Bridge deck slab capable of being used for steel-UHPC composite beam bridge, steel channel beam, beam bridge and construction method thereof

A bridge deck and steel channel beam technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of poor crack resistance of concrete bridge decks, heavy bridge structure, low span, etc., to improve the crack resistance of pier tops, The effect of improved leaping ability and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

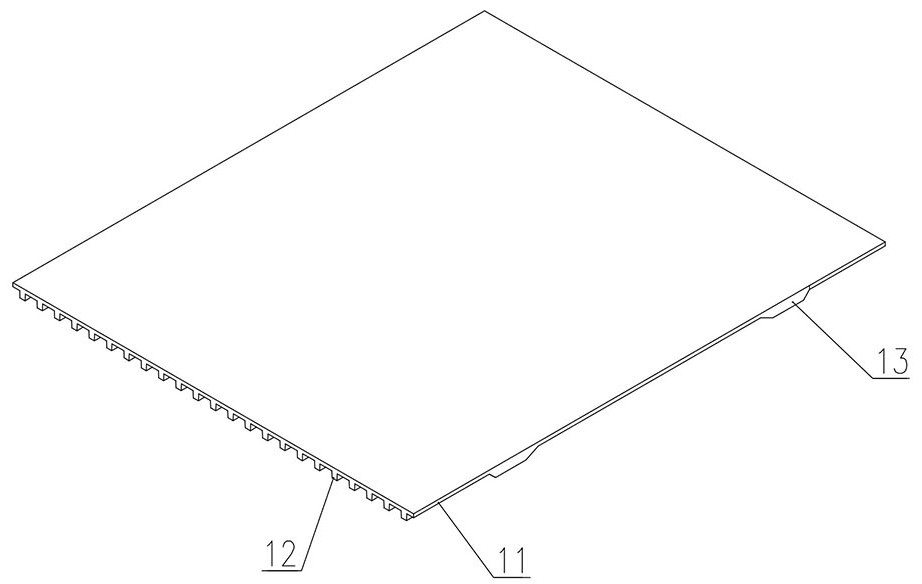

[0051] A unidirectional rib UHPC deck that can be used in steel-UHPC composite girder bridges.

[0052] Such as Figure 1-5 As shown, the unidirectional rib UHPC bridge deck 1 includes a bridge deck body 11, a UHPC transverse rib 12, and a longitudinally thickened portion 13 fixedly connected to the lower steel channel girder 2 of the steel-UHPC composite girder bridge.

[0053] UHPC transverse ribs 12 are arranged under the bridge deck body 11, and the spacing S between two adjacent UHPC transverse ribs 12 is 600mm. The arrangement spacing S is the spacing between the vertical planes of the UHPC transverse ribs 12 along the transverse bridge direction; the bottom surface of the UHPC transverse ribs 12 is provided with steel strips 121, and the thickness of the steel strips 121 is 8 mm. The steel slats 121 are fixed with pegs 122 embedded in the UHPC transverse ribs 12, and the pegs 122 extend upwards from the steel slats 121 into the bridge deck body 11, and there is no brid...

Embodiment 2

[0056] A steel channel girder that can be used in steel-UHPC composite girder bridges.

[0057] Such as Figure 6 and 7 As shown, the steel channel beam 2 is a U-shaped channel beam. The steel channel beam 2 includes a bottom plate 21, a web 22 connected to both sides of the bottom plate 21 and a flange plate 25. Both the bottom plate 21 and the web 22 are provided with longitudinal bridges. Stiffener 23, the top of the web 22 is fixed with the flange plate 25 fixedly connected with the one-way rib UHPC bridge deck 1 of embodiment 1, and the flange plate 25 passes through the shear key 3 (this embodiment adopts the peg 122 ) is fixedly connected to the unidirectional rib UHPC bridge deck 1. The web 22 is designed to be inclined, and the surface of the web 22 forms an obtuse angle with the bottom plate 21 .

[0058] The bottom plate 21 and the web 22 of the steel channel girder 2 are also provided with transverse bridge stiffeners 24, which are arranged orthogonally to the l...

Embodiment 3

[0061] A steel channel girder that can be used in steel-UHPC composite girder bridges.

[0062] Such as Figure 8 and 9 As shown, the steel channel beam 2 is a U-shaped channel beam. The steel channel beam 2 includes a bottom plate 21, a web 22 connected to both sides of the bottom plate 21 and a flange plate 25. Both the bottom plate 21 and the web 22 are provided with longitudinal bridges. Stiffener 23, the top of the web 22 is fixed with the flange plate 25 fixedly connected with the one-way rib UHPC bridge deck 1 of embodiment 1, and the flange plate 25 passes through the shear key 3 (this embodiment adopts the peg 122 ) is fixedly connected to the unidirectional rib UHPC bridge deck 1. The web 22 is designed to be inclined, and the surface of the web 22 forms an obtuse angle with the bottom plate 21 .

[0063] The bottom plate 21 and the web 22 of the steel channel girder 2 are also provided with transverse bridge stiffeners 24, which are arranged orthogonally to the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com