Liquid level sensor prepared based on plastic optical fiber macro-bending method

A technology of liquid level sensor and light modeling, which is applied in the direction of liquid level indicators, instruments, mechanical equipment, etc., can solve the problems of temperature, electromagnetic, liquid type pollutants, unsuitable vibration environment, expensive instruments and equipment, etc., to achieve Excellent processability and insulation, light weight and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

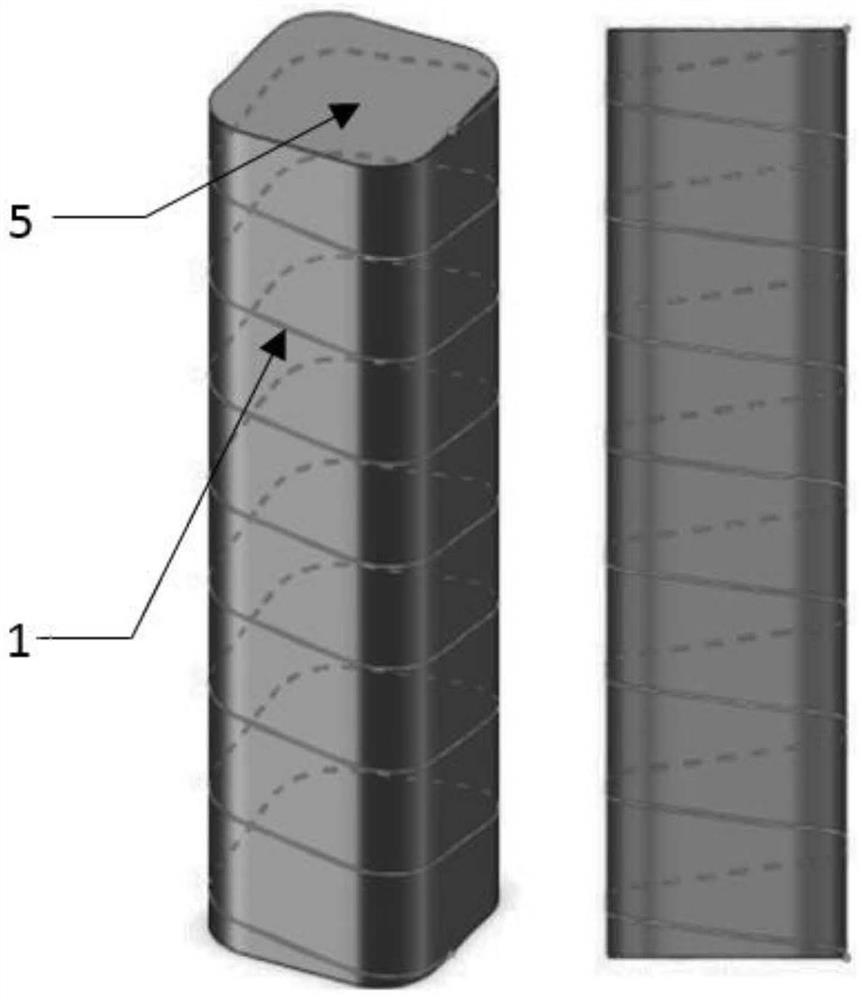

[0040] The cylinder used in the embodiment is a square cylinder with rounded corners, the height of the cylinder is 100mm, the length of the straight section of the bottom surface is 4mm, and the bending radius is 2mm; the POF used is d500 produced by Jiangxi Dasheng Plastic Optical Fiber Co., Ltd.;

[0041] The core material of the d500 is PMMA, the cladding material is fluororesin, the refractive indices of the core and the cladding are 1.49 and 1.41 respectively, the core diameter is 480 μm, and the cladding thickness is 10 μm.

[0042] A liquid level sensor prepared based on plastic optical fiber macro-bending method, the specific steps are as follows:

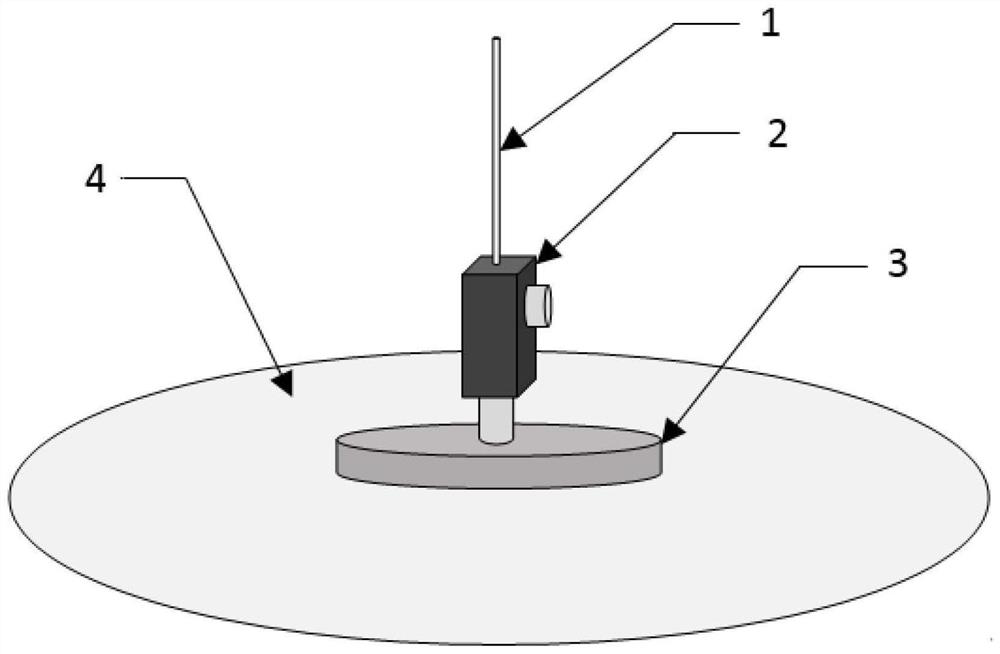

[0043] Select a plastic optical fiber with a diameter of 1 m and a diameter of 500 μm, and polish the surfaces at both ends to ensure the parallelism and flatness of the upper and lower surfaces, such as figure 1 As shown; put the polished fiber end face into a beaker filled with alcohol, ultrasonically clean it and then d...

Embodiment 2

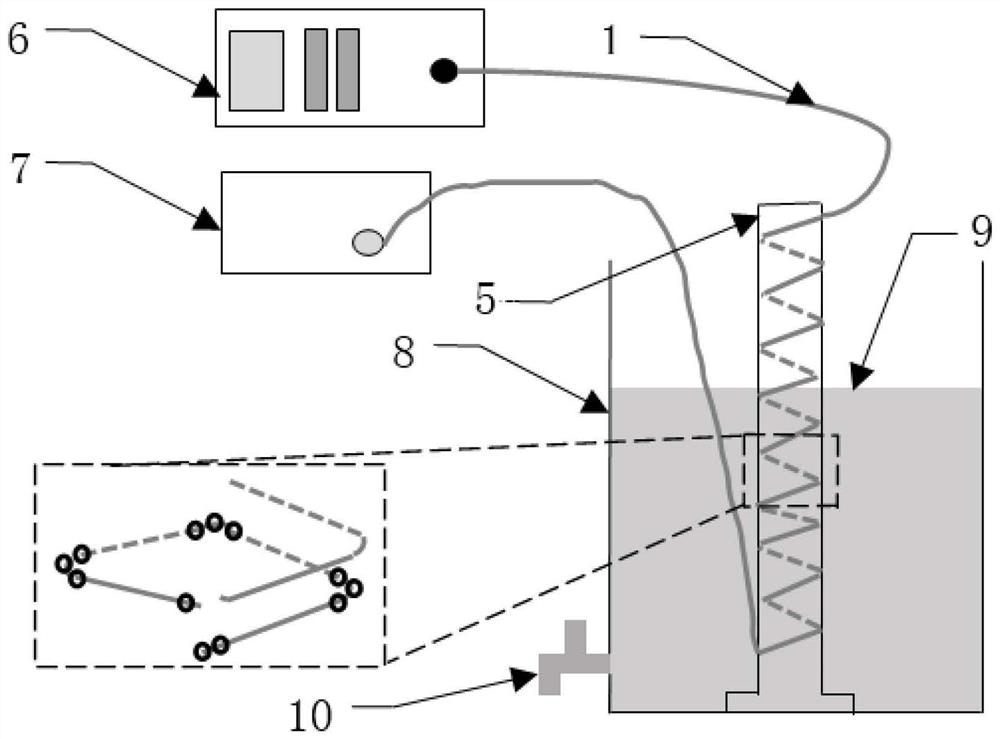

[0047] The difference from Example 1 is that in Example 2, the sensor after standing for 48 hours is placed in a water bath and heated at a constant temperature of 50°C for 12 hours to eliminate the internal stress when the optical fiber is wound, and the other conditions are the same as in Example 1. . Compared with Example 1, the sensitivity of the sensor is slightly reduced, but the repeatability and reliability of the sensor are greatly improved, as Figure 5 shown. The response time of each group was less than 100ms.

Embodiment 3

[0049] The difference from Example 1 is that plastic optical fibers with diameters of 250 μm (POF #1) and 1 mm (POF #2) are selected to build liquid level sensor experimental platforms, and other conditions are the same as in Example 1. Compared with Example 1, the liquid level sensor built with POF#1 has low sensitivity and cannot respond sensitively to changes in the liquid level; the liquid level sensor built with POF#2 has too large a POF size, and POF is not in contact with the surface of the cylinder. Completely, the sensor preparation is difficult, and the repeatability of liquid level monitoring is poor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com