TiO2 reflective electrochromic film and preparation method thereof

An electrochromic and reflective technology, applied in the direction of electrolytic coating, electrophoretic coating, titanium oxide/hydroxide, etc., can solve the problem of low optical contrast of electrochromic film, limited application in electrochromic field, unfavorable ion migration, etc. problem, to achieve the effect of improving the kinetic activity of the electrochemical reaction, facilitating large-scale production, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Put the FTO conductive glass in acetone, absolute ethanol, and deionized water for ultrasonic cleaning, and dry it for later use.

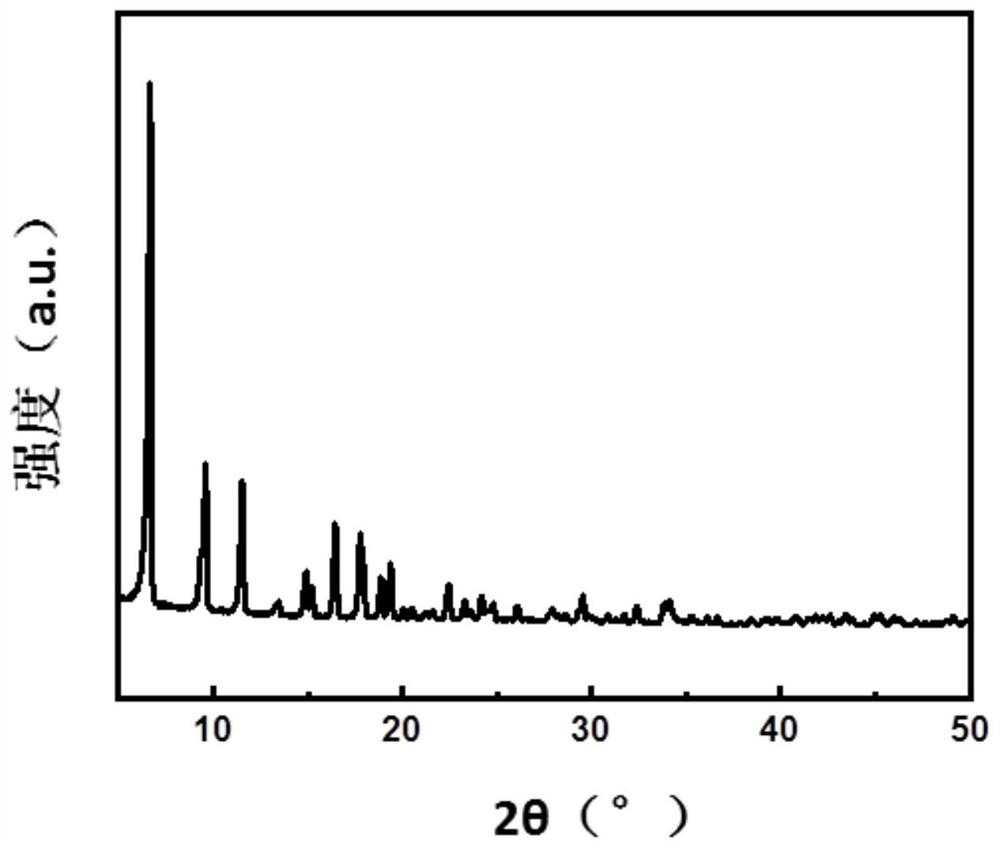

[0041] (1) Mix 27mL of N,N-dimethylformamide (DMF) with 3mL of methanol, add 1.65g of terephthalic acid with magnetic stirring to fully dissolve, then add 1.8mL of tetrabutyl titanate (relative density is 0.996 g / cm 3 ) to continue stirring evenly to obtain a mixed solution, transfer the above mixed solution to a polytetrafluoroethylene-lined reactor, then put the reactor into a blast drying oven at 160°C for solvothermal reaction for 24 hours, after the reaction is completed, The solution in the reaction kettle was collected by centrifugation at 8000r / min, then washed with DMF and methanol for 3 times, and dried to obtain Ti-MOF particles.

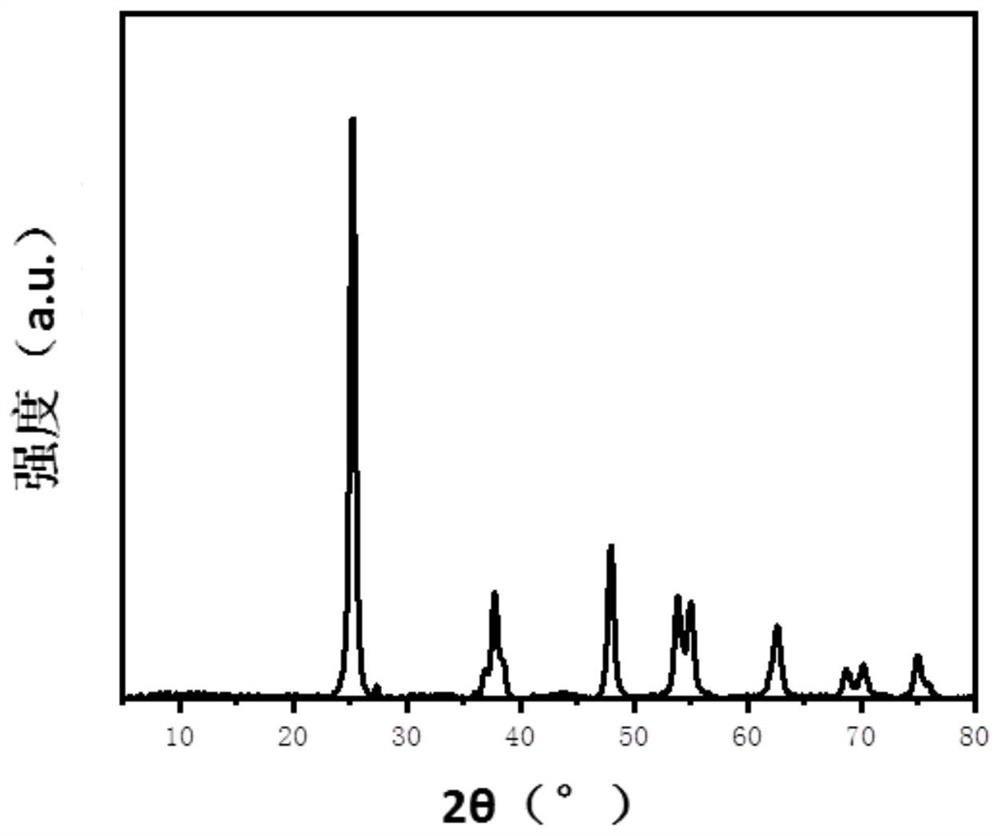

[0042] (2) Calcinate Ti-MOF particles at 450°C for 4h, wash and filter, then dry at 60°C for 12h to obtain TiO 2 Particles; take 40mg of the above TiO 2 Particles were ultrasonically dispersed in 80...

Embodiment 2

[0046] Put the FTO conductive glass in acetone, absolute ethanol, and deionized water for ultrasonic cleaning, and dry it for later use.

[0047] (1) Mix 27mL of N,N-dimethylformamide with 3mL of methanol, add 1.65g of terephthalic acid with magnetic stirring to fully dissolve, then add 1.8mL of tetrabutyl titanate (relative density is 0.996g / cm 3 ) to continue stirring evenly to obtain a mixed solution, transfer the above mixed solution to a polytetrafluoroethylene-lined reactor, then put the reactor into a blast drying oven at 160°C for solvothermal reaction for 24 hours, after the reaction is completed, The solution in the reactor was collected by centrifugation at 8000r / min, then washed with DMF and methanol three times, and dried to obtain Ti-MOF particles.

[0048] (2) Calcinate Ti-MOF particles at 500°C for 4h, wash and filter, then dry at 60°C for 12h to obtain TiO 2 Granules; take 32mg of the above TiO 2 Particles were ultrasonically dispersed in 80mL acetone, and T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com