Method for preparing catalytic electrode rich in crystal defects through pulse laser direct writing in liquid nitrogen environment

A pulsed laser, catalytic electrode technology, applied in electrodes, electrode coatings, electrolysis processes, etc., can solve the problems of high consumption of precious metal Pt, poor catalytic stability, low reactivity, etc. Strong control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Nickel foam (NF) was ultrasonically cleaned in distilled water and absolute ethanol for 5 minutes respectively, then soaked in 3M dilute hydrochloric acid for 20 minutes, taken out, washed repeatedly with distilled water, and then dried;

[0027] (2) Soak the NF treated in step (1) in 20 mL of 2mM chloroplatinic acid solution for 4 hours, take it out, wash it with distilled water, and dry it.

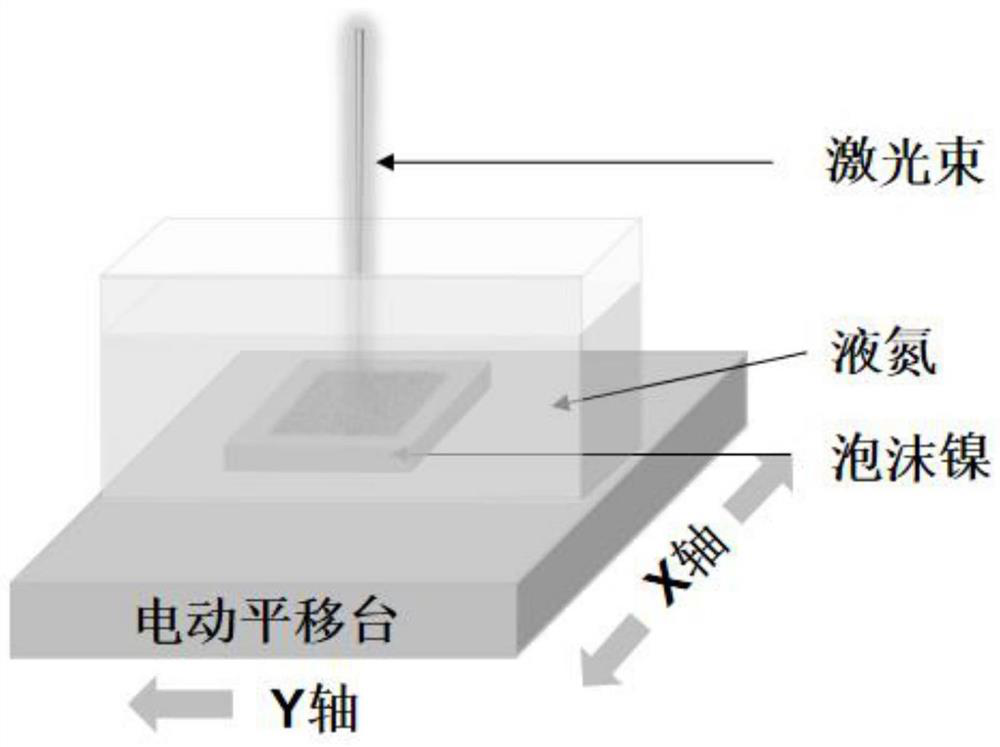

[0028] (3) The NF prepared in step (2) is fixed at the bottom of the open container and poured into liquid nitrogen to keep the liquid nitrogen liquid level higher than the nickel foam, such as figure 1 The synthetic process device diagram is shown.

[0029] (4) At room temperature, a millisecond laser is used to realize a defect-rich platinum-nickel alloy catalytic electrode with the assistance of a translation stage. Set the working range of the millisecond laser on the computer, set the frequency to 1 Hz, the laser energy to 9 J, and use a pulsed laser with a wavelength ...

Embodiment 2

[0033] (1) Nickel foam (NF) was ultrasonically cleaned in distilled water and absolute ethanol for 7 minutes respectively, then soaked in 3M dilute hydrochloric acid for 20 minutes, taken out, washed repeatedly with distilled water, and dried for later use;

[0034] (2) Soak the NF treated in step (1) in 27mL of 2mM chloroplatinic acid solution for 3h, take it out, wash it with distilled water, and dry it for later use.

[0035] (3) Fix the NF prepared in step (2) at the bottom of the open container and pour liquid nitrogen into it to keep the liquid nitrogen level higher than the nickel foam.

[0036] (4) At room temperature, a millisecond laser is used to realize the defect-rich platinum-nickel alloy nanostructure with the assistance of a translation stage. Set the working range of the millisecond laser on the computer, set the frequency to 1.2 Hz, the laser energy to 8 J, and use a pulsed laser with a wavelength of 1064 nm to irradiate for 50 min.

[0037] (5) After the la...

Embodiment 3

[0040] (1) Nickel foam (NF) was ultrasonically cleaned in distilled water and absolute ethanol for 8 minutes respectively, then soaked in 3M dilute hydrochloric acid for 20 minutes, taken out, washed repeatedly with distilled water, and dried for later use;

[0041] (2) Soak the NF treated in step (1) in 25mL of 3mM chloroplatinic acid solution for 4h, take it out, wash it with distilled water, and dry it for later use.

[0042] (3) Fix the NF prepared in step (2) at the bottom of the open container and pour liquid nitrogen into it to keep the liquid nitrogen level higher than the nickel foam.

[0043] (4) At room temperature, a millisecond laser is used to realize the defect-rich platinum-nickel alloy nanostructure with the assistance of a translation stage. Set the working range of the millisecond laser on the computer, set the frequency to 4 Hz, the laser energy to 11 J, and use a pulsed laser with a wavelength of 1064 nm to irradiate for 60 min.

[0044] (5) After the las...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com