Special fertilizer for asparagus in coastal saline-alkali land and preparation method of special fertilizer

A technology of saline-alkali soil and special fertilizer, applied in the field of plant bioengineering, can solve the problems of slow nutrient absorption and accumulation of asparagus, short fertilizer efficiency of ordinary compound fertilizer, low organic matter content, etc. The effect of good sex and reasonable nutritional distribution ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

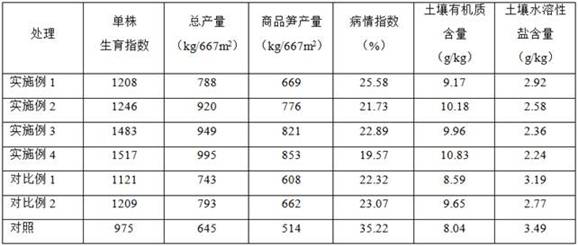

Examples

Embodiment 1

[0037] A special fertilizer for asparagus in coastal saline-alkali land, comprising: 300 parts by weight of urea, 200 parts of superphosphate, 150 parts of potassium sulfate, 10 parts of magnesium sulfate, 8 parts of ferrous sulfate, 8 parts of zinc sulfate, humic acid 80 parts, 1 part of chitosan oligosaccharide, 10 parts of montmorillonite powder, 250 parts of dried livestock manure after fermentation and deodorization, 2 parts of NAM additive.

[0038] The urea contains 46% nitrogen;

[0039] Described superphosphate contains phosphorus pentoxide 16%, calcium oxide 12%;

[0040] The potassium sulfate contains 50% potassium oxide.

[0041] A preparation method of special fertilizer for asparagus in coastal saline-alkali land, specifically:

[0042] 1. Pulverize all raw materials separately;

[0043]2. Weigh 1 / 4 urea, 1 / 2 potassium sulfate, 1 / 4 superphosphate, 1 / 3 magnesium sulfate, 1 / 3 zinc sulfate, 1 / 3 ferrous sulfate and put them into the mixer and stir for 5 After mix...

Embodiment 2

[0047] A special fertilizer for asparagus in coastal saline-alkali land, comprising: 450 parts by weight of urea, 350 parts of superphosphate, 250 parts of potassium sulfate, 20 parts of magnesium sulfate, 15 parts of ferrous sulfate, 15 parts of zinc sulfate, humic acid 150 parts, 3 parts of chitosan oligosaccharide, 25 parts of montmorillonite powder, 400 parts of dried livestock manure after fermentation and deodorization, 3.5 parts of NAM additive.

[0048] The urea contains 46% nitrogen;

[0049] Described superphosphate contains phosphorus pentoxide 16%, calcium oxide 12%;

[0050] The potassium sulfate contains 50% potassium oxide.

[0051] A preparation method of special fertilizer for asparagus in coastal saline-alkali land, specifically:

[0052] 1. Pulverize all raw materials separately;

[0053] 2. Weigh 1 / 4 urea, 1 / 2 potassium sulfate, 1 / 4 superphosphate, 1 / 3 magnesium sulfate, 1 / 3 zinc sulfate, and 1 / 3 ferrous sulfate respectively and put them into the mixer t...

Embodiment 3

[0057] A special fertilizer for asparagus in coastal saline-alkali land, in parts by weight, 300 parts of urea, 200 parts of superphosphate, 150 parts of potassium sulfate, 10 parts of magnesium sulfate, 8 parts of ferrous sulfate, 8 parts of zinc sulfate, modified humic acid 80 parts, 1 part of chitosan oligosaccharide, 10 parts of loaded fertilizer, 250 parts of dried livestock and poultry manure after fermentation and deodorization, 2 parts of NAM additive.

[0058] The preparation method of the modified humic acid is: mix humic acid, sodium humate and potassium humate evenly according to the mass ratio of 10:3:1 to obtain a mixture, dissolve the mixture in a mixed solvent, and control the mixture The mass ratio to the mixed solvent is 1:4, then the temperature of the mixed solvent is controlled to 50°C, and the stirring is started, and the stirring speed is controlled to be 200rpm. After stirring for 30min, guar gum and white fungus polysaccharide are added, and the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com