Multiple-prismatic high speed entity ball bearing retainer

A cage, polygonal technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems affecting bearing noise and service life, unstable high-speed performance of the cage, and difficulty in maintaining the balance of the cage. The effect of reducing surface wear, improving high-speed running stability, and improving lubricating state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

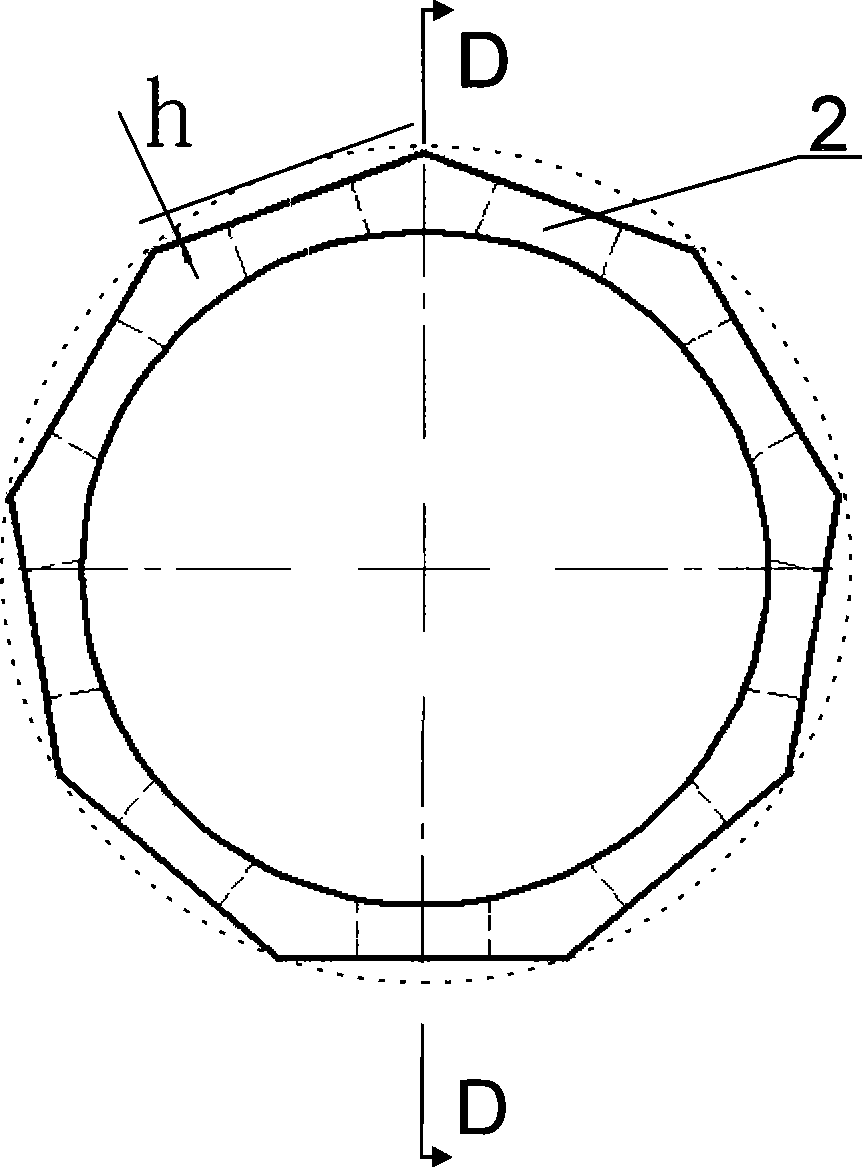

[0017] combine image 3 , 4 , the multi-prismatic high-speed solid ball bearing cage of the present invention is to make an outer diameter tangent line perpendicular to the center line on the center line of each pocket hole of the cage, and connect the intersection points of the outer diameter tangent lines of each center line to form a multiple Prismatic, the thickness at the intersection of all tangents is increased, so that the contact stiffness is also increased accordingly, ensuring the overall rigidity of the polygonal cage 2; due to the polygonal structure of the cage, it is compatible with the circular The contact of the guide rib of the bearing ring is two-point contact in a stable contact state. On the one hand, the two-point contact can significantly enhance the support stability of the cage and improve the high-speed running stability of the cage. The contact stress of the contact point reduces the friction and wear of the cage, and at the same time, the tangent s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com