Programmable oil well mouth controller and control method thereof

A control method and controller technology, applied in pump control, wellbore/well components, earthwork drilling, etc., can solve the problems of poor reliability, single function, inconvenient user expansion, etc., to achieve high reliability and meet personnel safety. , expand the effect of convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

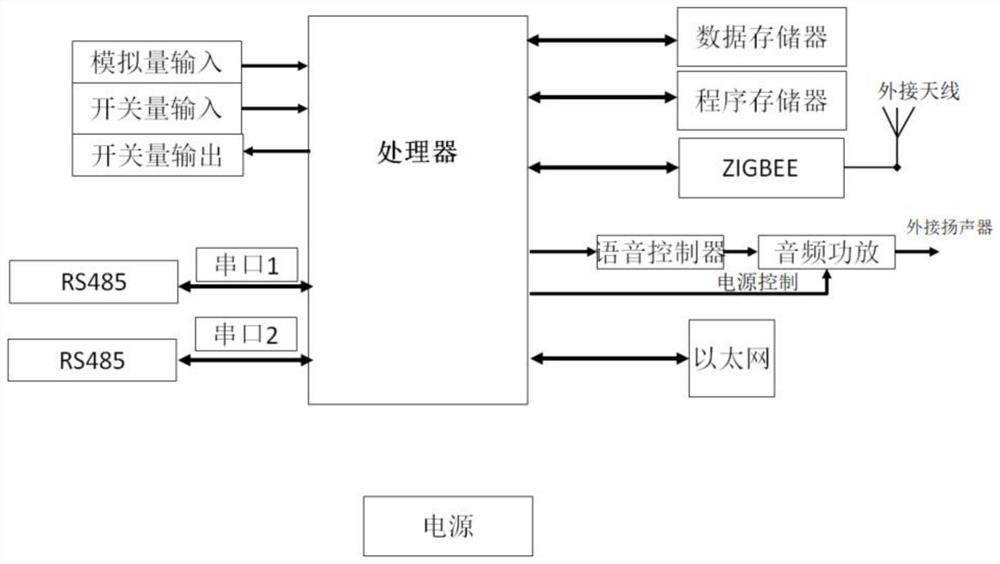

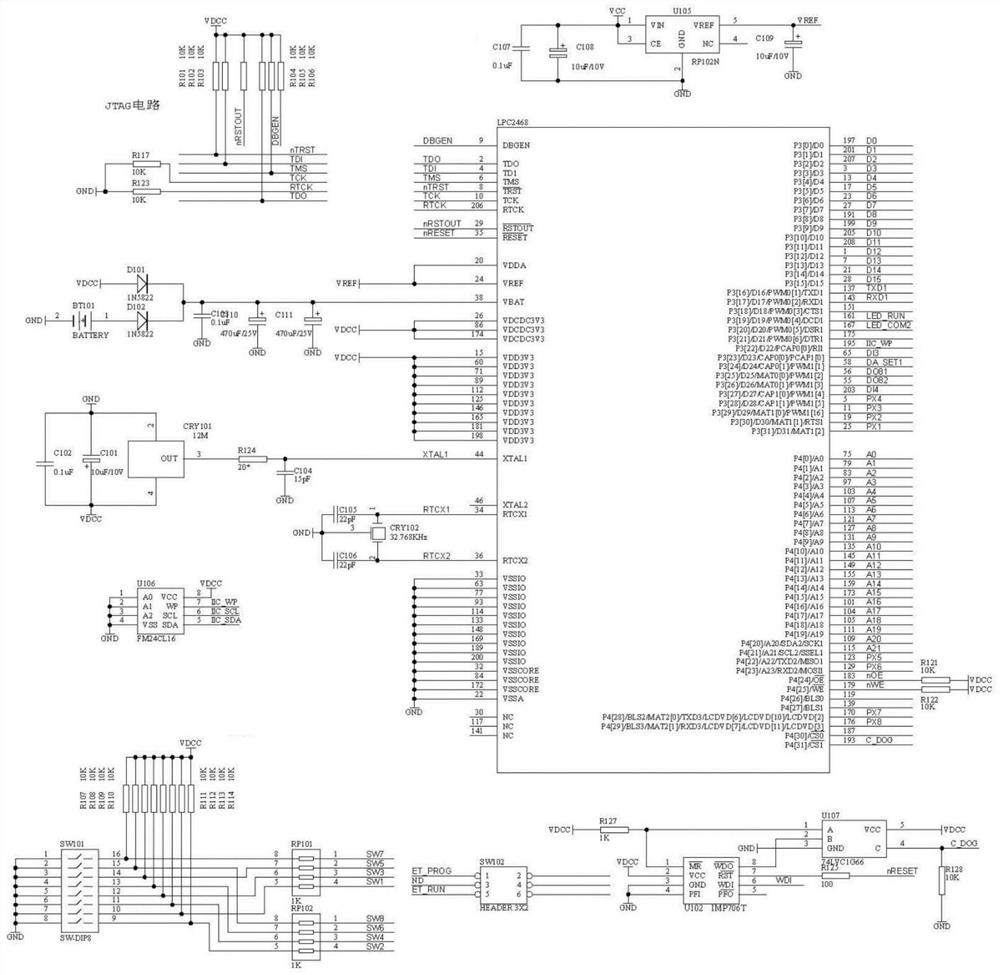

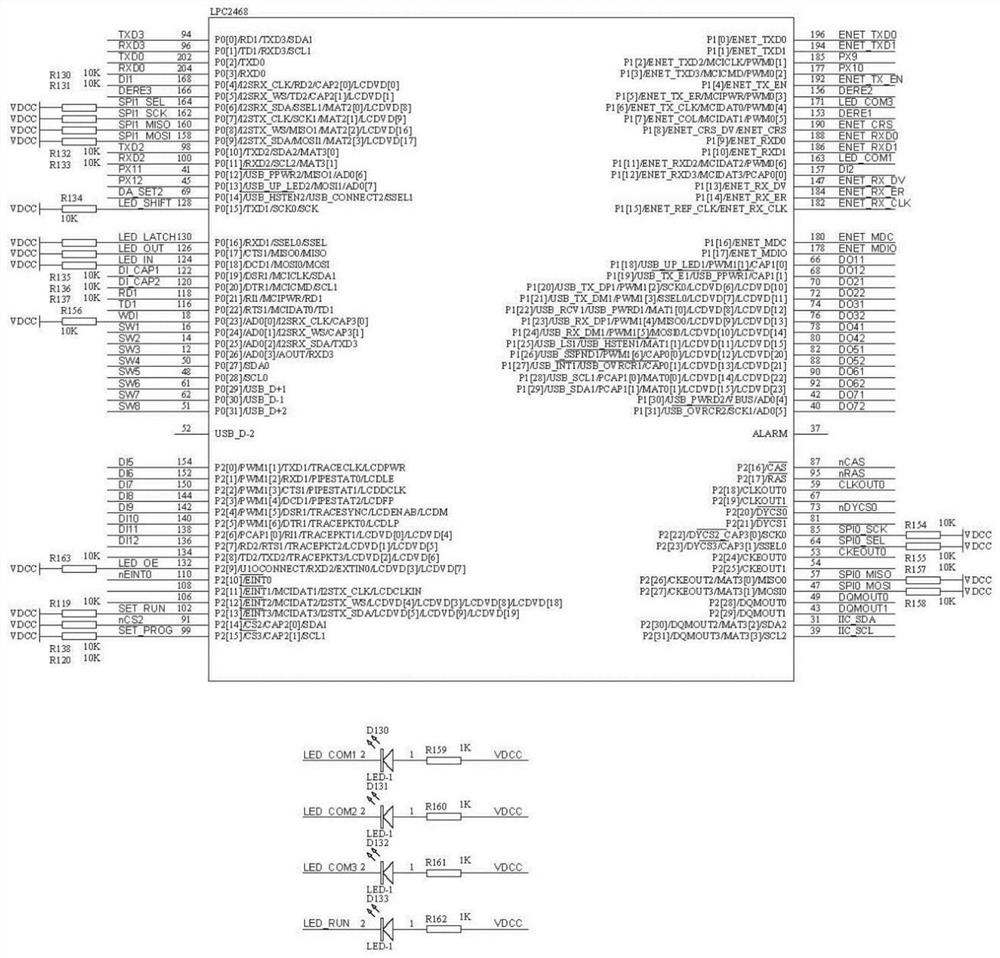

Embodiment 1

[0039] see Figure 1-10, a programmable oil well wellhead controller, which includes a processor, a data memory, a program memory, a data communication interface, an RS485 bus communication interface, a ZIGBEE wireless interface, an analog signal input circuit, a switch signal input and output circuit, and a voice controller and audio power amplifier; the data memory and the program memory are connected to the processor, and the two memories are used for data interaction, program download and program debugging with an external host computer; the data communication interface is connected to the processor Connected, the data communication interface is used for the transmission of operation data; the RS485 bus communication interface is connected with the processor, and the RS485 bus communication interface is used for communication with the frequency converter and the intelligent power meter unit; the ZIGBEE wireless interface is connected with the processing The ZIGBEE wireless...

Embodiment 2

[0054] When programming the programmable oil well head controller in the first embodiment, the system adopts a real-time operating system, built-in protocol stack and file system, etc., and the software is written in C language. The system has a built-in IEC61131-3 running, downloading, and debugging environment. Through the Ethernet port, the controller can be programmed. The programming environment and operating environment support five types of programming defined by IEC61131-3: IL, LD, ST, FBD, and SFC. language. The programming environment converts the five programming languages defined by IEC61131-3, IL, LD, ST, FBD and SFC, into intermediate codes, which are then compiled into machine codes by the compiler and can be directly run on the processor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com