Silver nanosheet cluster array and preparation method and application thereof

A technology of silver nanosheets and arrays, which is applied in the field of silver nanomaterials and preparation, can solve the problems that it is difficult to realize the controllable adjustment of the LSPR absorption peak of the silver nanosheet structure, it is not conducive to the repeatability of SERS signals, and the preparation method cannot be overcome, etc., to achieve SERS High hotspot density, simple and easy method, and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for preparing a silver nanosheet cluster array, the specific steps are:

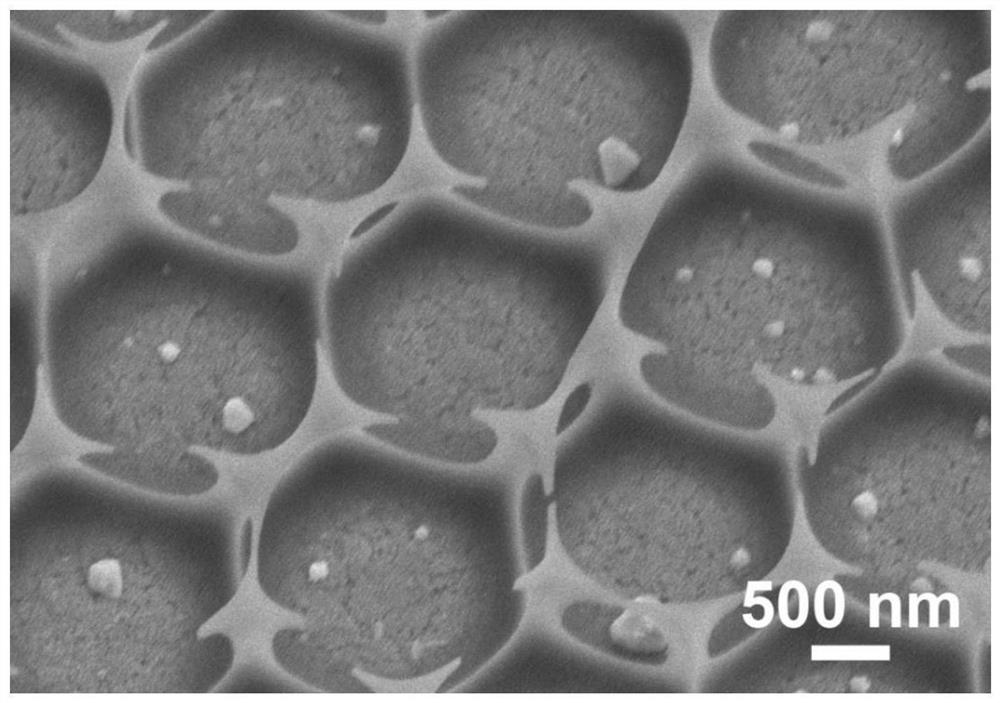

[0039] Step 1: Use the liquid surface self-assembly method to obtain a single-layer close-packed microsphere array template composed of polystyrene microspheres with a diameter of 2 microns, and then use the liquid surface floating method to transfer the single-layer polystyrene bead template to the surface by The ion sputtering method sputters the conductive substrate surface with gold nanoparticles;

[0040]Step 2: Put the conductive substrate sputtered with gold nanoparticles on the surface and laying a single layer of polystyrene beads in an oven with an internal temperature of 110°C for 10 minutes, so that the polystyrene beads are firmly attached to the conductive substrate surface, and the adjacent polystyrene balls are connected to each other; then the conductive substrate is taken out, and an aqueous solution of aluminum nitrate with a concentration of 0....

Embodiment 2

[0046] This embodiment provides a method for preparing a silver nanosheet cluster array, the specific steps are:

[0047] Step 1: Use the liquid surface self-assembly method to obtain a single-layer close-packed microsphere array template composed of polystyrene microspheres with a diameter of 2 microns, and then use the liquid surface floating method to transfer the single-layer polystyrene bead template to the surface by The ion sputtering method sputters the conductive substrate surface with gold nanoparticles;

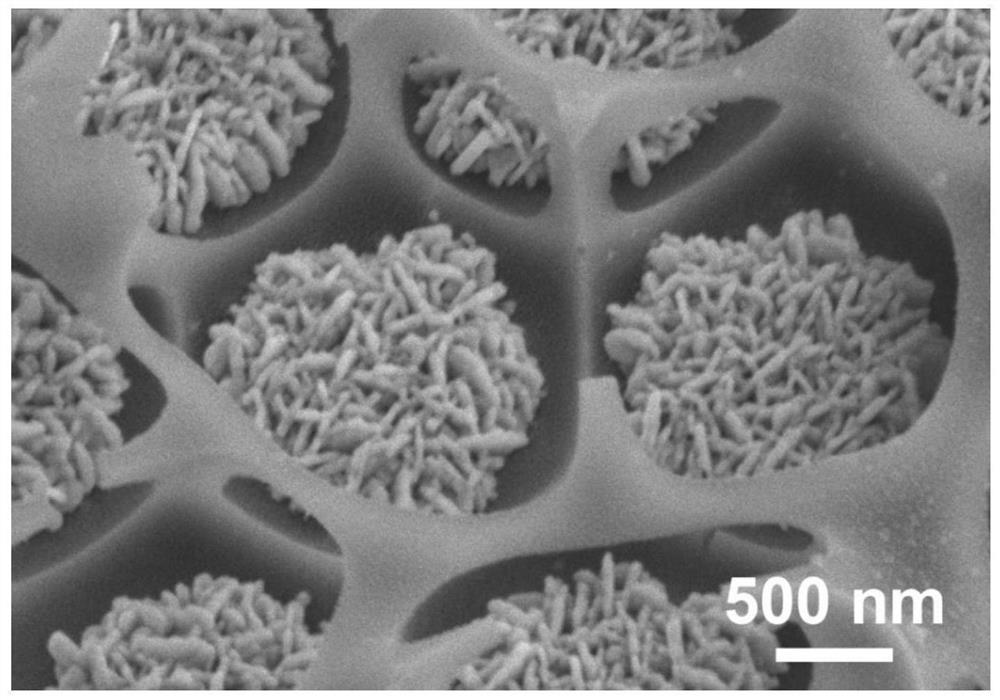

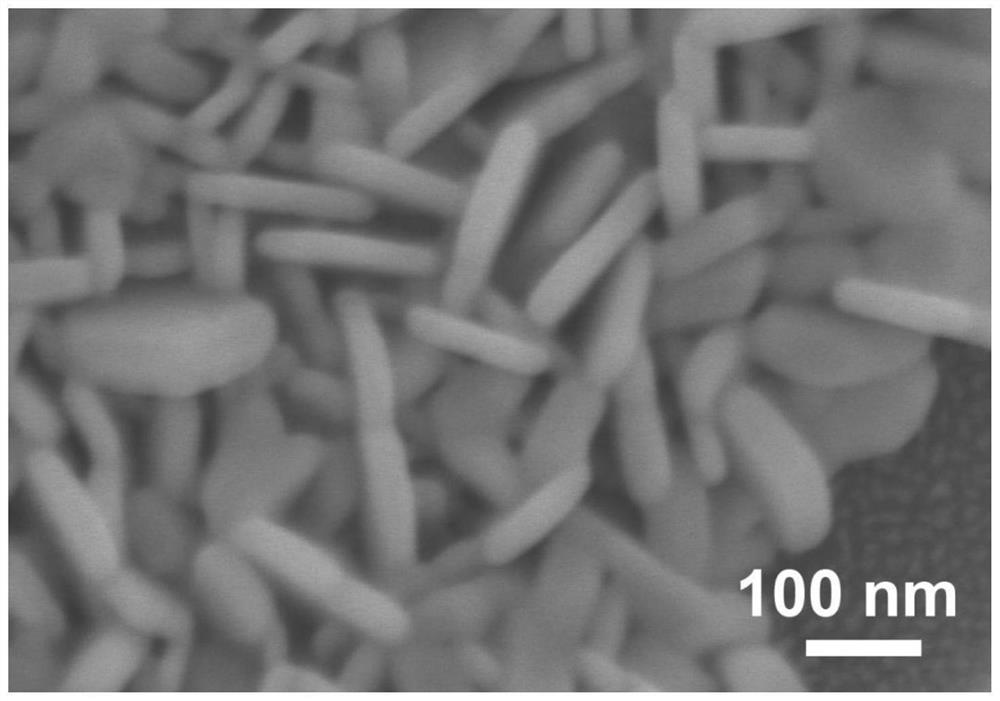

[0048] Step 2: Put the conductive substrate sputtered with gold nanoparticles on the surface and laying a single layer of polystyrene beads in an oven with an internal temperature of 110°C for 10 minutes, so that the polystyrene beads are firmly attached to the conductive substrate surface, and adjacent polystyrene spheres are connected to each other; then the conductive substrate covered with polystyrene microsphere arrays is placed in a plasma etching machine, an...

Embodiment 3

[0053] This embodiment provides a method for preparing a silver nanosheet cluster array, the specific steps are:

[0054] Step 1: Use the liquid surface self-assembly method to obtain a single-layer close-packed microsphere array template composed of polystyrene microspheres with a diameter of 2.5 microns, and then use the liquid surface floating method to transfer the single-layer polystyrene bead template to the surface by The ion sputtering method sputters the conductive substrate surface with gold nanoparticles;

[0055] Step 2: Put the conductive substrate sputtered with gold nanoparticles on the surface and laying a single layer of polystyrene beads in an oven with an internal temperature of 110°C for 10 minutes, so that the polystyrene beads are firmly attached to the conductive substrate surface, and adjacent polystyrene spheres are connected to each other; then the conductive substrate covered with polystyrene microsphere arrays is placed in a plasma etching machine, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com