Printing quality detection and analysis system based on deep learning

A deep learning and analysis system technology, applied in the field of deep learning, can solve the problems of not being able to improve the process or equipment, unable to accurately locate defective process links, unable to formulate and implement improvement measures, etc., to achieve the direction of process improvement, Accurate quality report and comprehensive quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

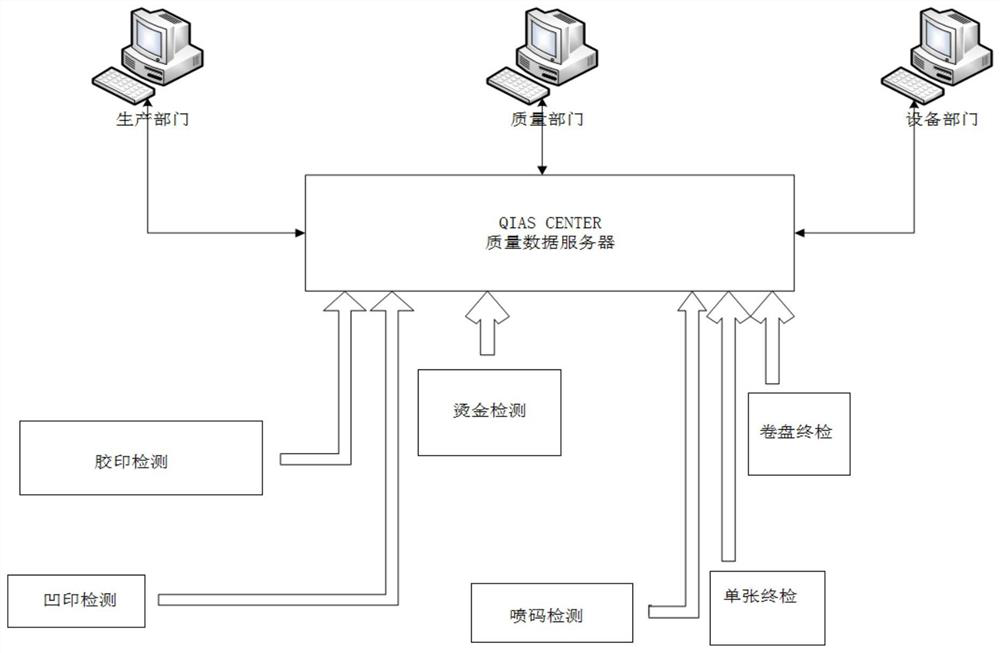

[0041] Such as Figure 1-Figure 8 A printing quality inspection and analysis system based on deep learning is shown. The overall system architecture includes a client-side independent defect image data collection and sending module, a client-side and server-side communication module, a server-side defect image data receiving and storage module, The server-side defect image deep learning classification module, the server-side deep learning training module and the server-side report display module.

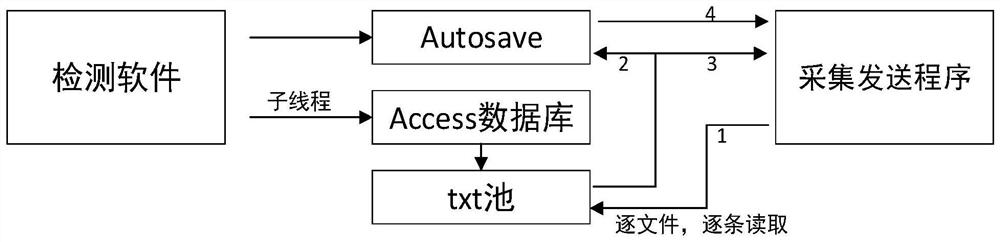

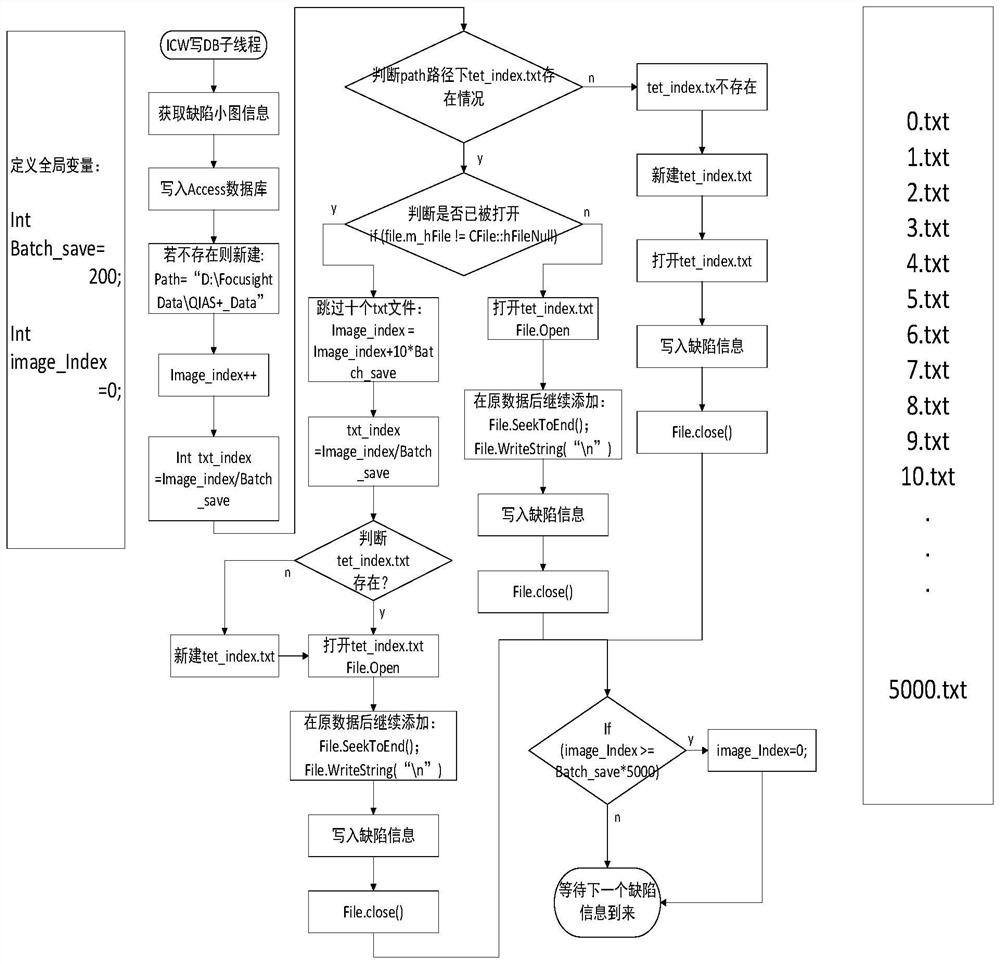

[0042] The client-side independent defect data collection and sending module adopts the fast recording and retrieval function o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com