3D curve welding seam autonomous demonstration method for welding robot based on linear structure light perception

A welding robot and line structured light technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low speed and low precision, improve effectiveness, meet safety, improve speed and The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

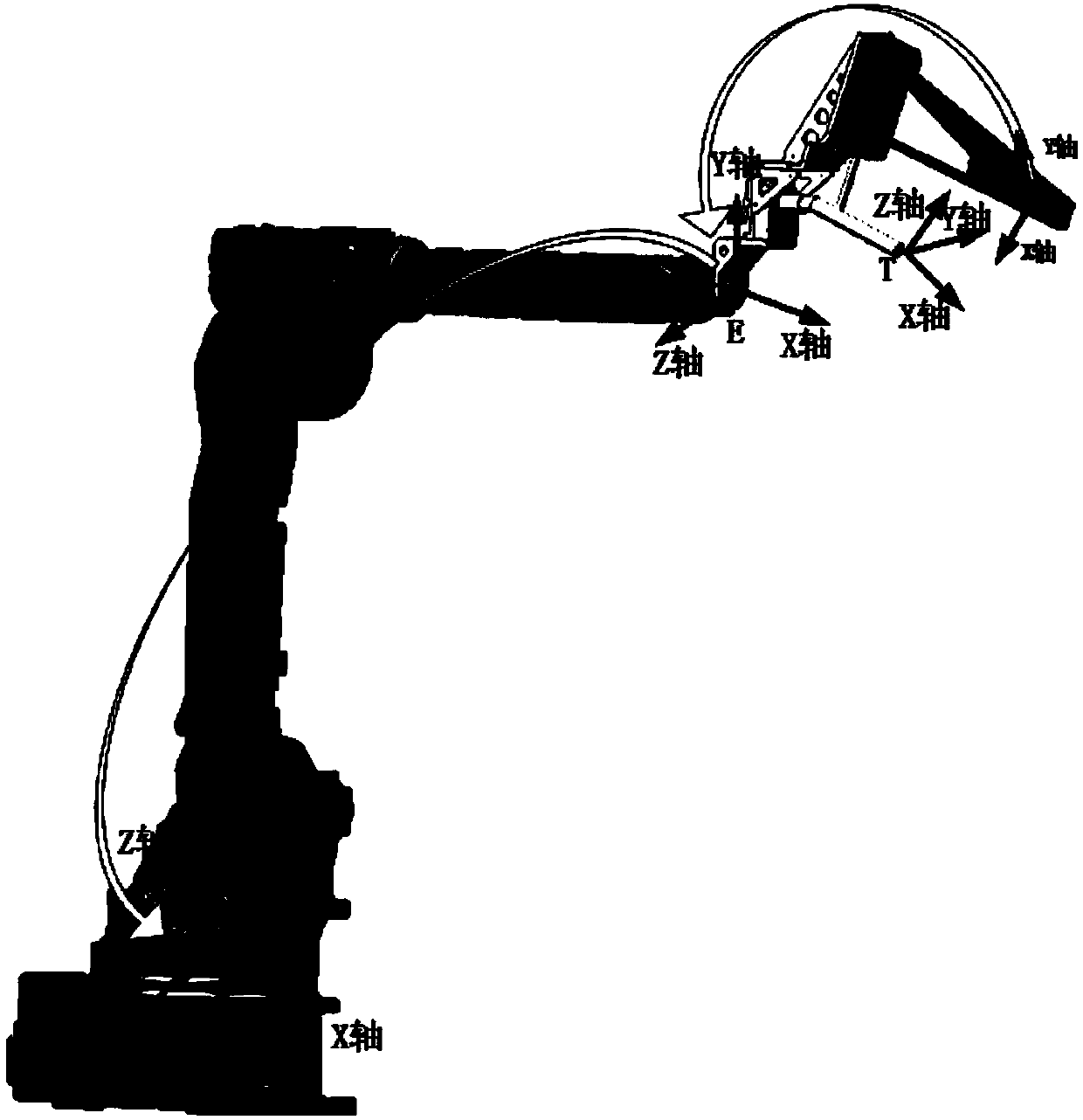

[0064] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0065] It should be pointed out that those skilled in the art can make some improvements and modifications without departing from the principle of the present invention, and these improvements and modifications should also be regarded as the protection scope of the present invention. All components that are not specified in this embodiment can be realized by existing technologies.

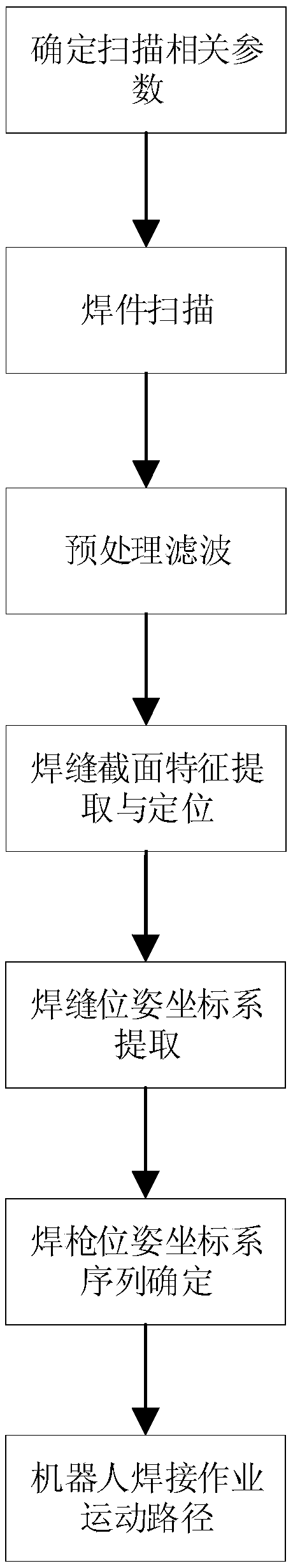

[0066] Such as figure 1 As shown, a method for autonomous teaching of a welding robot 3D curve weld seam based on line structured light perception of the present invention includes the following steps:

[0067] 1. Determine the scanning related parameters, and scan to generate an ordered point cloud model of the weldment

[0068] Among them, the relevant parameters include the starting pose of the scan, the scan distance, the scan direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com