Maotai-flavor liquor brewing device and brewing process

A brewing device and liquor technology, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of reduced wine quality, slow evaporation of raw materials, and inconvenient manual operation, and achieve the effects of improving mixing uniformity, accelerating evaporation, and avoiding internal deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

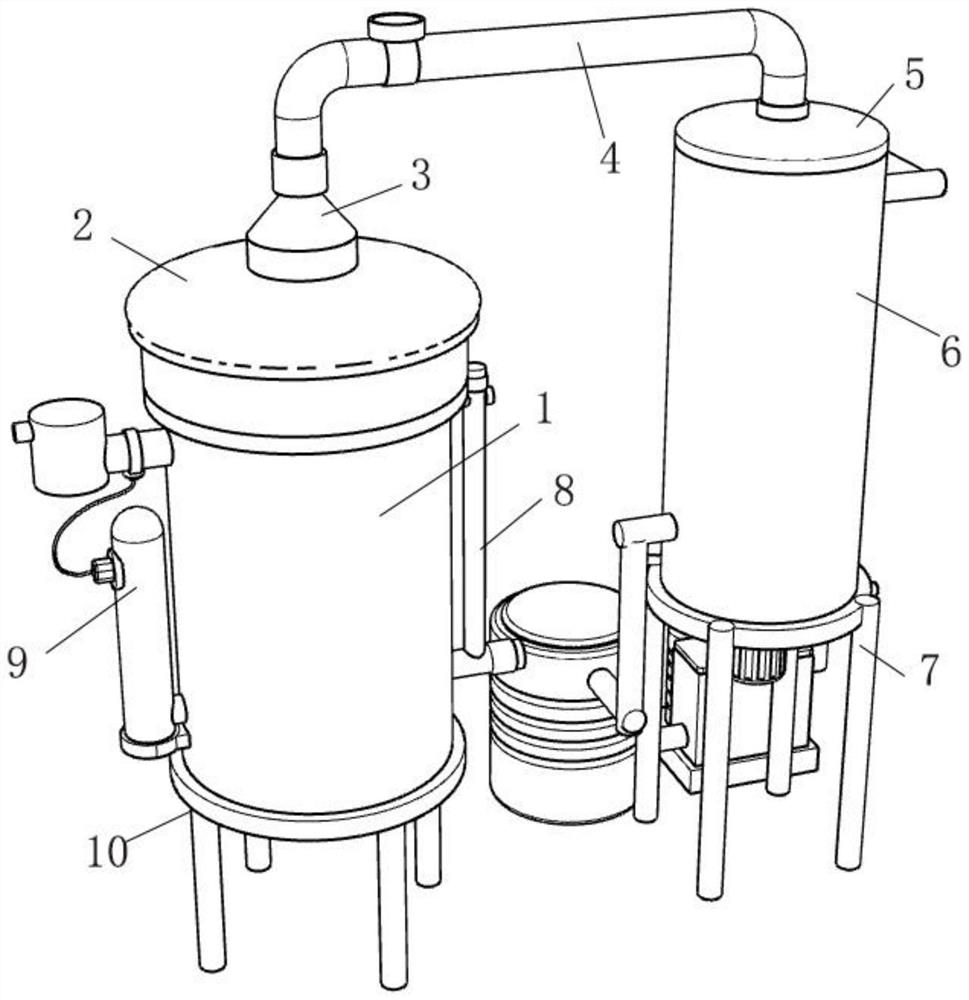

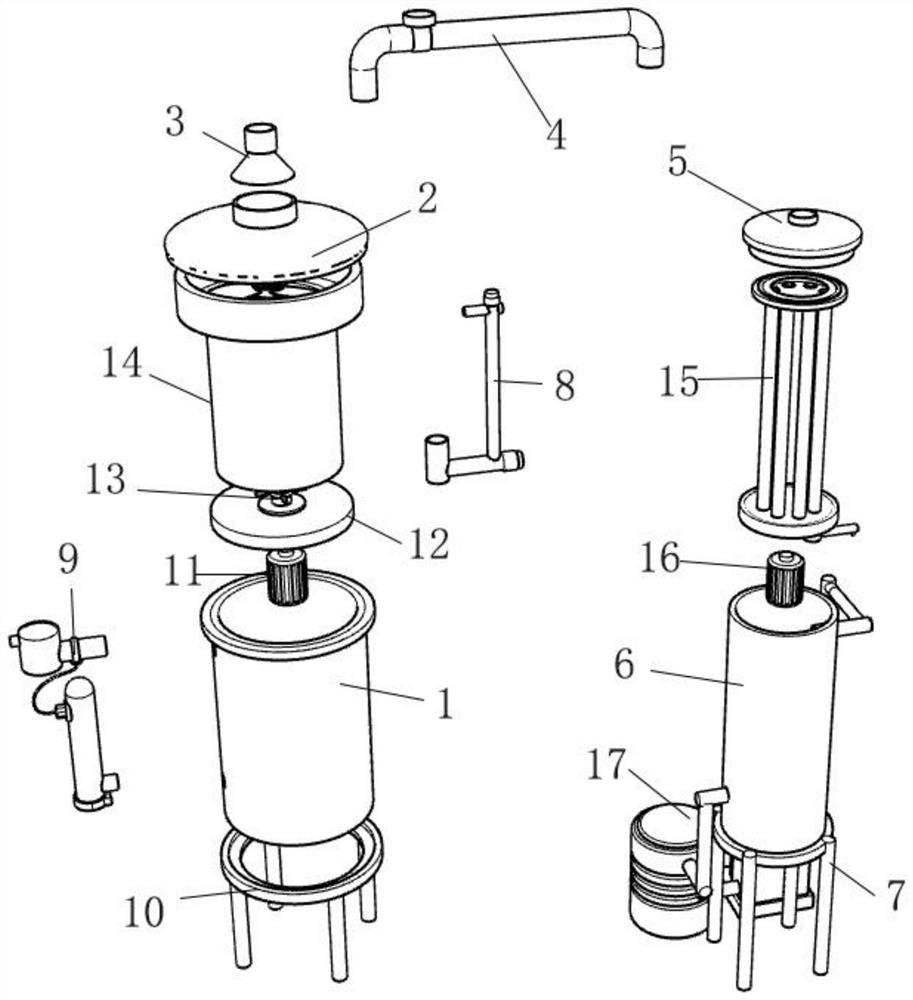

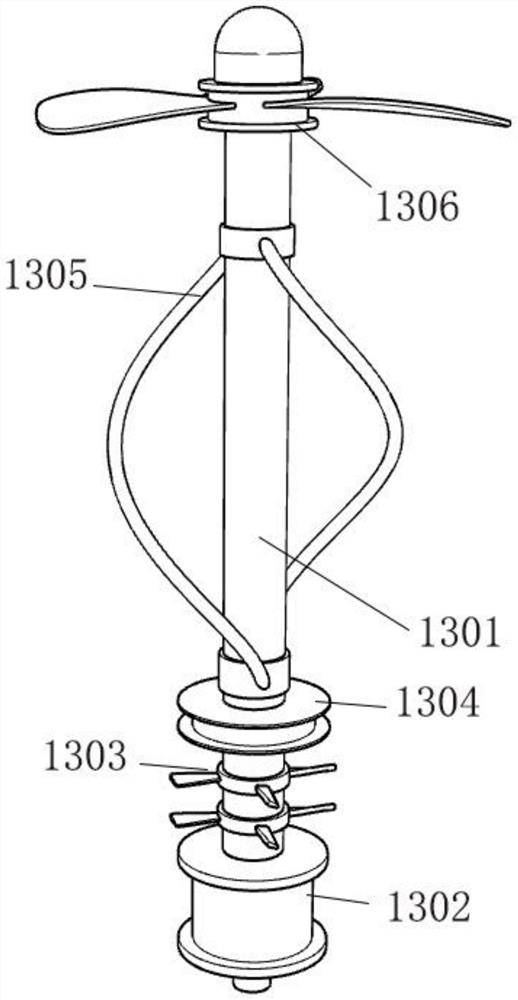

[0030] Embodiment one: refer to figure 1 and figure 2 , the invention provides a Maotai-flavor liquor brewing device, comprising an outer boiler 1, and also comprising:

[0031] Inner boiler 14: an inner boiler 14 is provided inside the outer boiler 1;

[0032] Top cover 2: the top of the inner boiler 14 is provided with a top cover 2;

[0033] Filter cartridge 3: the top of the top cover 2 is provided with a filter cartridge 3;

[0034] Transmission pipe 4: the top of the filter cartridge 3 is provided with a transmission pipe 4;

[0035] Air connection cover 5: the bottom of the transmission pipe 4 is provided with an air connection cover 5;

[0036] Condensing cylinder 6: the bottom of the connecting air cover 5 is provided with a condensing cylinder 6;

[0037] refer to figure 1 , the bottom of the outer boiler 1 is fixedly connected with a second tripod 10, the inside of the outer boiler 1 is fixedly connected with an inner boiler 14, the top of the inner boiler 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com