Machining method for cast cone ring block special-shaped mounting edge

A processing method and technology of a cone ring, applied in the aerospace field, can solve the problems affecting the processing quality and efficiency of parts, poor structural manufacturability, etc., and achieve the effects of improving processing efficiency, dimensional stability and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

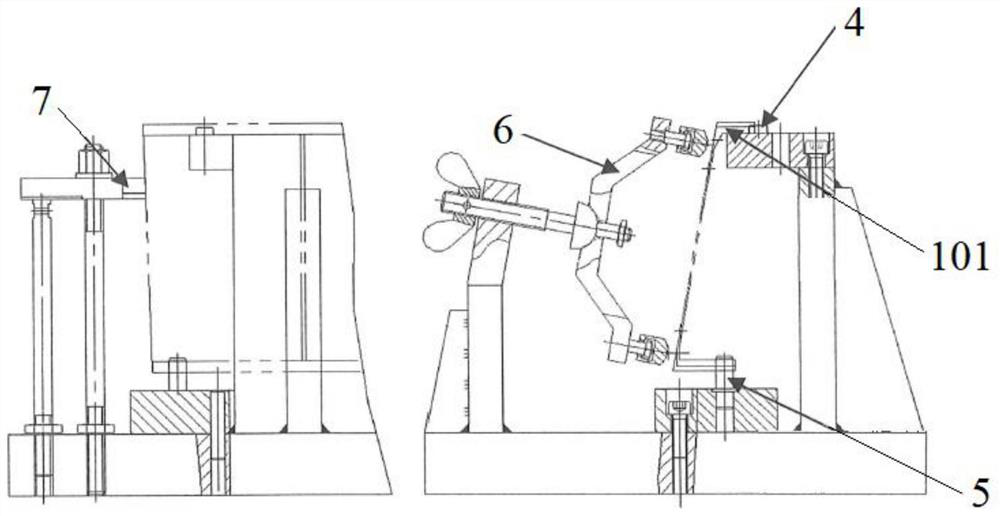

[0049] The purpose of this embodiment is to provide a processing method for casting the special-shaped mounting edge of the casting cone ring block, which is used to solve a series of problems affecting the processing quality and efficiency of the parts caused by the poor structural manufacturability of the casting cone ring block special-shaped mounting edge parts The problem.

[0050]This embodiment specifically provides a processing method for casting a special-shaped mounting edge of a cone ring block, which at least includes:

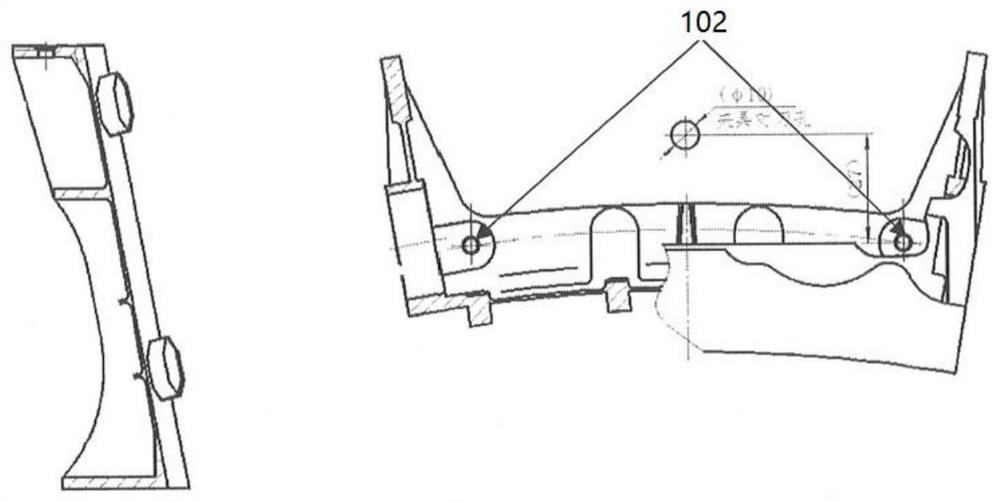

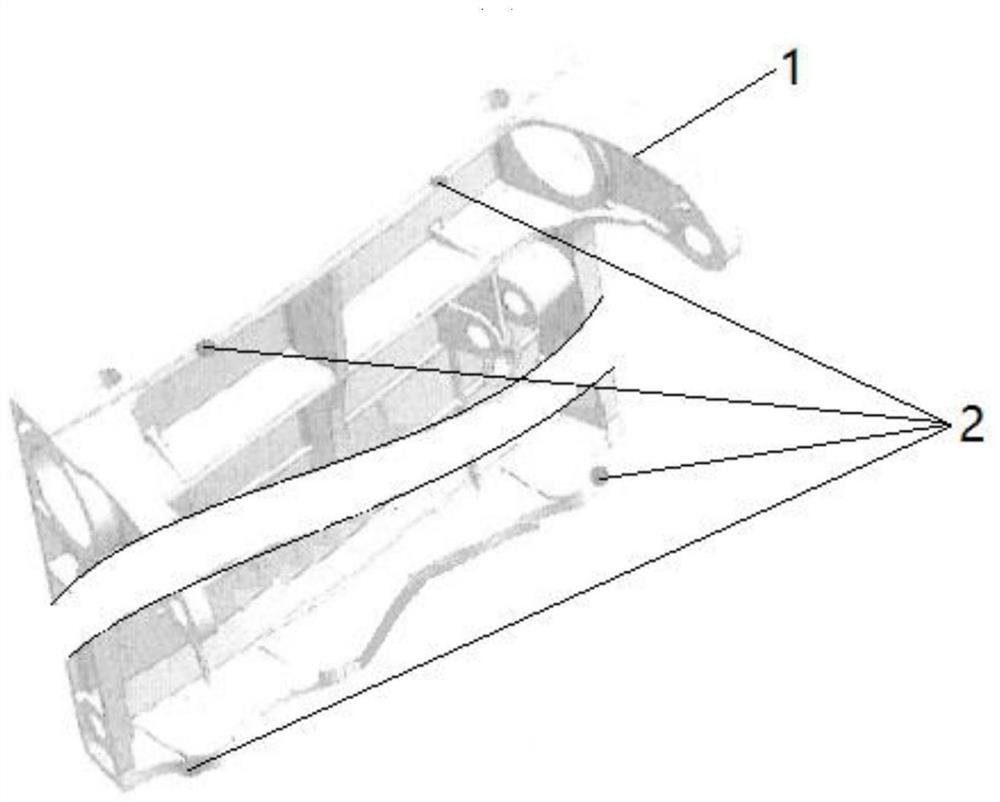

[0051] A. Rough datum planning: determine 4 rough datum points 2 at the inner side walls of the upper and lower ends of the casting blank 1.

[0052] In the prior art, the initial rough datum of the casting blank adopts three dimensional datum points on the cone surface. Although the coincidence of the design datum and the process datum is realized, the three datum points on the cone surface are affected by various factors such as small Factors su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com