Installation method for improving contact rigidity between piezoelectric element and conducting strips

A piezoelectric element and contact stiffness technology, which is applied in the installation field of improving the contact stiffness between the piezoelectric element and the conductive sheet, can solve the problems of crushing the piezoelectric element, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides an installation method for improving the contact stiffness between the piezoelectric element and the conductive sheet, including the following steps:

[0036] (1) A conductive sheet is respectively installed on the two electrode surfaces of the piezoelectric element;

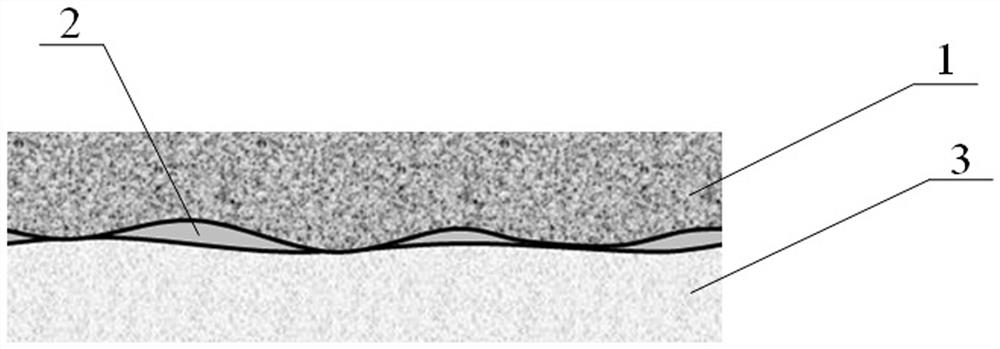

[0037] (2) A metal foil is arranged between the piezoelectric element and the conductive sheet;

[0038] (3) Apply a uniform pre-tightening force to the conductive sheets on both sides, so that the metal foil between the piezoelectric element and the conductive sheet is stretched and deformed, and the microscopic contact gap between the piezoelectric element and the conductive sheet is filled.

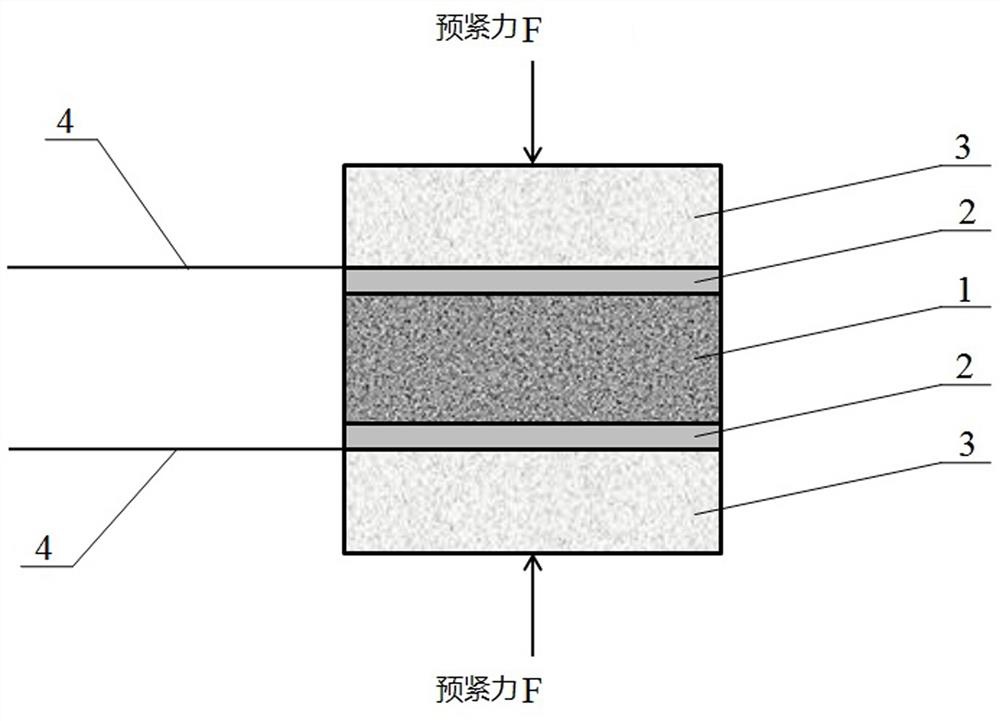

[0039] The specific installation structure after installation, such as figure 1 As shown, the conductive sheet 3, the metal foil 2, the piezoelectric element 1, the metal foil 2, and the conductive sheet 3 are sequentially stacked and installed. By applying the pre-tightening force F to ...

Embodiment 2

[0041] In this embodiment, on the basis of the above embodiments, the material of the conductive sheet is further limited, and the conductive sheet is made of conductive glass material. The conductive sheet made of conductive glass material has high hardness and very small roughness on the surface, thereby further improving the contact rigidity between the piezoelectric element and the conductive sheet. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0043] In this embodiment, on the basis of the above embodiments, the material of the conductive glass is further limited, and the material of the conductive glass is ITO conductive film glass. In order to ensure high rigidity and small roughness of the surface of the conductive sheet, the preferred conductive glass material here is ITO conductive film glass, and other conductive glass materials that can ensure high steel height and small roughness of the conductive sheet surface can also be selected. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com