Preparation method of ceramic membrane with antibacterial function based on magnesium alloy

A technology of ceramic film and magnesium alloy, which is applied in anodic oxidation and other directions, can solve the problems of silver ion failure, affecting antibacterial durability, and poor antibacterial effect, and achieve high antibacterial, enhanced durability, and enhanced antibacterial effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A preparation of a ceramic film with antibacterial function based on magnesium alloy, denoted as ZA0, the specific steps are:

[0051] Step 1, select a rectangular magnesium alloy plate with a length and width of 20mm and a thickness of 3mm, and then use silicon carbide water sandpaper to conform to 240 mesh, 480 mesh, 600 mesh, 800 mesh, 1000 mesh, 1200 mesh, 1500 mesh and 2000 mesh respectively. Sequentially, the surface of the magnesium alloy is ground and polished sequentially, and then cleaned with clean water, and placed at room temperature for 5 minutes to dry the surface, thereby obtaining a magnesium alloy with a smooth surface;

[0052] Step 2, first put the polished magnesium alloy plate into an isopropanol ultrasonic cleaner, take it out after cleaning for 3 minutes, and place it at room temperature for 5 minutes to make the surface dry; then perform plasma activation on the magnesium alloy plate, the specific activation process It is: put the magnesium allo...

Embodiment 2

[0058] A preparation of a ceramic membrane with antibacterial function based on magnesium alloy, denoted as ZA1, the specific steps are:

[0059] Step 1, select a rectangular magnesium alloy plate with a length and width of 20mm and a thickness of 3mm, and then use silicon carbide water sandpaper to conform to 240 mesh, 480 mesh, 600 mesh, 800 mesh, 1000 mesh, 1200 mesh, 1500 mesh and 2000 mesh respectively. Sequentially, the surface of the magnesium alloy is ground and polished sequentially, and then cleaned with clean water, and placed at room temperature for 5 minutes to dry the surface, thereby obtaining a magnesium alloy with a smooth surface;

[0060] Step 2, first put the polished magnesium alloy plate into an isopropanol ultrasonic cleaner, take it out after cleaning for 3 minutes, and place it at room temperature for 5 minutes to make the surface dry; then perform plasma activation on the magnesium alloy plate, the specific activation process It is: put the magnesium ...

Embodiment 3

[0068] A preparation of a ceramic film with antibacterial function based on magnesium alloy, denoted as ZA2, the specific steps are:

[0069] Step 1, select a rectangular magnesium alloy plate with a length and width of 20mm and a thickness of 3mm, and then use silicon carbide water sandpaper to conform to 240 mesh, 480 mesh, 600 mesh, 800 mesh, 1000 mesh, 1200 mesh, 1500 mesh and 2000 mesh respectively. Sequentially, the surface of the magnesium alloy is polished and polished in turn, and then cleaned with clean water, and then placed at room temperature for 5 minutes to dry the surface, thereby obtaining a magnesium alloy with a smooth surface; step 2, first put the polished magnesium alloy plate into the isothermal In the propanol ultrasonic cleaner, take it out after cleaning for 3 minutes, and place it at room temperature for 5 minutes to make its surface dry; then perform plasma activation on the magnesium alloy plate, the specific activation process is: put the magnesium...

PUM

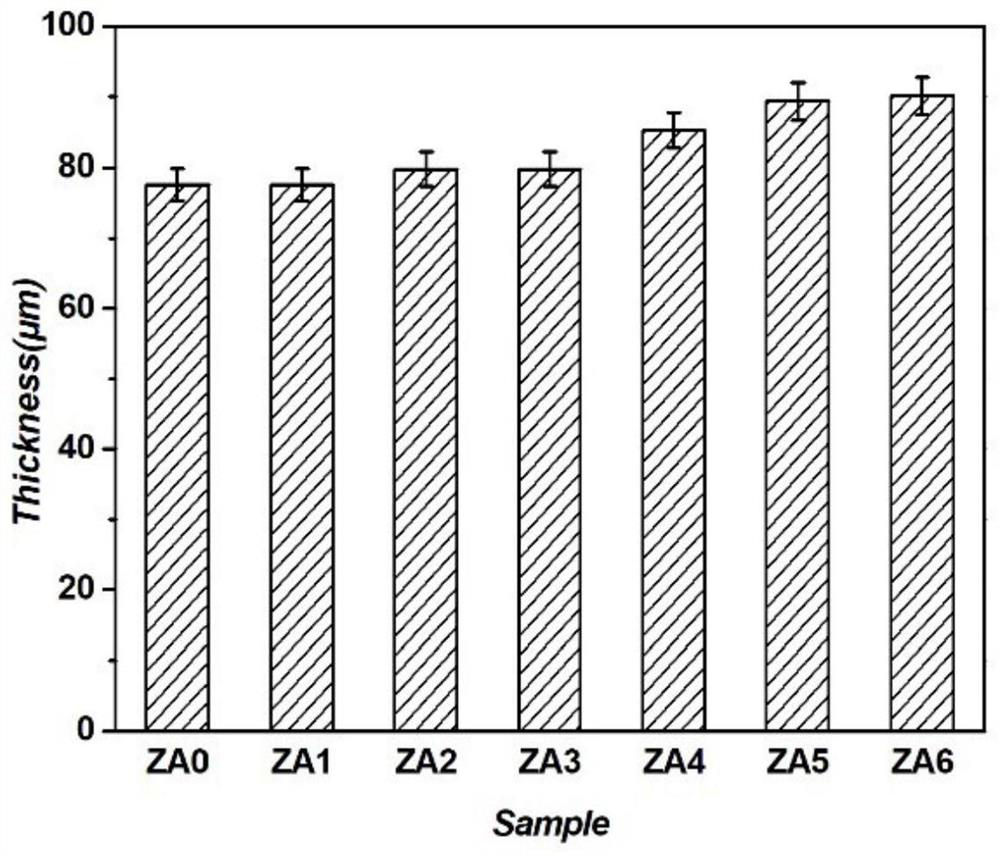

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com