An intelligent cloud spray dust suppression system and method for a train unloading depot

A cloud and train technology, applied in separation methods, chemical instruments and methods, loading/unloading, etc., can solve the problems of low degree of automation, low dust removal efficiency, and inability to flexibly adjust the dust point, so as to reduce the number of operating positions and improve the control efficiency. The effect of dust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

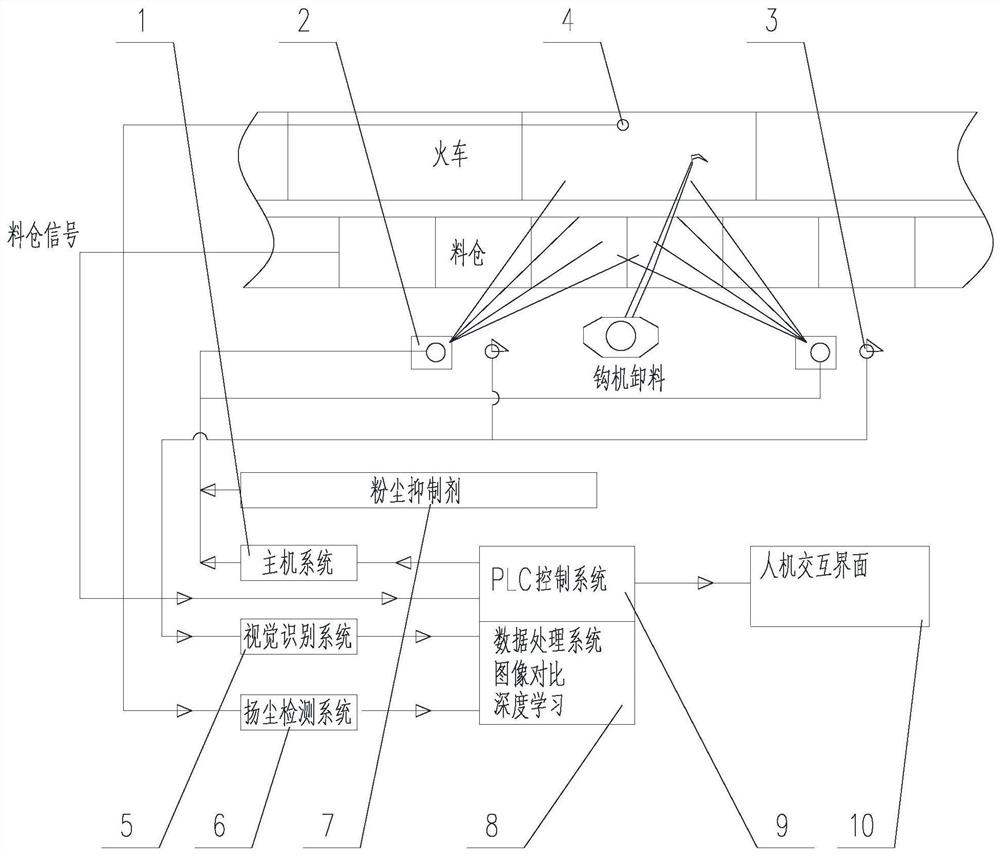

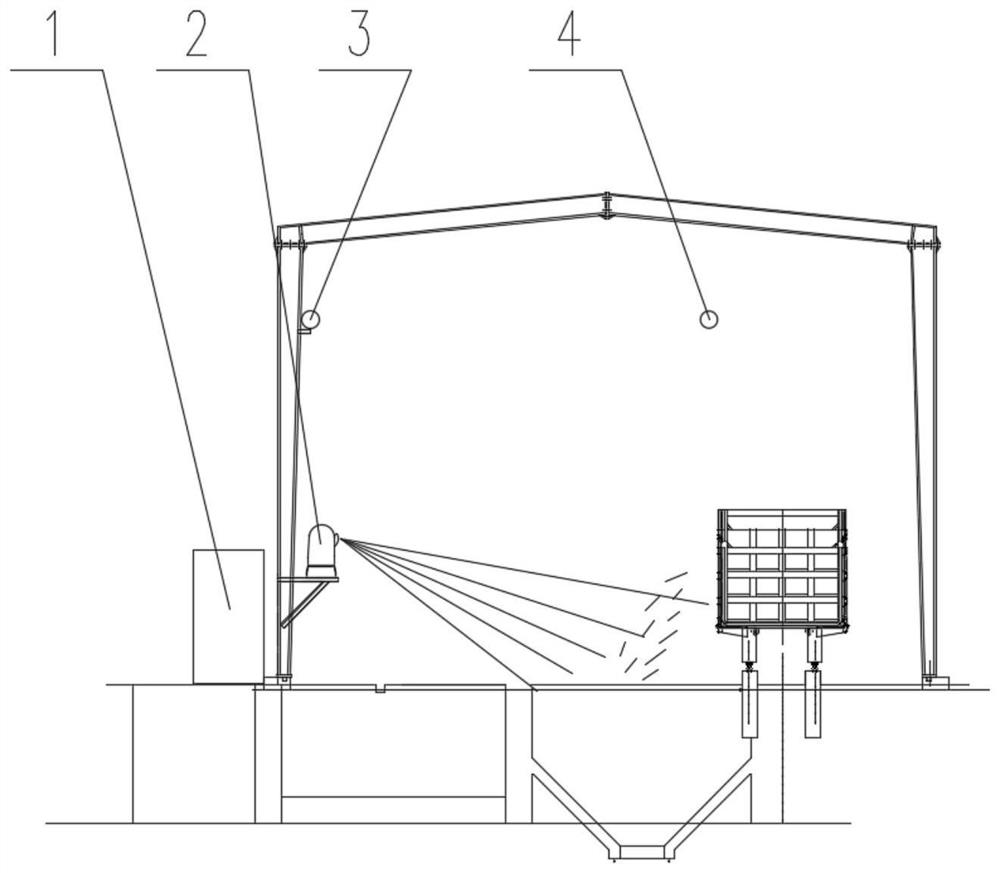

[0040] like figure 1 and figure 2 As shown, the present invention provides an intelligent cloud spray dust suppression system for a train unloading warehouse, including:

[0041] Cloud sprayer 2, used to spray clouds with fog particles ≤ 10μm to capture and suppress dust;

[0042] The host system 1 is used to supply air and water to the cloud sprayer 2;

[0043] At least one eagle-eye / frog-eye monitoring unit 3 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com