Dry granulation slag storage flow control device and slag storage flow control method

A dry granulation and slag storage technology, applied in the field of metallurgy, can solve the problems of heat loss, inability to carry out granulation treatment, low slag temperature, etc., and achieve the effect of ensuring fluidity, heating efficiency and heating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

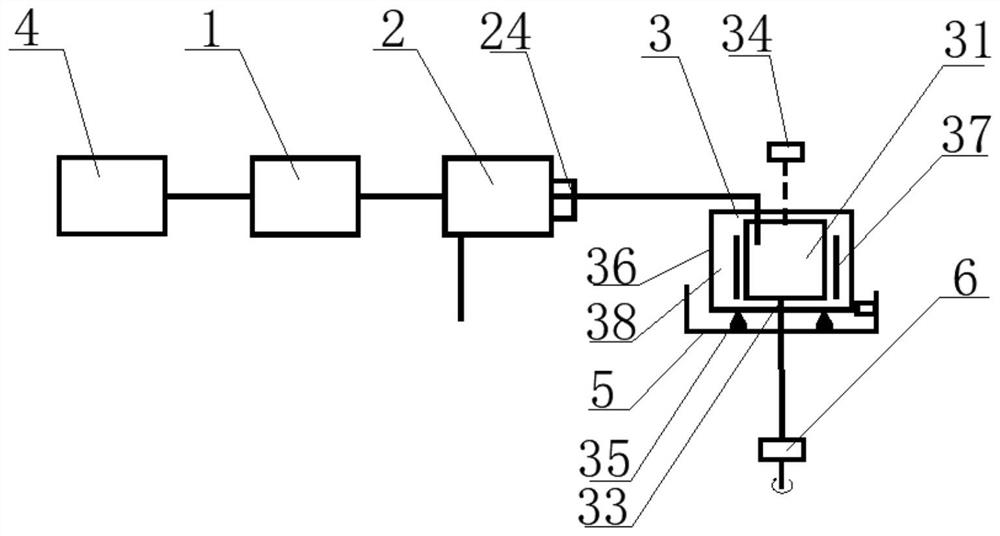

Method used

Image

Examples

Embodiment 1

[0049] The implementation method of this embodiment: Drain 1450°C blast furnace slag directly from the blast furnace through the slag ditch, with a processing capacity of 30t / h.

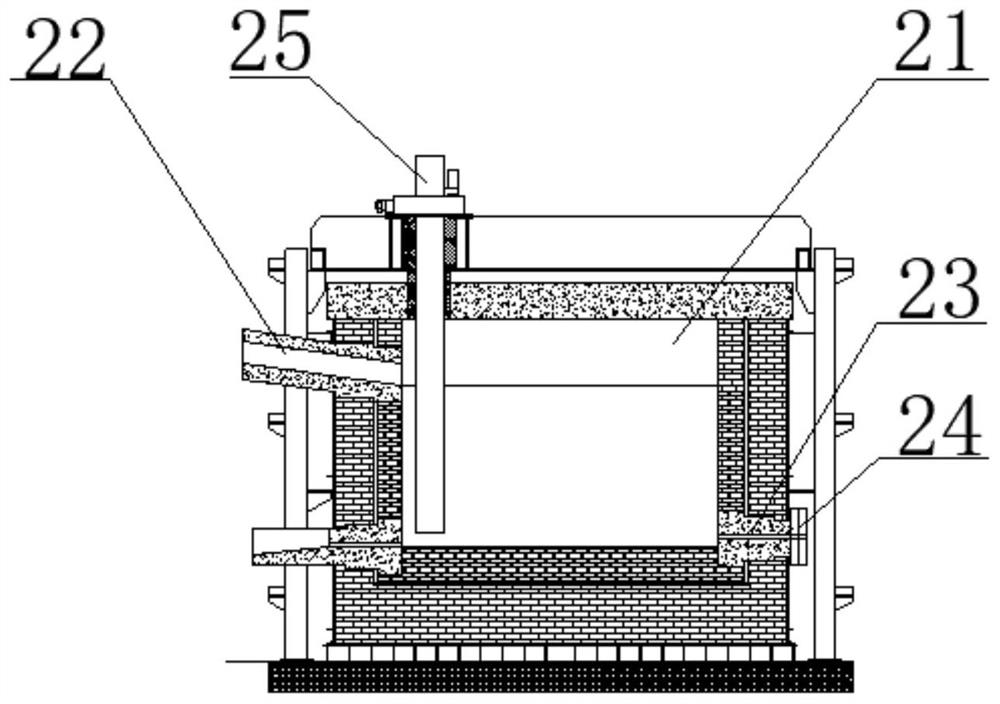

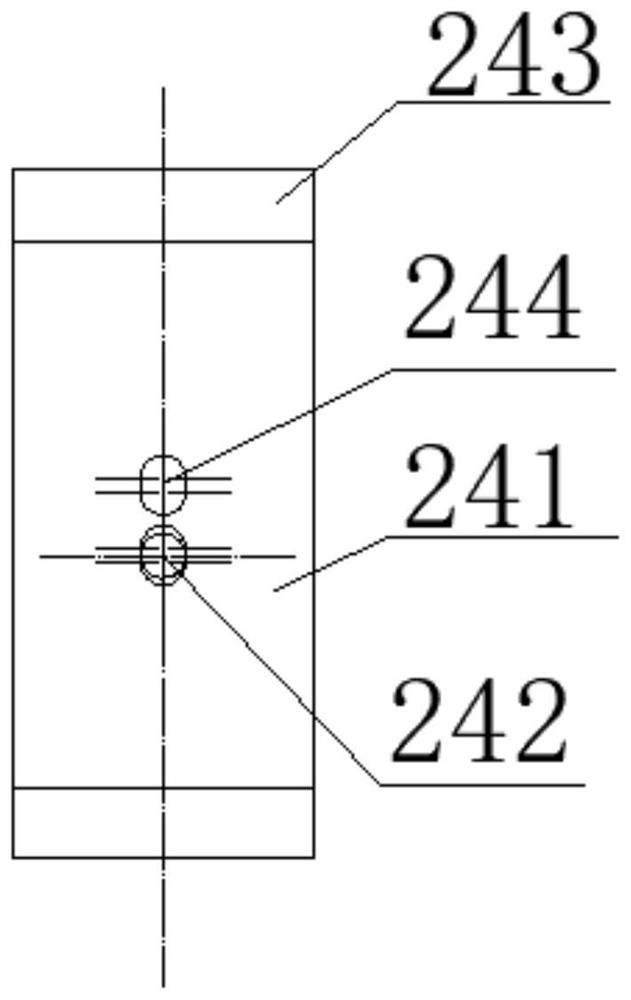

[0050] The volume of the slag storage insulation device 2 is 35m 3 , the slag storage body 21 is built from the inside to the outside by heat-resistant and heat-insulating materials, which are the working layer, heat-insulating layer and heat-insulating layer respectively, and the periphery adopts a metal shell and is supported by a steel structure, and the bottom is arranged in sequence from top to bottom. , Bottom steel plate and supporting steel structure are set under the insulation layer, and the supporting steel structure has good ventilation conditions.

[0051] An AC heating electrode 25 is arranged inside the slag storage main body 21. The number of the AC heating electrodes 25 is three electrodes, and the three electrodes are evenly distributed inside the slag storage main body 21. The powe...

Embodiment 2

[0056] The implementation method of this embodiment: the 1490 ° C blast furnace slag discharged from the blast furnace first flows into the slag tank, and the slag tank is transported to the vicinity of the slag receiving tank, and the slag tank is lifted by a crane, and the molten slag is poured from the slag tank into the slag receiving tank, and then from the slag receiving tank It flows into the slag storage insulation device 2 with a processing capacity of 60t / h.

[0057] The volume of the slag storage insulation device 2 is 35m 3 The slag storage main body 21 is built from heat-resistant and heat-insulating materials from the inside to the outside, which are successively the working layer, the heat-insulating layer and the heat-insulating layer. The periphery is made of a metal shell and supported by a steel structure. Bottom steel plate and supporting steel structure are arranged below, and the supporting steel structure has good ventilation conditions.

[0058] Three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com