Circular vibrating screen lubricated by thin oil

A circular vibrating screen, thin oil lubrication technology, applied in the direction of lubricating parts, engine lubrication, lubricating oil control valve, etc. Easy maintenance, good lubrication and stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

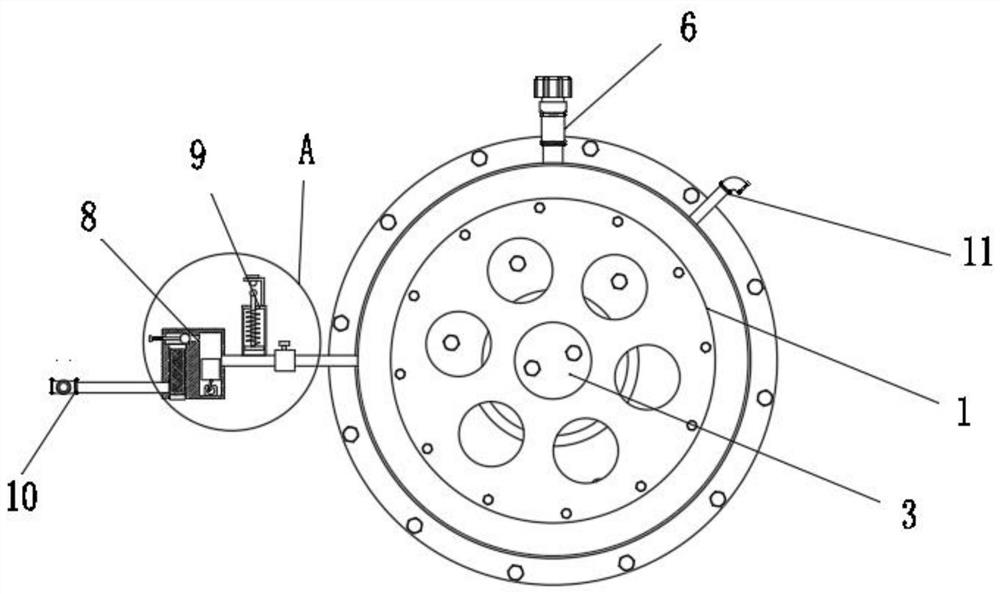

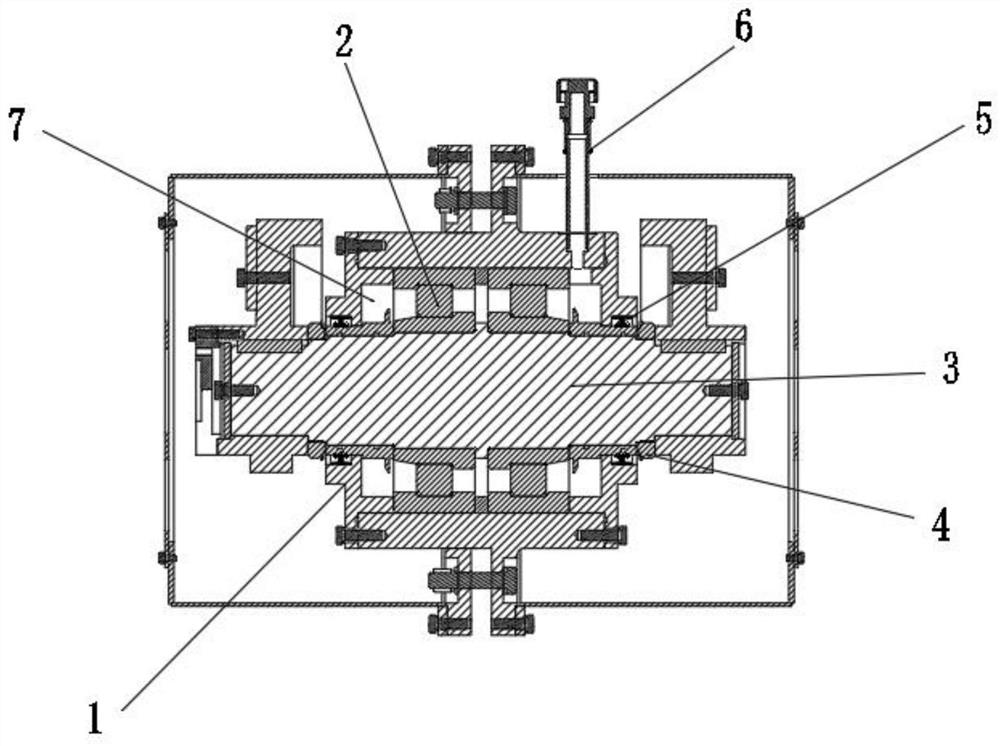

[0027] like Figure 1 to Figure 4 As shown, a thin oil lubricated circular vibrating screen according to the present invention includes an installation main body 1, a bearing 2, a main shaft 3, a round nut 4, a lip seal 5, an exhaust pipe 6, a lubricating inner cavity 7, and a Pressure component 8, release component 9, oil discharge pipe 10 and oil inlet pipe 11; bearing 2 is installed inside the installation body 1, the main shaft 3 is installed inside the installation main body 1, the main shaft 3 runs through the inside of the bearing 2, the installation body 1 and the main shaft 3 The splicing port is filled with a lip seal 5, the two ends of the installation body 1 are sealed with round nuts 4, a lubricating inner cavity 7 is formed between the installation body 1 and the main shaft 3, and oil drain pipes 10 are respectively installed on the installation body 1 And the oil inlet pipe 11, the oil discharge pipe 10 is provided with a pressurizing assembly 8 and a release as...

Embodiment approach

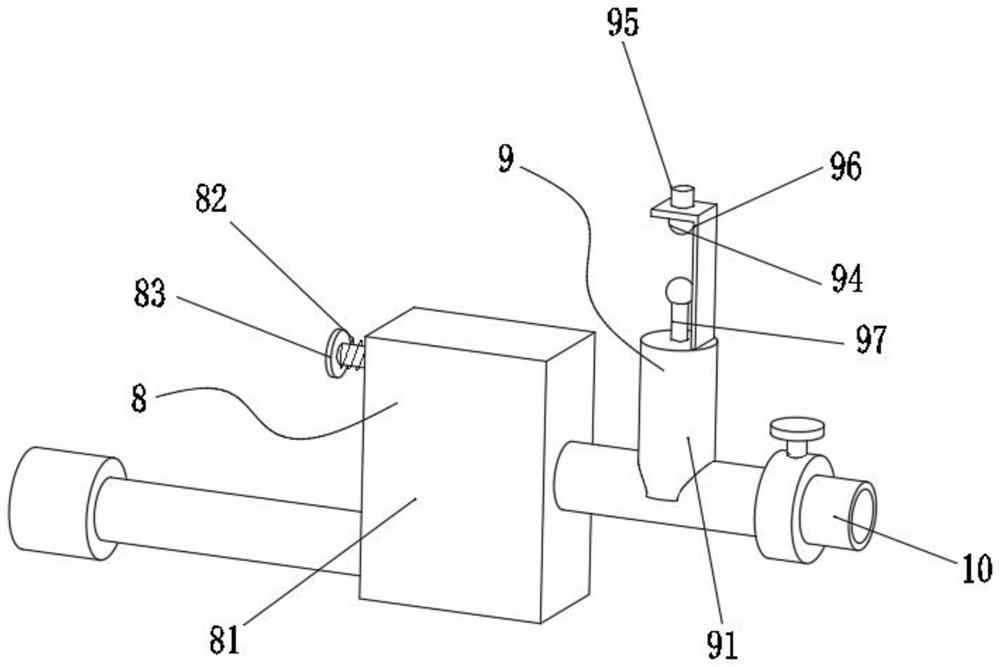

[0028] As an embodiment of the present invention, the pressurizing assembly 8 includes a pressurizing box 81, a first spring 82, a squeeze rod 83, a blocking ball 84, a filter chamber 85, a filter core 86, a stamping motor 87, a pull rod 88, a rotating Disc 89, piston cylinder 810 and stamping chamber 811, filter chamber 85 and stamping chamber 811 are arranged inside pressurized box 81, piston cylinder 810 is arranged inside stamping chamber 811, stamping motor is fixed on the bottom cavity wall of stamping chamber 811 87. A rotary disc 89 is installed on the rotating shaft of the stamping motor 87, and a connecting seat is installed at the bottom end of the piston cylinder 810. The bottom end of the pull rod 88 is mounted on the eccentric position of the end face of the rotary disc 89 through a pin shaft, and the top end of the pull rod 88 passes through The pin shaft is matched and installed in the connecting seat. The bottom of the filter chamber 85 is a hollow structure. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com