Processing device and method for manufacturing artware by utilizing waste garbage

A technology for processing devices and handicrafts, which is applied in the fields of solid waste removal, chemical instruments and methods, transportation and packaging, etc. It can solve the problems of difficult disposal of industrial waste and achieve the effect of ensuring crushing efficiency and crushing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

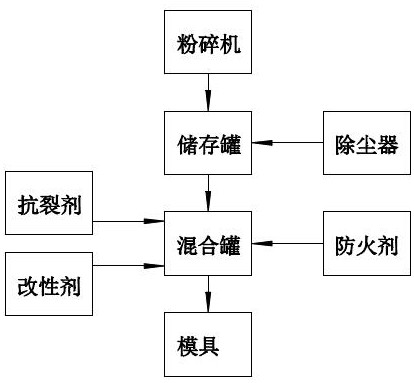

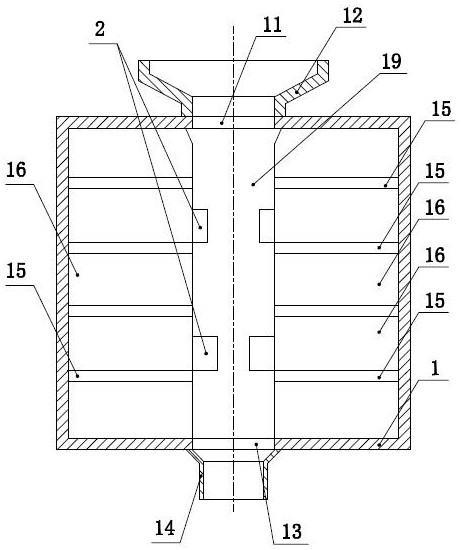

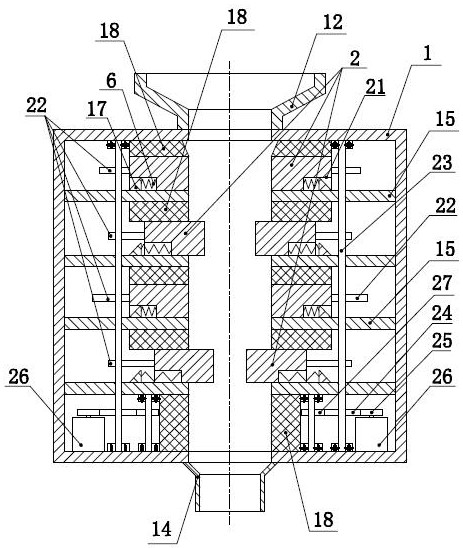

[0034] Such as Figure 1 to Figure 11 As shown, the processing device of the present invention mainly includes a pulverizer 1, a storage tank, a dust collector, a mixing tank 4 and a mould, and the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] Such as Figure 1 to Figure 3 As shown, the shredder 1 is used for shredding and processing industrial waste, so that the size of industrial solid waste is reduced to an appropriate size. A waste inlet 11 is provided on the top of the pulverizer, and a hopper 12 connected to the waste inlet is provided above the pulverizer. The upper end of the hopper is large and the bottom end is small, and is used to receive solid waste. A waste outlet 13 is provided at the bottom of the pulverizer, and a discharge pipe 14 communicating with the waste outlet 13 is fixed at the bottom of the pulverizer. The pulverized waste inside the pulverizer enters the discharge pipe through the waste o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com