High-temperature raw ore blue glaze and preparation method thereof

A blue and glaze technology, which is applied in the field of high-temperature raw ore blue glaze and its preparation, can solve the problems of high difficulty in firing process control, low wear resistance of glaze, orange glaze, etc., to improve the color effect and glaze surface Good flatness and oily color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

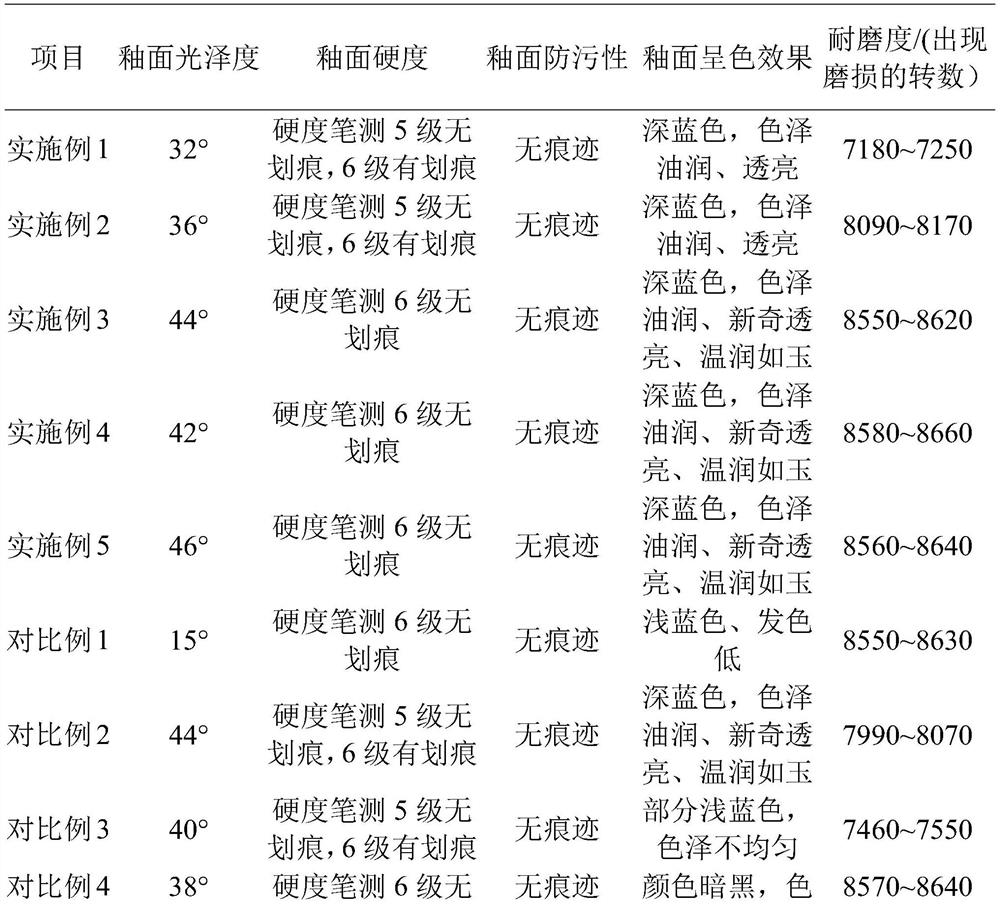

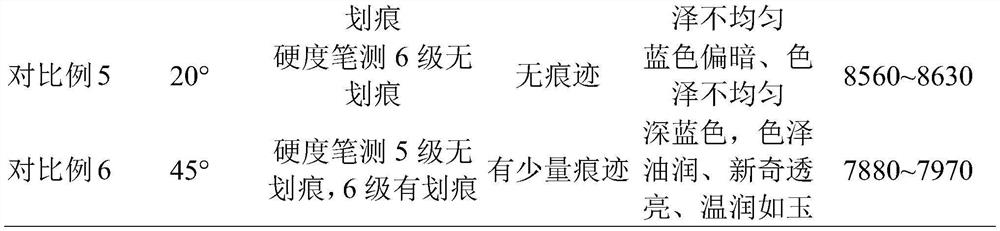

Examples

Embodiment 1

[0025] Embodiment 1 - a kind of high-temperature raw ore blue glaze, according to the ratio of parts by weight, including the following raw materials: 8 parts of peach gum, 20 parts of lapis lazuli, 10 parts of Yuhua stone, 25 parts of upper water stone, 2 parts of vermiculite, wear-resistant material 3 parts and 44 parts of water;

[0026] The wear-resistant material includes 12 parts of calcined white talc, 5 parts of potassium feldspar powder, and 3 parts of muscovite powder according to the ratio of parts by weight; the wear-resistant material is directly obtained by mixing the above raw materials, and the potassium feldspar powder The particle size is 10 μm, and the muscovite powder is 20 μm;

[0027] The above water stone is obtained by hot air drying at 100° C. after crushing to a particle size of 1.5 mm.

Embodiment 2

[0028] Embodiment 2 - a kind of high-temperature raw ore blue glaze, according to the ratio of parts by weight, including the following raw materials: 8 parts of peach gum, 20 parts of lapis lazuli, 10 parts of Yuhua stone, 25 parts of upper water stone, 2 parts of vermiculite, wear-resistant material 3 parts and 44 parts of water;

[0029] The wear-resistant material comprises 12 parts of calcined white talc, 5 parts of potassium feldspar micropowder, and 3 parts of muscovite micropowder according to the ratio in parts by weight; after mixing calcined white talc, potassium feldspar micropowder and muscovite micropowder in proportion, It is obtained by melting at 1520°C for 60 minutes, cooling, and crushing through a 60-mesh sieve; the particle size of the potassium feldspar powder is 10 μm, and the muscovite powder is 20 μm;

[0030] The above water stone is obtained by hot air drying at 100° C. after crushing to a particle size of 1.5 mm.

Embodiment 3

[0031] Embodiment 3 - a kind of high-temperature raw ore blue glaze, according to the ratio of parts by weight, including the following raw materials: 8 parts of peach gum, 20 parts of lapis lazuli, 10 parts of Yuhua stone, 25 parts of upper water stone, 2 parts of vermiculite, wear-resistant material 3 parts, 7 parts cordierite and 44 parts water;

[0032] The wear-resistant material includes 12 parts of calcined white talc, 5 parts of potassium feldspar micropowder, and 3 parts of muscovite micropowder according to the ratio of parts by weight. After mixing calcined white talc, potassium feldspar micropowder and muscovite micropowder in proportion, It is obtained by melting at 1520° C. for 60 minutes, cooling, and crushing through a 60-mesh sieve; the particle size of the potassium feldspar powder is 10 μm, and that of the muscovite powder is 20 μm.

[0033] The above water stone is obtained by hot air drying at 100° C. after crushing to a particle size of 1.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com