Detection device and calibration method for electrode lifting system of LF furnace

A technology of electrode lifting and detection devices, which is applied in the field of refining, can solve the problems of control system stability, low efficiency, and poor control effect, and achieve the effect of reducing maintenance difficulty, reducing maintenance time, and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

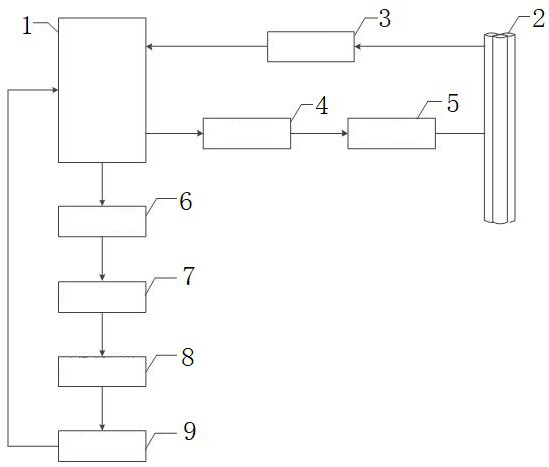

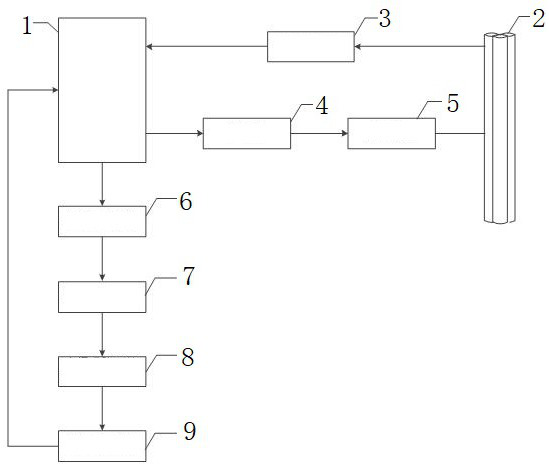

[0024] In order to overcome the problem that the replacement of the existing hydraulic servo valve or the change of the system pressure will cause the stability and high efficiency of the original control system to decrease, resulting in the deterioration of the control effect, the present invention provides such as figure 1 Shown is a detection device and calibration method for the electrode lifting system of an LF furnace. The present invention realizes the correction of the control output of the electrode regulator through the calibration of the electrode lifting system and avoids readjusting the parameters of the electrode regulator. This method reduces The difficulty of on-site maintenance provides a strong guarantee for the long-term, stable and efficient operation of the entire electrode regulator.

[0025] A detection device for an electrode lifting system of an LF furnace, comprising an electrode regulator 1 and an electrode 2, a proportional valve 4 and an electrode l...

Embodiment 2

[0030] Based on Embodiment 1, in this embodiment, preferably, the electrodes 2 are three-phase electrodes.

[0031] Preferably, the electrode lifting mechanism 5 includes at least a hydraulic cylinder and a conductive cross arm, and the hydraulic cylinder drives the conductive cross arm to move up and down.

[0032] Preferably, the end of the conductive cross arm is connected to the electrode 2 .

[0033] Preferably, the specific steps of determining the position of the electrode 2 are as follows: the electrode regulator 1 drives the valve core opening of the proportional valve 4 to control the upward or downward movement of the electrode 2 .

[0034] Preferably, the electrode position of the electrode 2 is fed back to the electrode regulator 1 through the electrode position detector 3; when the electrode position detector 3 is the same as the set position, the electrode regulator 1 stops controlling the proportional valve 4, so that it is connected with the electrode lifting ...

Embodiment 3

[0037] Based on Embodiment 1 or 2, in this embodiment, preferably, the lower end of the electrode regulator 1 is connected with a calibration system.

[0038] Preferably, the calibration system includes a data acquisition module 6, a data conversion module 7, an electrode lifting system model calibration module 8 and a data writing module 9; the data acquisition module 6 is connected to the data interface at the lower end of the electrode regulator 1 , the data writing module 9 is connected to the data interface on the left side of the electrode regulator 1; the data acquisition module 6 is used to collect the threshold value of the proportional valve 4, the detection value of the electrode position detector 3, the electrode regulator The control output time of 1 and the displacement of electrode 2; the data conversion module 7 is used to uniformly convert the collected data to the required format; the electrode lifting system model calibration module 8 will convert the data in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com