Method for monitoring separation and purification process of etimicin hydrolysate

A technology for separation and purification, etimicin, which is applied in material separation, analysis materials, measuring devices, etc., can solve the problems of poor reproducibility, poor linear relationship between concentration and peak area, and difficulty in continuity, and the method is simple and convenient. Feasible, specific, and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

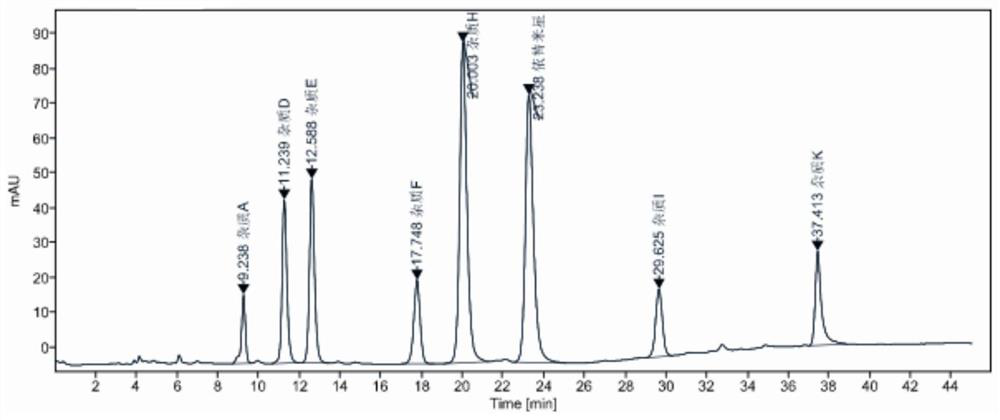

[0028] In this embodiment, the hydrolyzate of etimicin and the eluent at any stage were sampled and then detected by HPLC-post-column derivatization method.

[0029] Chromatographic column: Octadecylsilane bonded silica gel filled chromatographic column, particle size 2μm, column specification 100×2.0mm.

[0030] The mobile phase is divided into an organic phase and an aqueous phase, the organic phase is methanol, the aqueous phase is 0.05M trifluoroacetic acid, and potassium hydroxide is used to adjust the pH range to 2.0-3.5. The volume ratio of the organic phase to the aqueous phase is 45:55; the flow rate is 0.5mL / min.

[0031] The injection volume was 10 μL.

[0032] Derivatization reagent: Weigh 10g of boric acid, 5g of potassium hydroxide, add 800mL of water to dissolve; weigh 200mg of o-phthalaldehyde, dissolve with 10mL of methanol, add o-phthalaldehyde solution to boric acid buffer solution, add water to dilute to 1L, and then add Thioethanol 0.5-2.0mL, mix well an...

Embodiment 2)

[0038] The rest of the method for monitoring the separation and purification process of the etimicin hydrolyzate of the present embodiment are the same as in Example 1, except that:

[0039] Chromatographic column: Octadecylsilane bonded silica-filled chromatographic column with a particle size of 10 μm and a column specification of 300×8.0mm.

[0040] The mobile phase is divided into an organic phase and an aqueous phase, the organic phase is methanol, the aqueous phase is 0.3M trifluoroacetic acid, and potassium hydroxide is used to adjust the pH range to 3.0-3.5. The volume ratio of the organic phase to the aqueous phase is 50:50; the flow rate is 1.2mL / min.

[0041] The injection volume was 20 μL.

[0042] The derivatization conditions were as follows: the flow rate was 1.0 mL / min, and the derivatization reaction temperature was 70°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com