Water-based antistatic acrylic resin and preparation method thereof

A water-based acrylic, acrylic resin technology, applied in conductive coatings, coatings, etc., can solve the problems of light transmittance, transparency, poor performance, excessive tearing voltage, etc., to achieve excellent antistatic performance, air and water The effect of stable and excellent antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

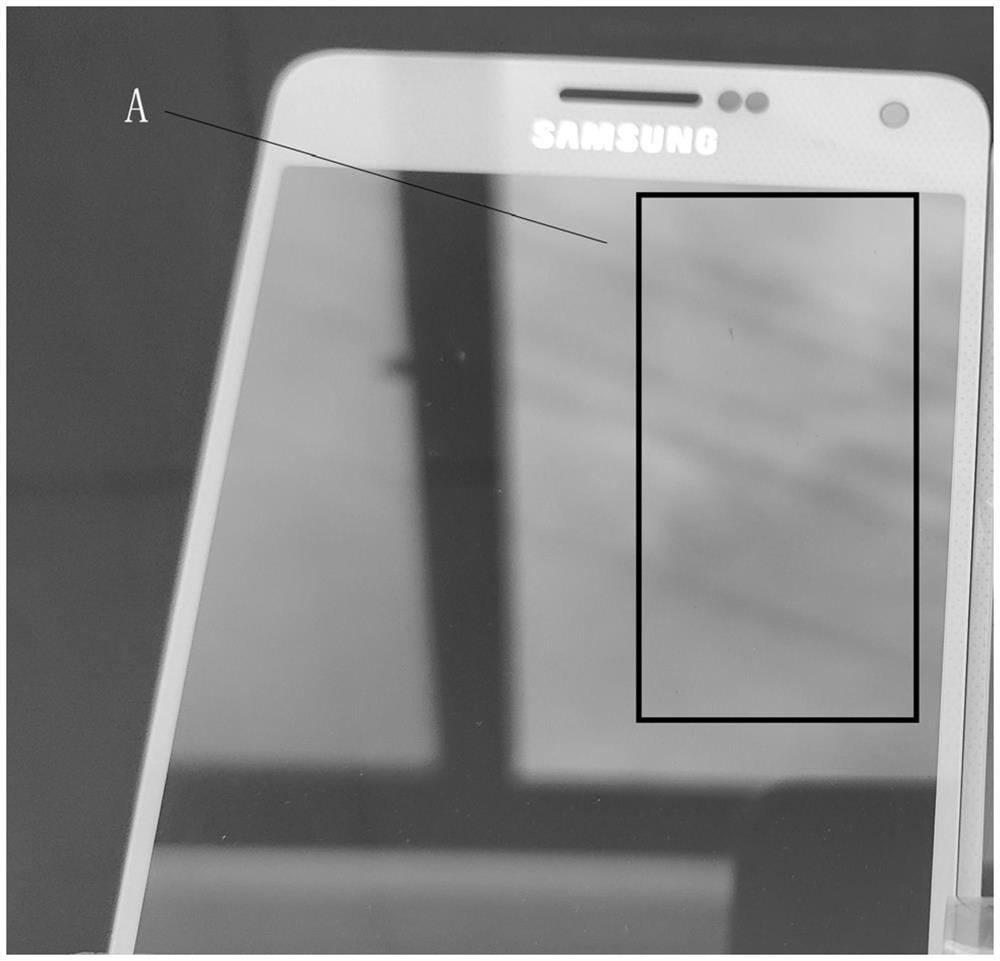

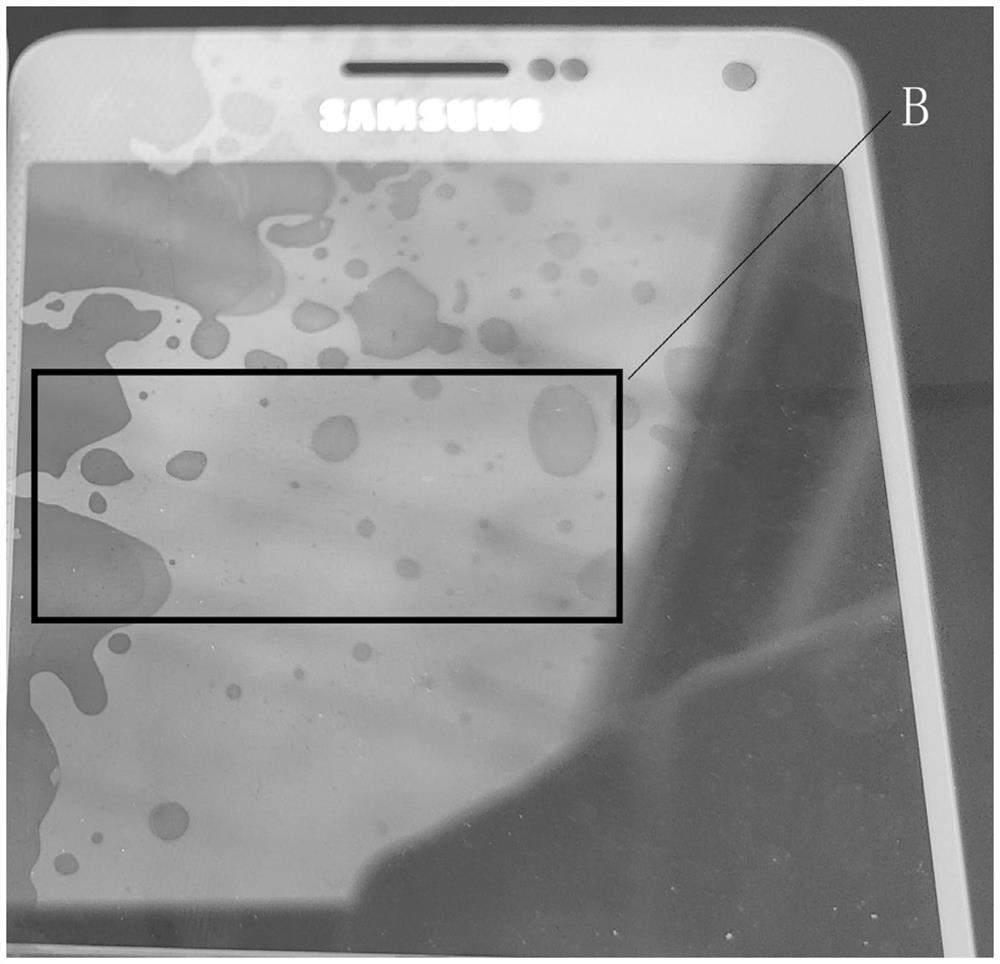

Image

Examples

Embodiment 1

[0033] The present embodiment provides a kind of water-based antistatic acrylic resin, comprising water-based acrylic resin coating, cross-linking curing agent and composite ionic liquid antistatic agent, the weight ratio of water-based acrylic resin coating, cross-linking curing agent and composite ionic liquid antistatic agent is 100: (0.5~2): (0.5~5);

[0034] Wherein, water-based acrylic resin paint comprises water-based acrylic resin, emulsifier, buffer and water, and the weight ratio of water-based acrylic resin, emulsifier, buffer and water is (30~60):(1~3):(0.5~5 ): (40~70);

[0035]Composite ionic liquid antistatic agent comprises 1-ethyl-3-methylimidazole ethyl sulfate, trihydroxyethylmethylamine methyl sulfate and tri-n-butylmethylammonium bis(trifluoromethanesulfonyl)imide, 1- The weight ratio of ethyl-3-methylimidazole ethyl sulfate, trihydroxyethylmethylamine methyl sulfate and tri-n-butylmethylammonium bis(trifluoromethanesulfonyl)imide is (80~90):(5 ~15): 5. ...

Embodiment 2

[0040] The present embodiment provides a kind of preparation method of waterborne antistatic acrylic resin, comprising:

[0041] Weigh (30~60):(1~3):(0.5~5):(40~70) weight ratio of water-based acrylic resin, emulsifier, buffer and water, fully stir and mix at room temperature to obtain water-based Acrylic resin paint; weigh (80~90):(5~15):5 weight ratio of 1-ethyl-3-methylimidazole ethyl sulfate, trihydroxyethylmethylamine methyl sulfate and tri-n-butyl methyl Ammonium bis(trifluoromethanesulfonyl)imide, fully stirred and mixed at room temperature to obtain a composite ionic liquid antistatic agent; weigh 100:(0.5~2):(0.5~5) water-based acrylic resin Coatings, cross-linking curing agents and composite ionic liquid antistatic agents. Under normal temperature conditions, add a cross-linking curing agent to the water-based acrylic resin coating, and then use a mechanical mixer to stir at a speed of 300-400rpm for 10-15min; Stir at a speed of 350-450 rpm for 10-15 minutes, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com