Efficient composite fluxing agent for improving melting characteristic of gasified pulverized coal slag

A kind of flux and high-efficiency technology, used in fuel additives, petroleum industry, fuel and other directions, can solve the problems affecting the stable operation of the gasifier, difficult to overcome the problem of slag blocking, and increase the ash content, so as to improve the viscosity-temperature characteristics and improve the melting point. Features, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

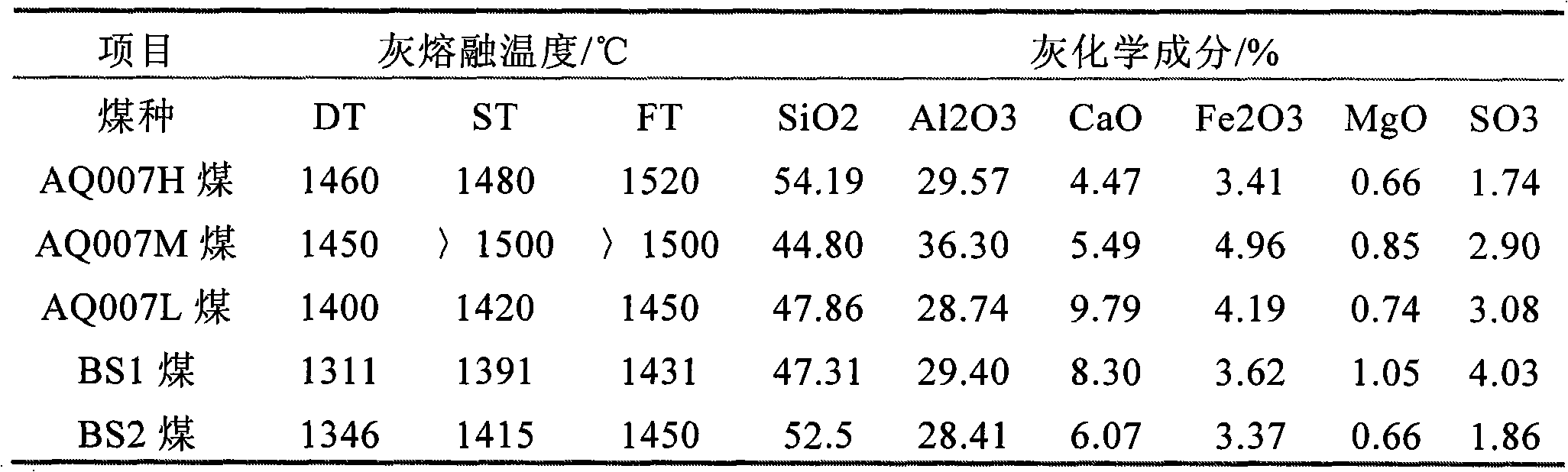

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: be 10% magnesium-containing ore powder by mass percent, 90% calcium-magnesium-containing ore powder fully mix and make flux, then with 2~6% (with coal as benchmark, quality is the coal of 100 parts The proportion of flux added in) is added to the Shell gasification coal, and mixed evenly.

Embodiment 2

[0020] Embodiment 2: being 20% magnesium-containing ore powder by mass percent, 80% calcium-magnesium-containing ore powder is fully mixed and made flux: then with 2~6% (based on coal, quality is 100 parts of coal The proportion of flux added in) is added to the Shell gasification coal, and mixed evenly.

Embodiment 3

[0021] Embodiment 3: being 30% magnesium-containing ore powder by mass percent, 70% calcium-magnesium-containing ore powder fully mixes and makes flux, then with 2~6% (taking coal as benchmark, quality is 100 parts of coal The proportion of flux added in) is added to the Shell gasification coal, and mixed evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com