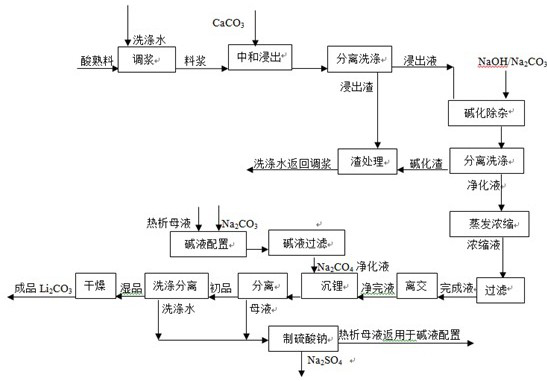

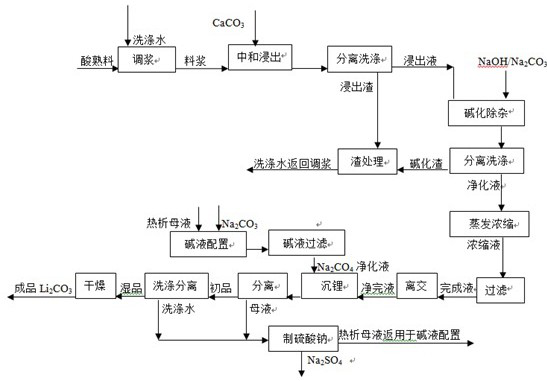

Preparation method of lithium carbonate

A lithium carbonate and lithium sulfate technology, applied in the preparation of sulfate/bisulfate, lithium carbonate;/acid carbonate, etc., can solve the problem of agglomeration and mutual wrapping, reducing sulfate content, complex chemical composition, etc. problem, to achieve the effect of improving conversion rate, increasing reaction area and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Add 1000ml of water into the mixing tank, and mix 1kg Li 2 Add acid clinker with O content of 4.62% and 500ml of water evenly, and continue pulping at 25°C for 25 minutes;

[0048](2) Put the slurry preparation prepared in step 1 into a neutralization tank, and after ultrasonic stirring for 20 minutes (ultrasonic frequency 28kHz), slowly add heavy calcium powder to adjust the pH value of the solution in the tank to 6, and leaching 15 with ultrasonic stirring at 30°C Minutes, after standing for 10 minutes, centrifuge and rinse to obtain leachate, leach slag collected in the slag storage tank;

[0049] (3) Put the leaching solution obtained in step 2 into an alkalization tank, heat up to 70°C while ultrasonically stirring, slowly add caustic soda to adjust the pH value to 10, and continue the reaction for 8 minutes, then add 18ml of carbonic acid with a concentration of 220g / L Sodium solution, continue to react at 70°C for 20 minutes after feeding, centrifuge and rin...

Embodiment 2

[0060] (1) According to the liquid-solid ratio of 3:1, step (4) in the embodiment 1 is centrifugally filtered in the washing water storage tank and 2000ml of washing water is added in the slurry mixing tank, and 1kg Li 2 Add the acid clinker with an O content of 4.62%, the remaining 960ml of filtered washing water and 40ml of supplementary water, and continue the slurry preparation at 35°C for 20 minutes;

[0061] (2) Put the slurry prepared in step 1 into a neutralization tank, and after ultrasonic stirring for 15 minutes, slowly add heavy calcium powder, and the rest are the same as step (2) of embodiment 1;

[0062] (3) the sodium carbonate solution that adds is configured by embodiment 1 step (7) gained thermal analysis mother liquor, all the other are with embodiment 1 step (3);

[0063] (4) Water is joined in the slag stirring tank by the liquid-solid ratio of 1.1:1, and all the other are with embodiment 1 step (4);

[0064] (5) Concentrate and filter and evaporate and ...

Embodiment 3

[0072] (1) Centrifugal filtration and washing water (1500ml) in the washing water storage tank of step (4) in Example 2 are added in the slurry mixing tank, and 1kg Li 2 The O content is 4.62% acid clinker and the remaining filtration and washing water (800ml) are evenly added (liquid-solid ratio 2.3:1), and the pulping is continued at 60°C for 25 minutes;

[0073] (2) Put the sizing liquid obtained in step (1) into a neutralization tank, and after ultrasonic stirring for 20 minutes, slowly add heavy calcium powder calcium carbonate to adjust the pH value of the solution in the tank to 7, and leaching with ultrasonic stirring at 60°C for 25 minutes, After standing for 20 minutes, centrifuge and rinse to obtain leachate, and leach slag is collected in the slag storage tank;

[0074] (3) Put the leaching solution obtained in step (2) into an alkalization tank, heat up to 90°C while ultrasonically stirring, add caustic soda to adjust the pH value to 11, and then continue to react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com