Composite polymerization inhibitor and application thereof, high-stability polyether for polycarboxylate superplasticizer and preparation method of high-stability polyether

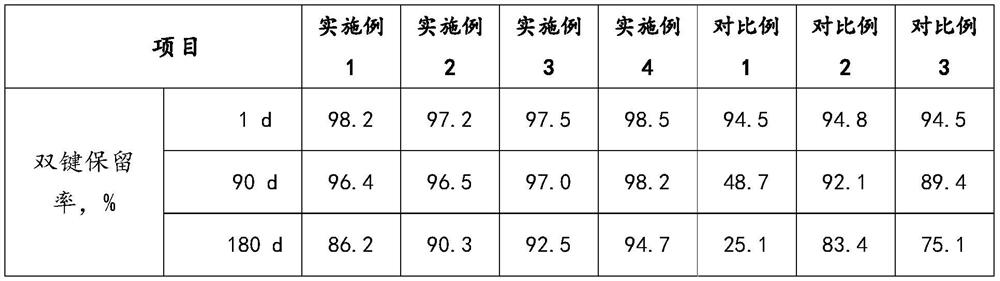

A composite polymerization inhibitor and high-stability technology, used in composite polymerization inhibitor and its application, high-stability polyether for polycarboxylate water reducer and its preparation field, can solve the problem that polyether macromonomer is easy to degrade, Poor stability and other problems, to achieve the effect of not easy to decompose, high stability, good polymerization inhibition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a method for preparing a compound inhibitor and a highly stable polyether for polycarboxylate water reducing agent, which comprises the following steps:

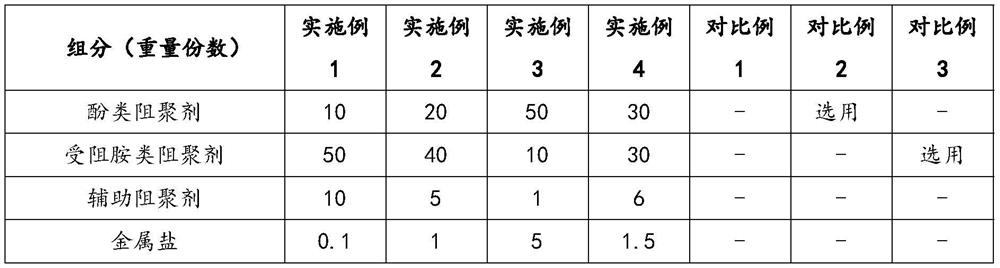

[0025] (1) In parts by weight, weigh 10 to 50 parts of phenolic polymerization inhibitors, 10 to 50 parts of hindered amine polymerization inhibitors, 1 to 10 parts of auxiliary polymerization inhibitors, 0.1 to 5 parts of metal salts and 0.5 to 5 parts of part emulsifier;

[0026] (2) Put the above-mentioned raw material components into the preparation tank, raise the temperature to 40-60°C, use a high-speed dispersing shearer to stir the raw material components, and form a homogeneous composite inhibitor after stirring for 30-60 minutes, wherein , the stirring speed is 500~8000rpm / min.

[0027] (3) In parts by weight, add 100 parts of solvent to the composite polymerization inhibitor obtained in step (2), and continue stirring for 30 to 60 minutes to obtain a composite polymeriza...

Embodiment 1

[0041] (1) Add phenolic polymerization inhibitors, hindered amine polymerization inhibitors, auxiliary polymerization inhibitors, metal salts and emulsifiers to the polymerization inhibitor preparation tank, raise the temperature to 40 ° C, and use a high-speed dispersing shear to stir , the stirring speed is 6000rpm / min, and after stirring for 30min, a composite inhibitor in a homogeneous state is formed. Then add 100 parts of deionized water in above-mentioned composite polymerization inhibitor, continue to stir 60min, obtain the composite polymerization inhibitor emulsion that is emulsion state;

[0042] Among them, the composite inhibitor is compounded according to the following mass ratio: 10 parts of 2-(5-chloro-2-benzenetriazolyl)-6-tert-butyl-4-methylphenol, 50 parts of 4-hydroxy-2 , 2,6,6-tetramethylpiperidine-1-oxyl radical, 10 parts of dilauryl thiodipropionate, 0.1 part of bis(N,N-dibutyldithiocarbamate) copper and 5 Parts Emulsifier 1360.

[0043] (2) Carry out ...

Embodiment 2

[0046] (1) Add phenolic polymerization inhibitors, hindered amine polymerization inhibitors, auxiliary polymerization inhibitors, metal salts and emulsifiers to the polymerization inhibitor preparation tank, raise the temperature to 40 ° C, and use a high-speed dispersing shear to stir , the stirring speed is 8000rpm / min, and after stirring for 60min, a composite inhibitor in a homogeneous state is formed. Then add 100 parts of deionized water in above-mentioned composite polymerization inhibitor, continue to stir 60min, obtain the composite polymerization inhibitor emulsion that is emulsion state;

[0047] Among them, the composite polymerization inhibitor is compounded according to the following mass ratio: 20 parts of 2,4-dimethyl-6-tert-butylphenol, 40 parts of 4-benzoyloxy-2,2,6,6-tetra Methylpiperidine-1-oxyl radical, 5 parts ditetradecyl 3,3'-thiodipropionate, 1 part basic copper carbonate, and 0.5 parts Emulsifier 1340.

[0048] (2) Carry out air tightness inspection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com