Steel pipe-reinforced concrete laminated framework structural system

A technology of reinforced concrete and frame structure, applied in the direction of structural elements, long-strip structural components for load-bearing, building components, etc. performance, the effect of reducing the amount of concrete and reducing the amount of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

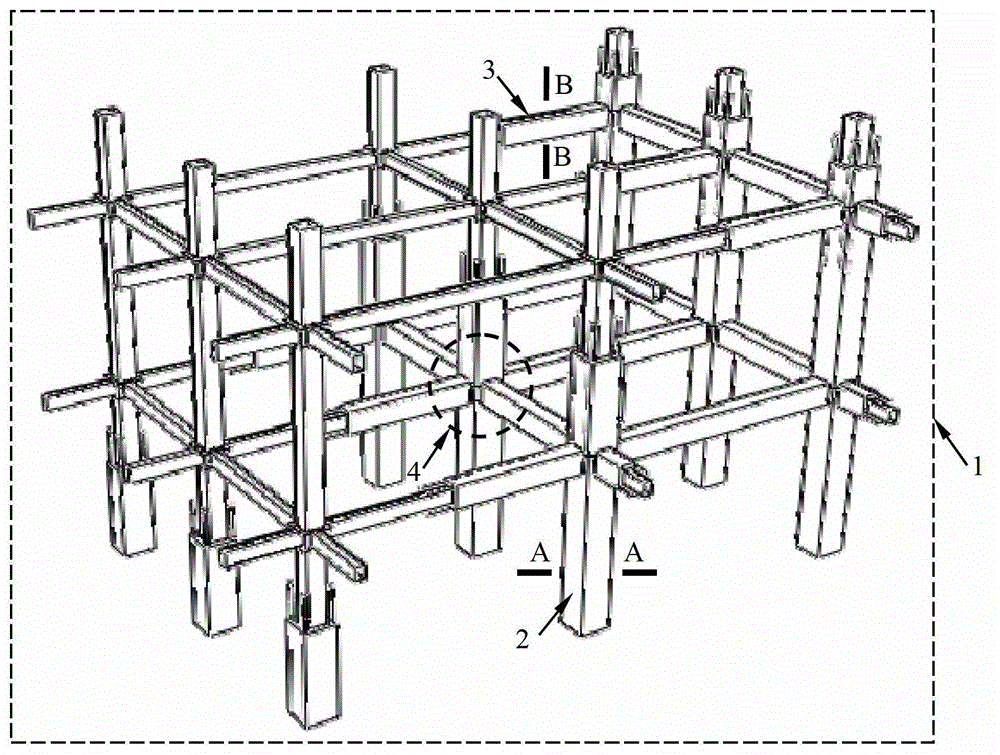

[0026] The present invention provides a steel pipe-reinforced concrete composite frame structure system. The structure and specific implementation methods of the present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

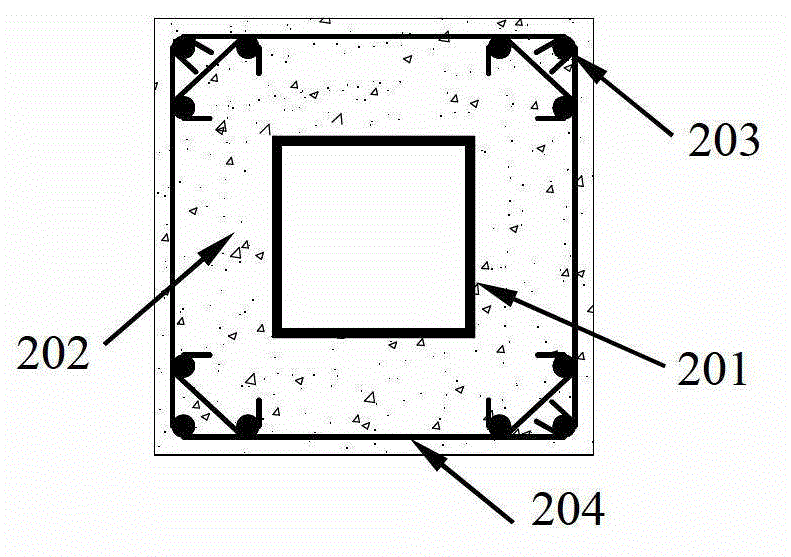

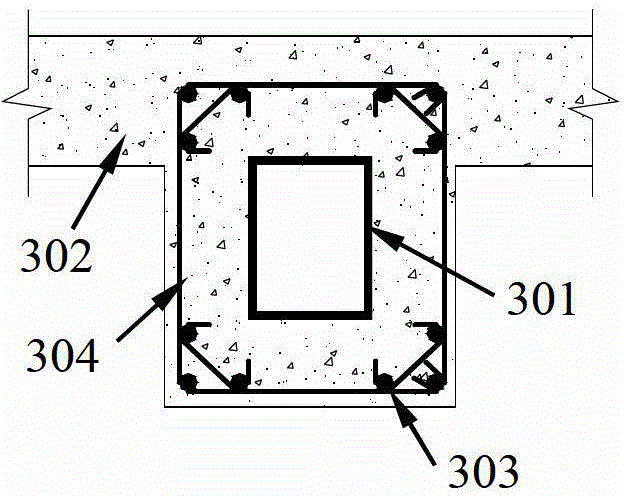

[0027] The purpose of the present invention is achieved through the following technical solutions: a steel pipe-reinforced concrete composite frame structure system 1 is composed of frame columns 2 , frame beams 3 and nodes 4 . The beam and column sections of the structural system 1 all adopt the combined structure of inner hollow steel pipe and outer reinforced concrete. In the frame column 2 described above, a column hollow steel pipe 201 is used inside, and column longitudinal reinforcement 203 and column stirrup 204 are arranged outside the steel pipe, and column concrete 202 is poured. In the frame beam 3 , hollow steel pipes 301 are used inside, longitudinal bars 303 and stirrups 304 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com