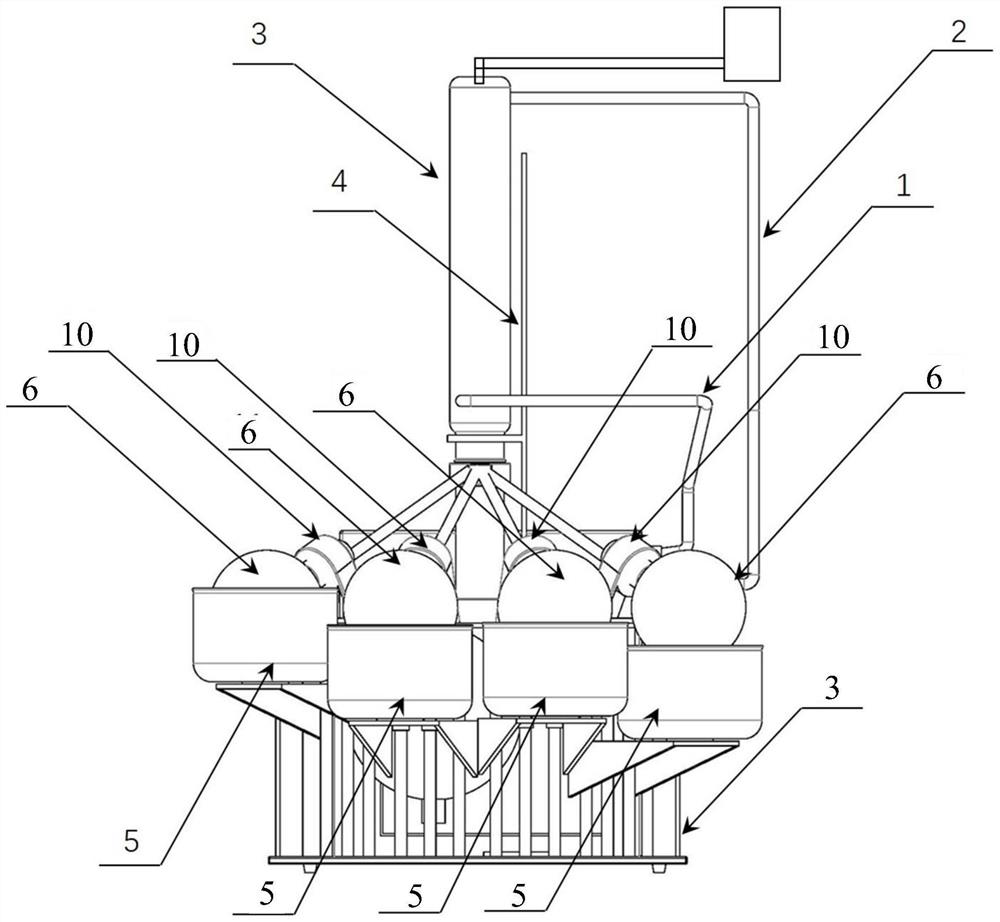

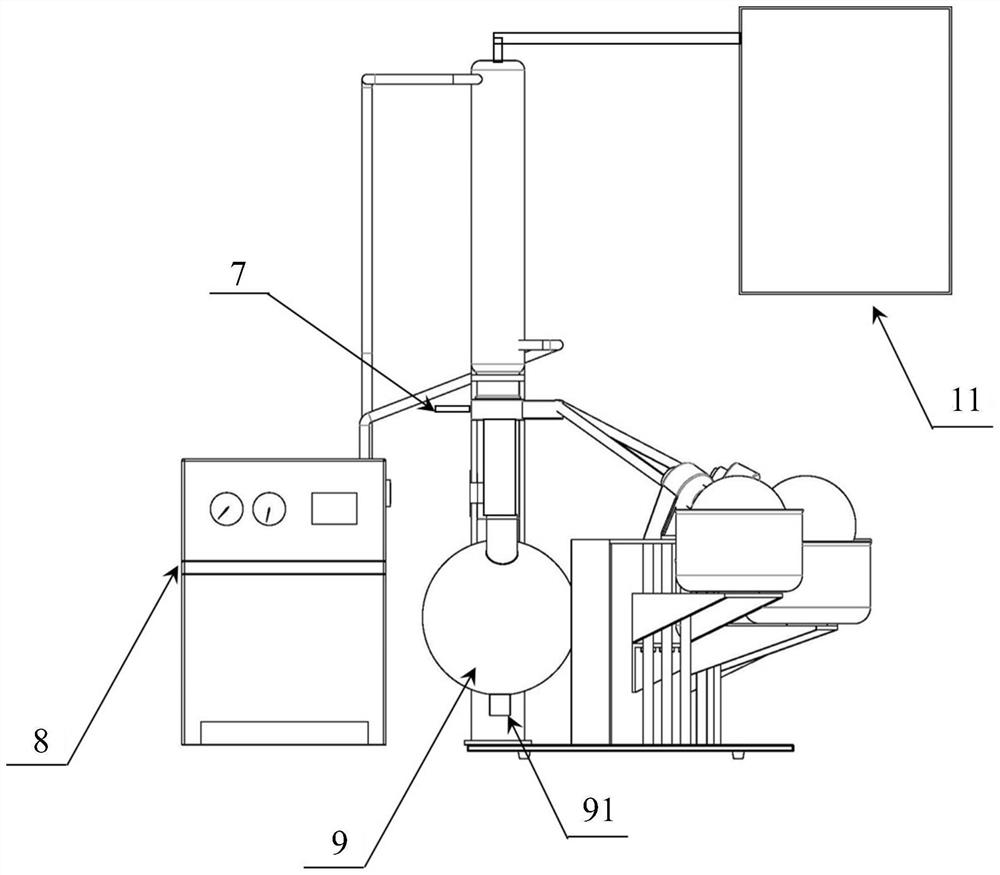

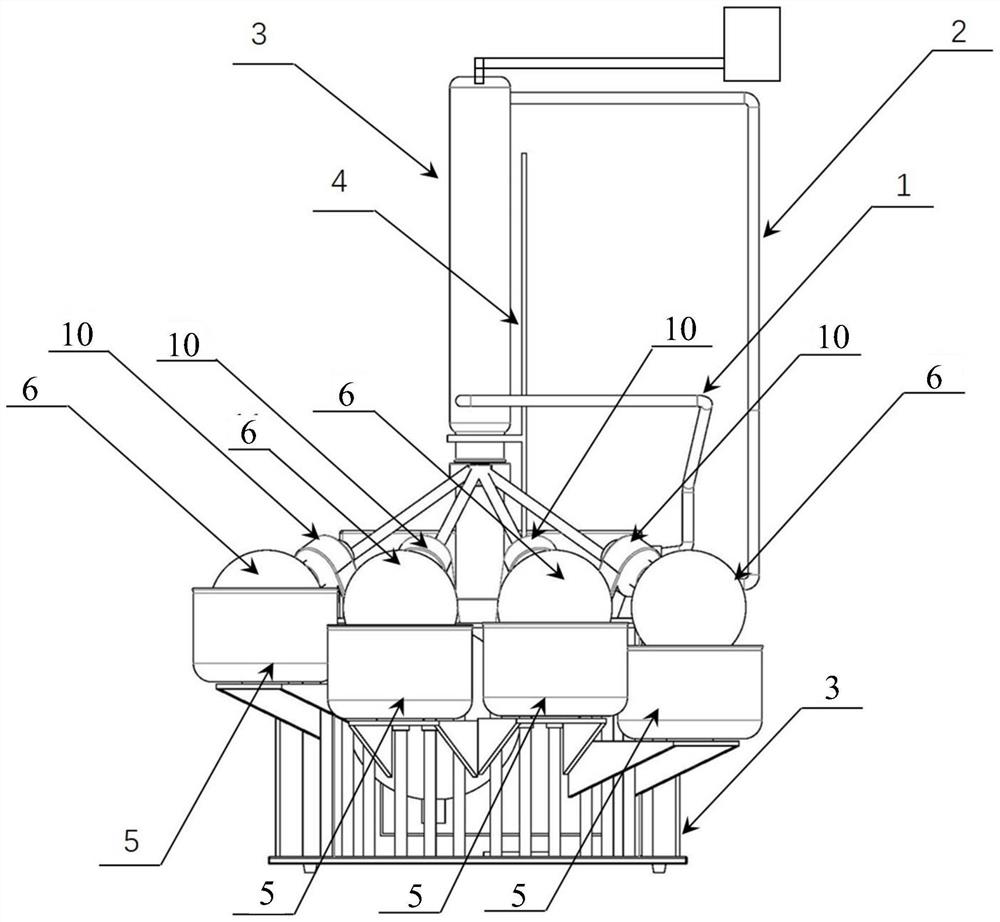

[0026] figure 1 and figure 2 It is a schematic diagram of a heating device for preparing samples according to an exemplary embodiment. like figure 1 and figure 2 As shown, the heating equipment for preparing samples may include: condensing equipment 8, a plurality of heating dishes 6, a plurality of heating pots 5, a vacuum device 11 and a waste liquid collection container 9;

[0027] In one example, the water samples to be treated can be pre-filled in each heating vessel 6 , and in addition, the container holding the environmental water samples can communicate with each heating vessel through a pipeline, so that the continuous addition of water samples can be realized.

[0028] Liquid is filled in each heating pot 5, and each heating dish 6 is immersed in the liquid of a heating pot 5, and each heating pot 5 can carry out water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com