High-performance bridge steel with yield strength not smaller than 500 MPa and preparation method and application of high-performance bridge steel

A technology with yield strength and high performance, applied in the field of metallurgy, can solve the problems of high preparation cost and low yield strength, and achieve the effect of low cost, simple composition design and excellent welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

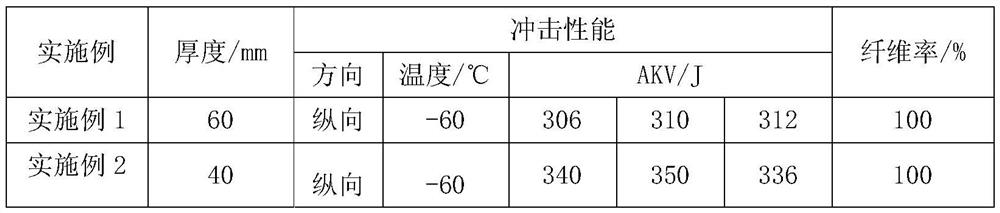

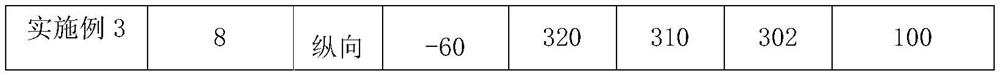

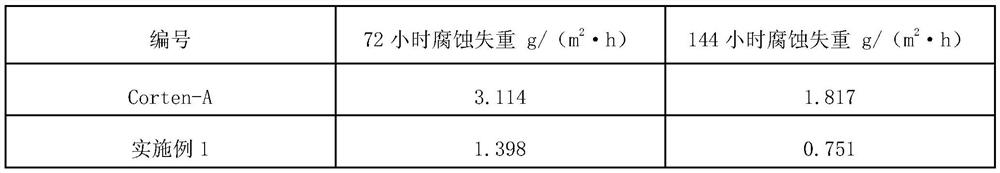

Embodiment 1

[0043] The chemical composition of the bridge steel described in this example is as follows: C: 0.05%, Si: 0.21%, Mn: 1.48%, P: 0.010%, S: 0.002%, Al: 0.03%, Cr: 0.40%, MO: 0.15%, Cu: 0.27%, Ni: 0.32%, Nb: 0.035%, Ti: 0.018%, the rest is FE and inevitable impurities. The bridge steel finished product has a thickness of 60 mm.

[0044] The preparation method of bridge steel according to the present embodiment, the feedstock is obtained by smelting, refining, alloying, calcium treatment, and finally cast into a cast blank. Specifically, the following steps:

[0045] 1) Smelting converter uses the top-bottom pressure, sufficiently decaplation, dephosphorization, endpoint carbon content 0.007%; LF for microalloy, 0.04% end-point carbon, 0.009% phosphorus content, microorin content Add to target value The RH vacuum reached 133 Pa or less, the holding time was 14 min, the purification time was 10 min, the soft blowing time was 15 min, and the sedative time was 35 min after RH treatment....

Embodiment 2

[0052] The chemical composition of bridge steel as described in this example is as follows: C: 0.05%, Si: 0.20%, Mn: 1.40%, P: 0.010%, S: 0.002%, Al: 0.03%, Cr: 0.32%, MO: 0.12%, Cu: 0.25%, Ni: 0.30%, Nb: 0.032%, Ti: 0.018%, the rest is Fe and inevitable impurities. The bridge steel finished product has a thickness of 40 mm.

[0053] The preparation method of bridge steel according to the present embodiment, the feedstock is obtained by smelting, refining, alloying, calcium treatment, and finally cast into a cast blank. Specifically, the following steps:

[0054] 1) Smelting converter uses the top-bottomed pressure, sufficiently decarbonation, dephosphorization, endpoint carbon content of 0.008%; LF for microorption, 0.04% of the endpoint carbon, 0.010% phosphorus content, microorin content Add to target value The RH vacuum reached 133 Pa or less, the pressure main pressure time was 14 min, the purification time was 9 min, the soft blow time was 13min, and the calm time was 34 min...

Embodiment 3

[0061] The chemical composition of the 8 mm high-performance bridge steel in this example is as follows: C: 0.04%, Si: 0.20%, Mn: 1.35%, P: 0.010%, S: 0.003%, Al: 0.031%, Cr: 0.30%, MO : 0.12%, Cu: 0.25%, Ni: 0.30%, Nb: 0.038%, Ti: 0.016%, the rest is FE and inevitable impurities. The bridge steel finished product has a thickness of 8 mm.

[0062] The preparation method of bridge steel according to the present embodiment, the feedstock is obtained by smelting, refining, alloying, calcium treatment, and finally cast into a cast blank. Specifically, the following steps:

[0063] 1) Smelting converter uses the top-bottom pressure, sufficiently decarburized, dephosphorized, endpoint carbon content 0.007%; LF for microorption, endpoint carbon 0.009%, phosphorus content, add to the target value The RH vacuum reached 133 Pa or less, the pressure time was 146 min, the purification time was 10 min, the soft blow time was 14 min, and the sedative time was 32 min after RH treatment.

[0064]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com