Intelligent cloud and mist spraying dust suppression system for train unloading warehouse and method

A cloud and train technology, applied in separation methods, chemical instruments and methods, loading/unloading, etc., can solve problems such as low degree of automation, low dust removal efficiency, and inability to flexibly adjust dust outlet points, so as to reduce operating positions and improve suppression The effect of dust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

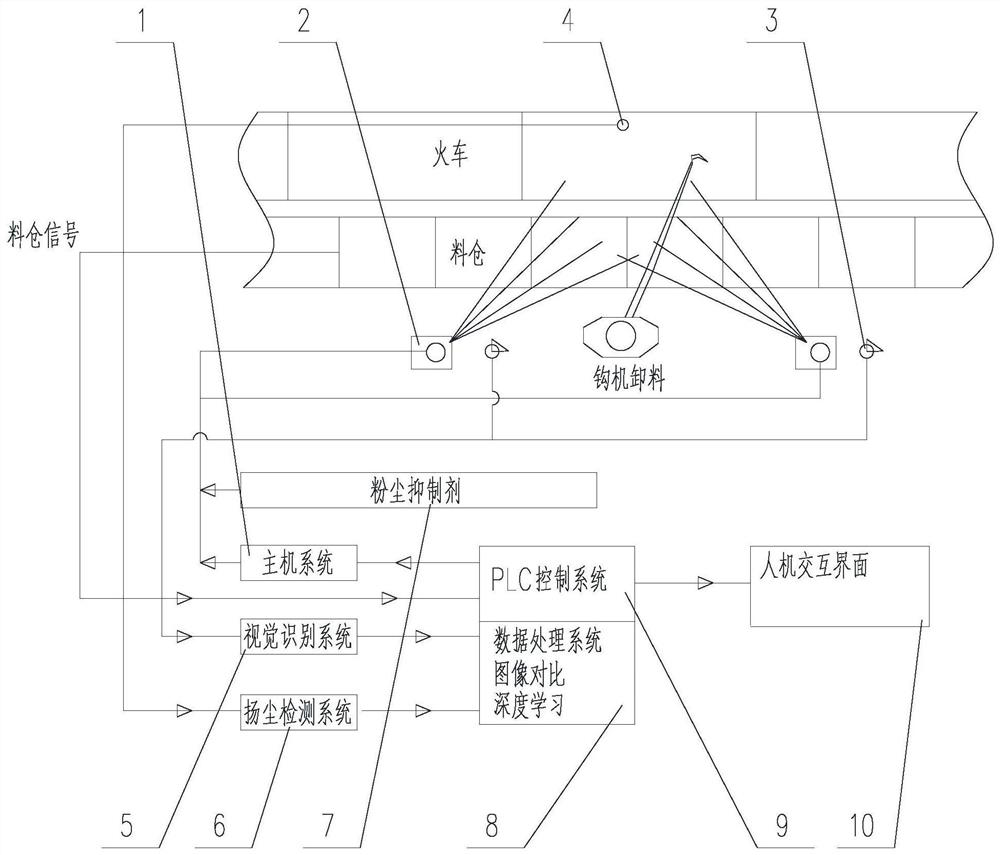

[0040] like figure 1 and figure 2 As shown, the present invention provides a smart cloud spray inhibition system of a train unloading library, including:

[0041] Cloud spray instrument 2 for spraying the mist of the haze ≤ 10 μm to capture and inhibit dust;

[0042] Host system 1 for supplying gas and water supply to the cloud sprayer 2;

[0043] At least one eagle eye / frog eye monitoring unit 3 is disposed on the unloading side of the train along the railway direction, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com