Molybdenum disulfide film with consistent grain orientation height and preparation method thereof

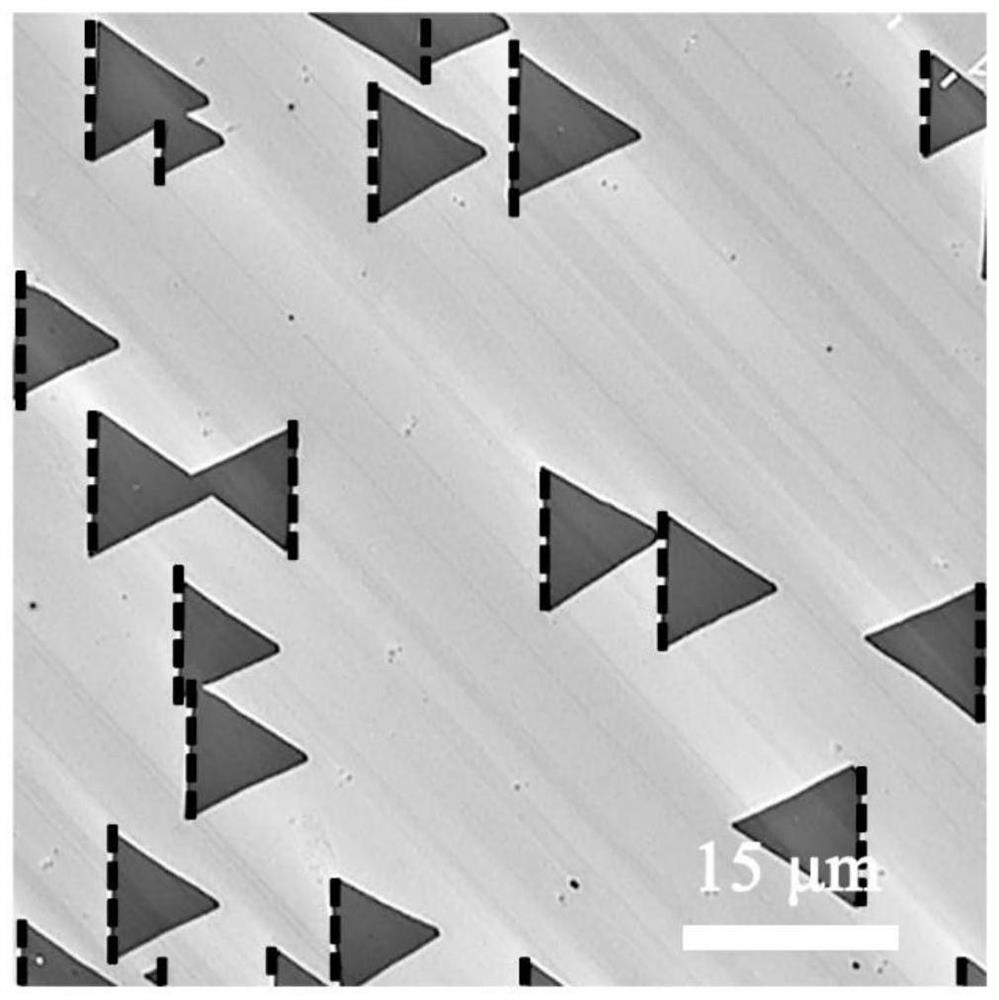

A technology of molybdenum disulfide and crystal orientation, applied in the field of two-dimensional materials, can solve the problems of reducing carrier mobility, negative impact on electrical and optical properties, etc., and achieve less strain and defects, less grain boundaries, and high electron mobility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

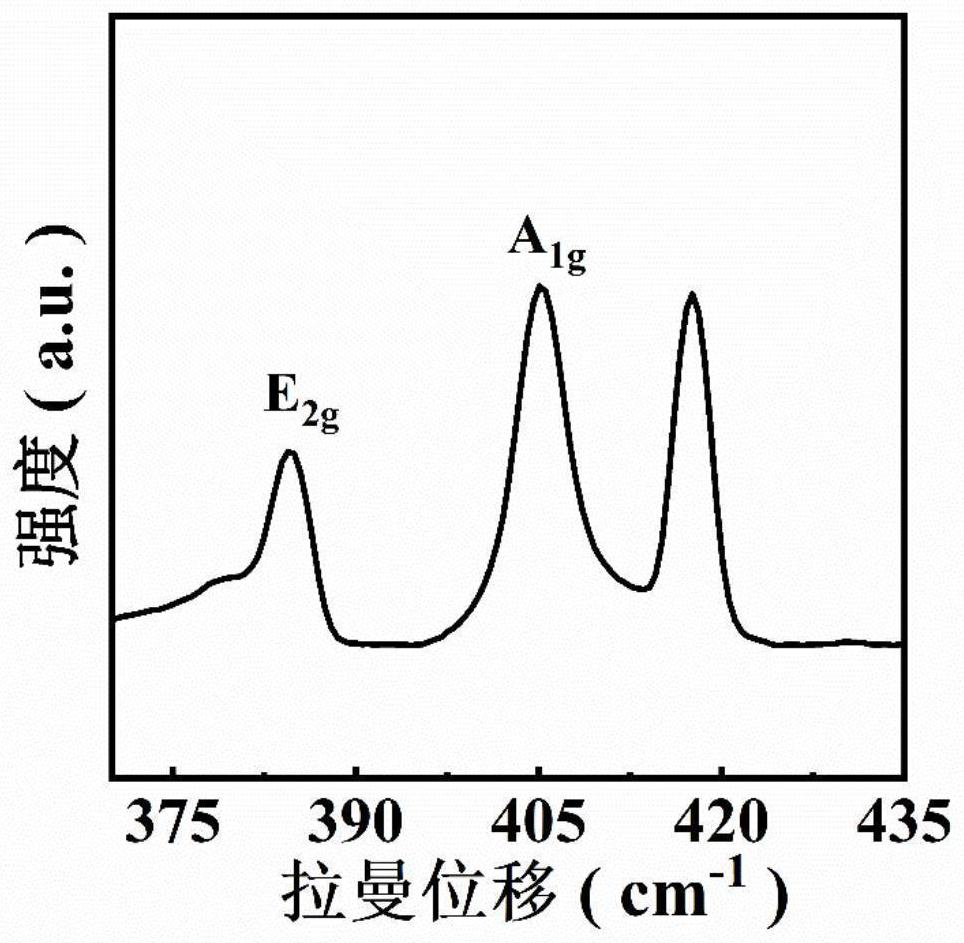

Examples

Embodiment 1

[0033] (1) Place the sapphire substrate in acetone, ethanol, and deionized water for 10 minutes for ultrasonic cleaning, and then dry it with dry nitrogen. Clean the quartz boat with the same cleaning method, place it in acetone, ethanol, and deionized water for 10 minutes, and then blow it dry with dry nitrogen.

[0034] (2) The c-plane sapphire substrate is annealed at high temperature (1000°C) for 1 hour in air to obtain atomically flat steps along the specific crystal direction.

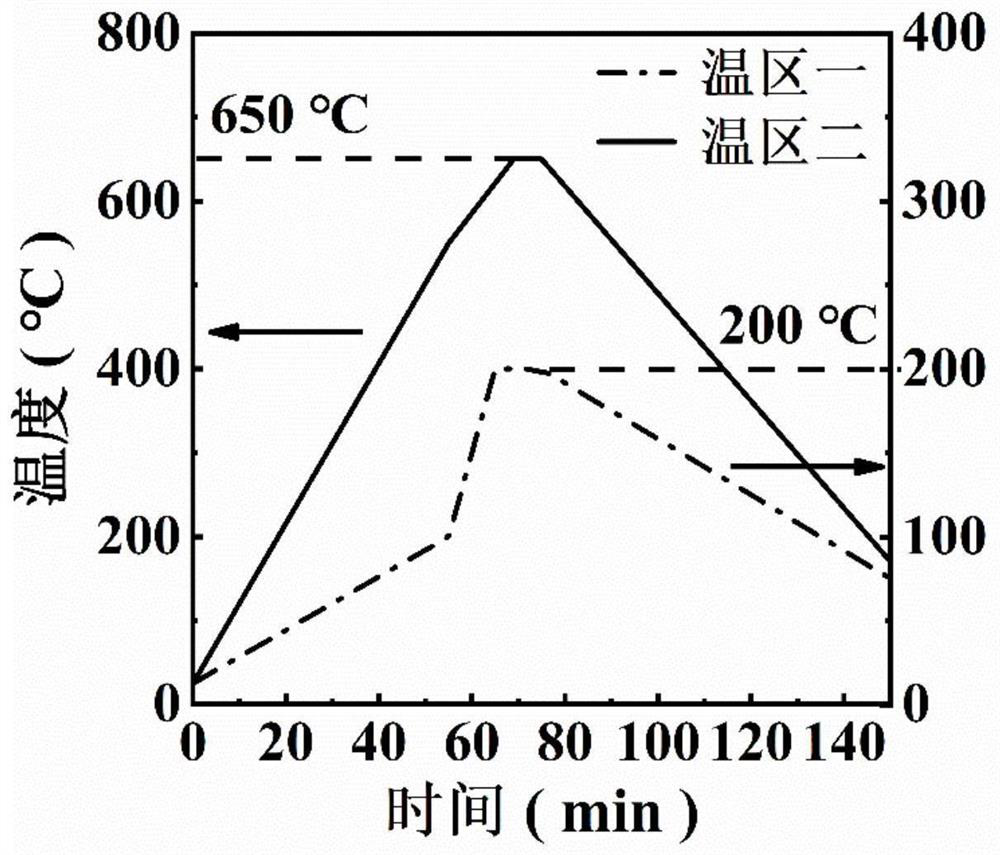

[0035] (3) Weigh the precursor with a weighing balance. Weigh 6mg of MoO 3 The powder and the NaCl powder of 3mg were mixed evenly, and the two were ground for 10 minutes and then placed in the second temperature zone. The annealed sapphire is also placed in the second temperature zone, downstream of the carrier gas at a distance of 5 cm from the Mo source. Weigh 138 mg of S powder and place it in the first temperature zone.

[0036] (4) Before heating up the tube furnace, vacuumize the quar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com