Economical aging-resistant high-strain precipitation strengthened pipeline steel and production method thereof

A precipitation strengthening and production method technology, applied in metal rolling, temperature control, etc., to reduce the impact of toughness, improve economic efficiency, and good economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

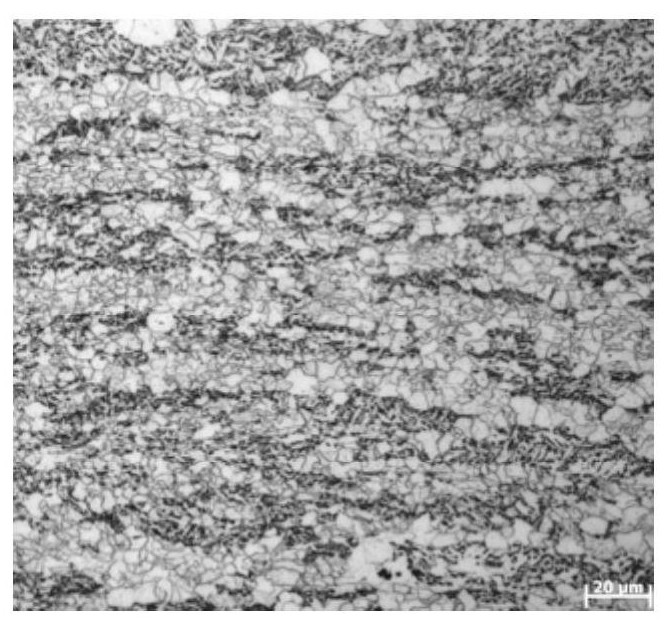

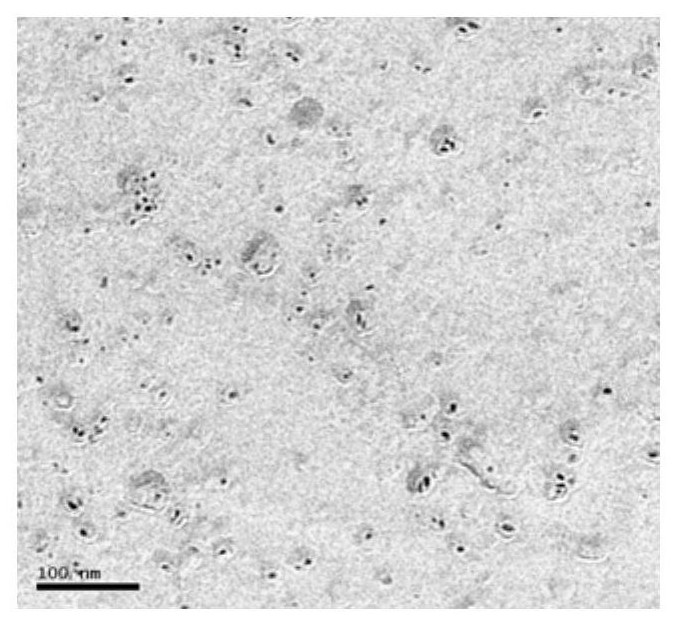

Image

Examples

Embodiment Construction

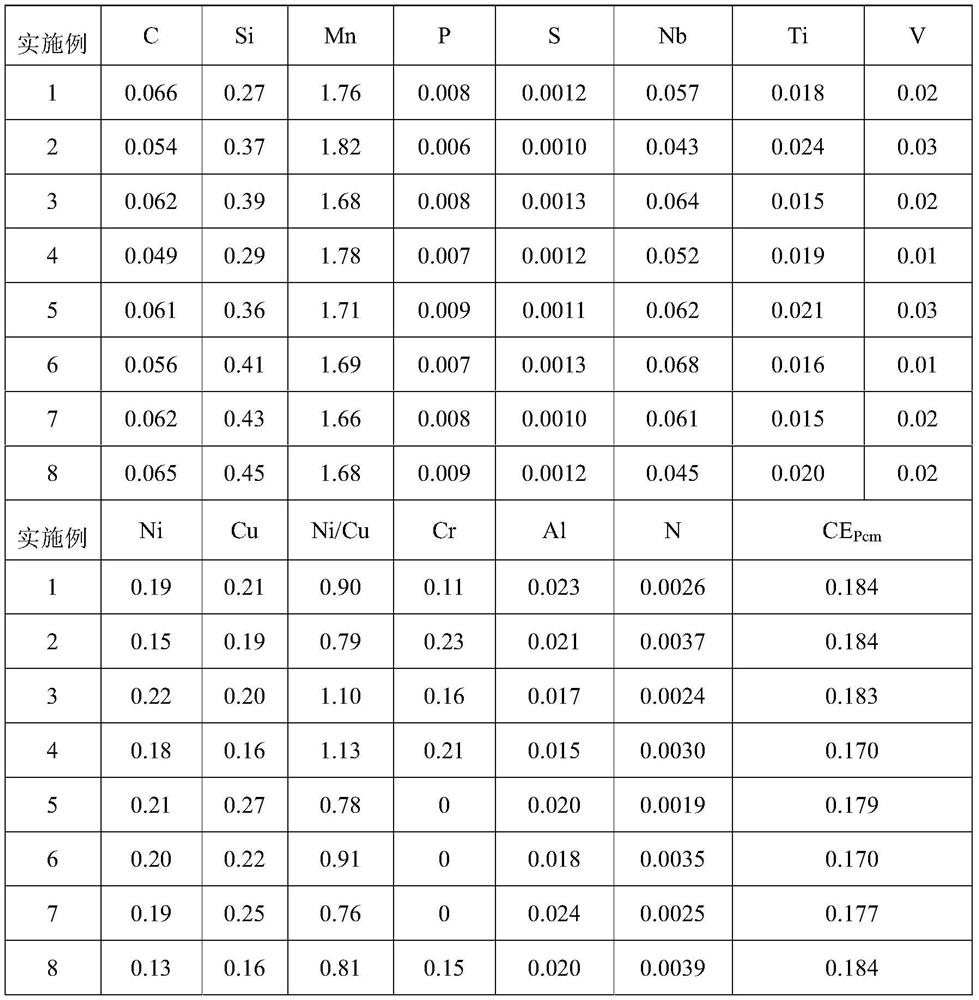

[0045] Below by embodiment the present invention will be further described.

[0046] In the embodiment of the present invention, smelting, continuous casting, rolling and cooling are carried out according to the component distribution ratio of the technical solution.

[0047] Smelting: When tapping the converter, the tapping temperature is ≤1640°C, C≤0.045%, the slag is blocked and the steel is tapped, and lime and fluorite topping slag are added according to the ratio of 4 / 1 to 5 / 1 during the tapping process; RH vacuum treatment time during the refining process ≥10min;

[0048] Continuous casting: during the continuous casting process, the pouring superheat of the continuous casting slab is 10-30°C, and the casting speed of the continuous casting slab is 0.8-1.2m / min;

[0049] Heating: The continuous casting slab adopts multi-stage heating of preheating section, heating section I, heating section II, and soaking section. The temperature of the soaking section is 1170-1200°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com