Bearing raceway superfinishing device

A technology of bearing raceway and superfinisher, which is applied in the field of bearing superfinishing, can solve the problems of singleness and high limitation, and achieve the effect of strong mobility, convenient and flexible installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

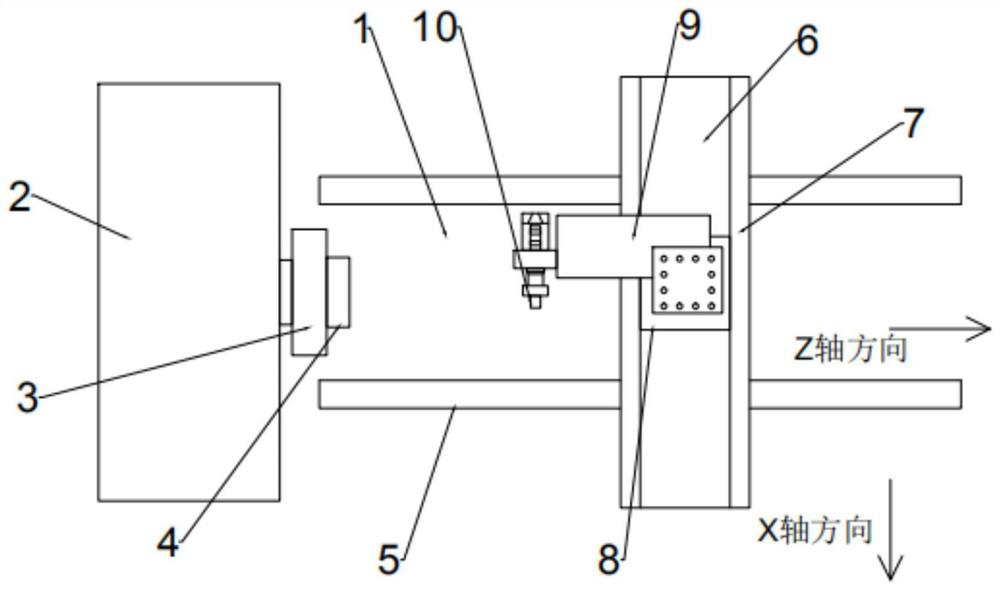

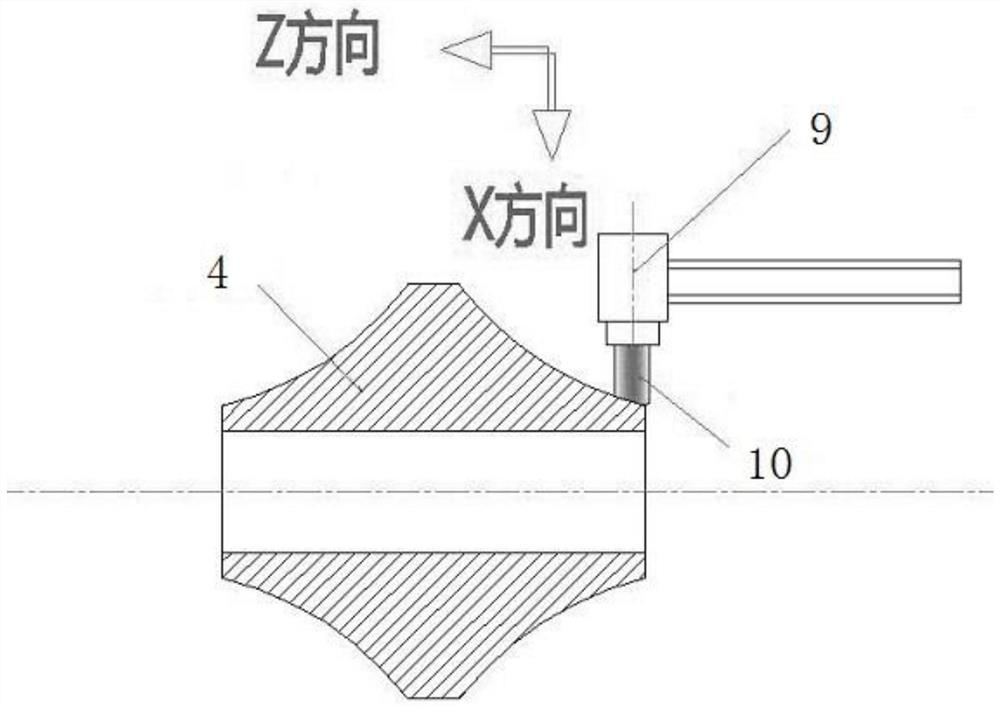

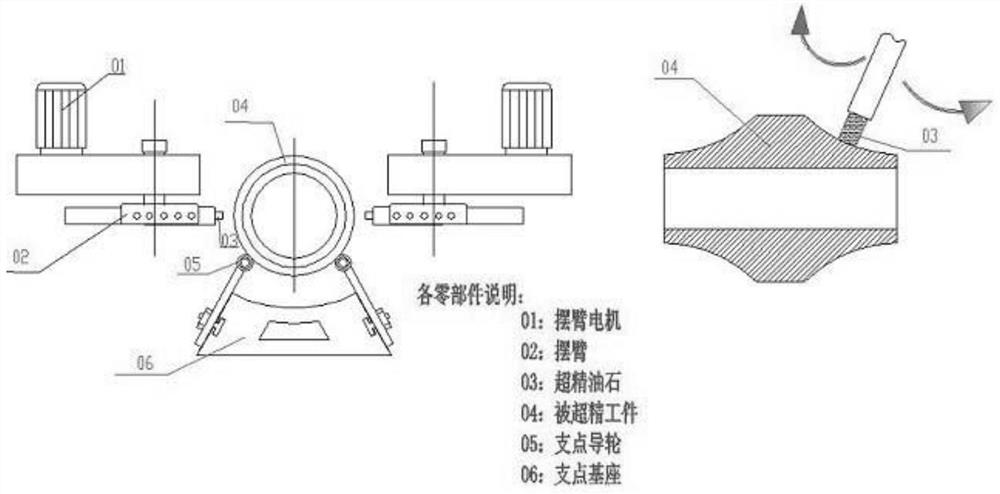

[0022] Embodiment: According to the raceway shape and technical requirements of the bearing, choose the oilstone with corresponding particle size and hardness, and put it into the superfinishing component; according to the specifications and models of different superfinishing products, select the corresponding online equipment and the corresponding workpiece Tooling, set system program. The running trajectory of the superfine device is controlled online through the system. The superfinisher can realize the superfinishing of any shape of the raceway, because of its own flexibility, it can be mounted on any CNC machine tool, the horizontal slide rail and the horizontal carriage control the Z-axis direction feed, the longitudinal slide rail and the longitudinal slide The block controls the X-axis feed, which is realized by the synchronous cross-feed of the X-axis and Z-axis. When superfinishing the outer raceway of the superfinished workpiece, it is only necessary to reverse the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com