Stalk pickup and chopping machine

A shredder and straw technology, applied in the direction of cutters, loaders, harvesters, etc., can solve the problems of insufficient straw crushing and troublesome processing, and achieve the effects of flexible and convenient operation, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings.

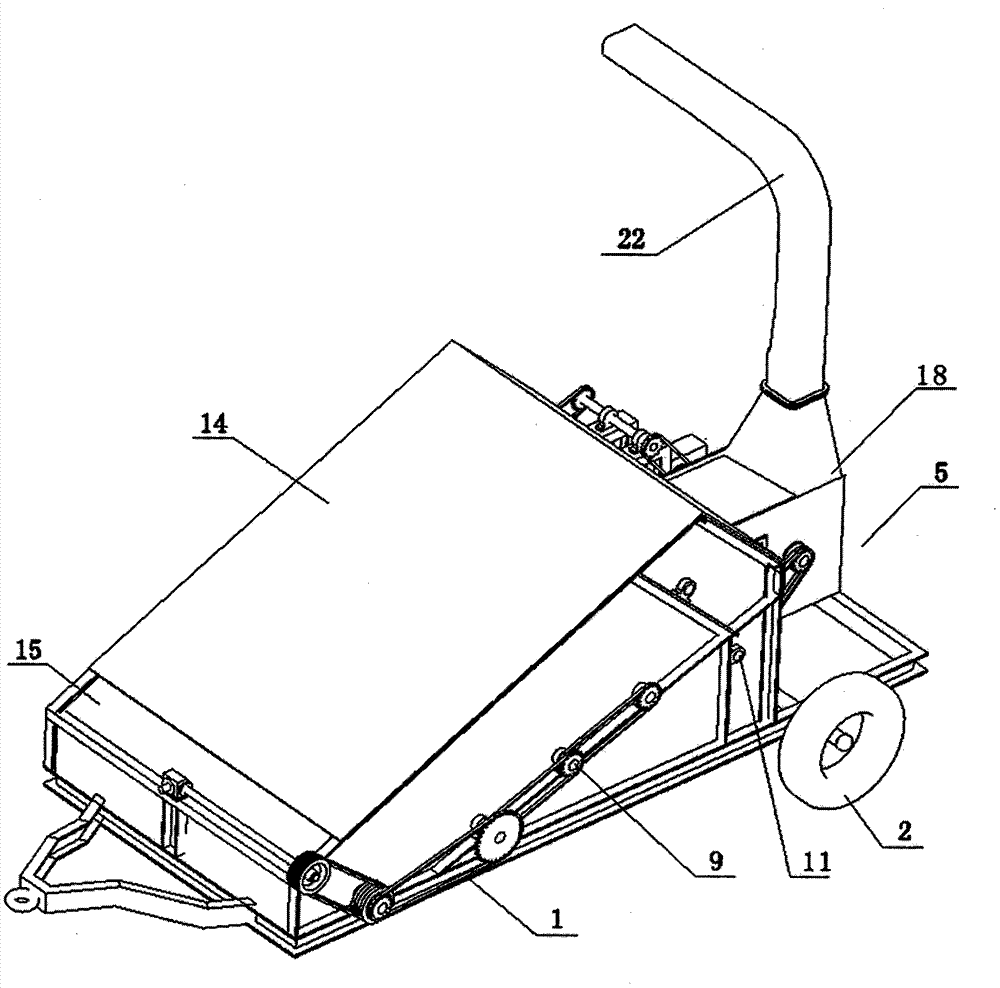

[0020] Such as Figure 1 to Figure 5 As shown, the straw picking and shredding machine includes a frame 1, a walking wheel 2, a transmission mechanism, a cutting picker 3, a feeder 4, and a guillotine throwing machine 5, which are arranged on the frame 1 from front to back. Cutting picker 3, conveyor screen 6, feeder 4 and guillotine thrower 5;

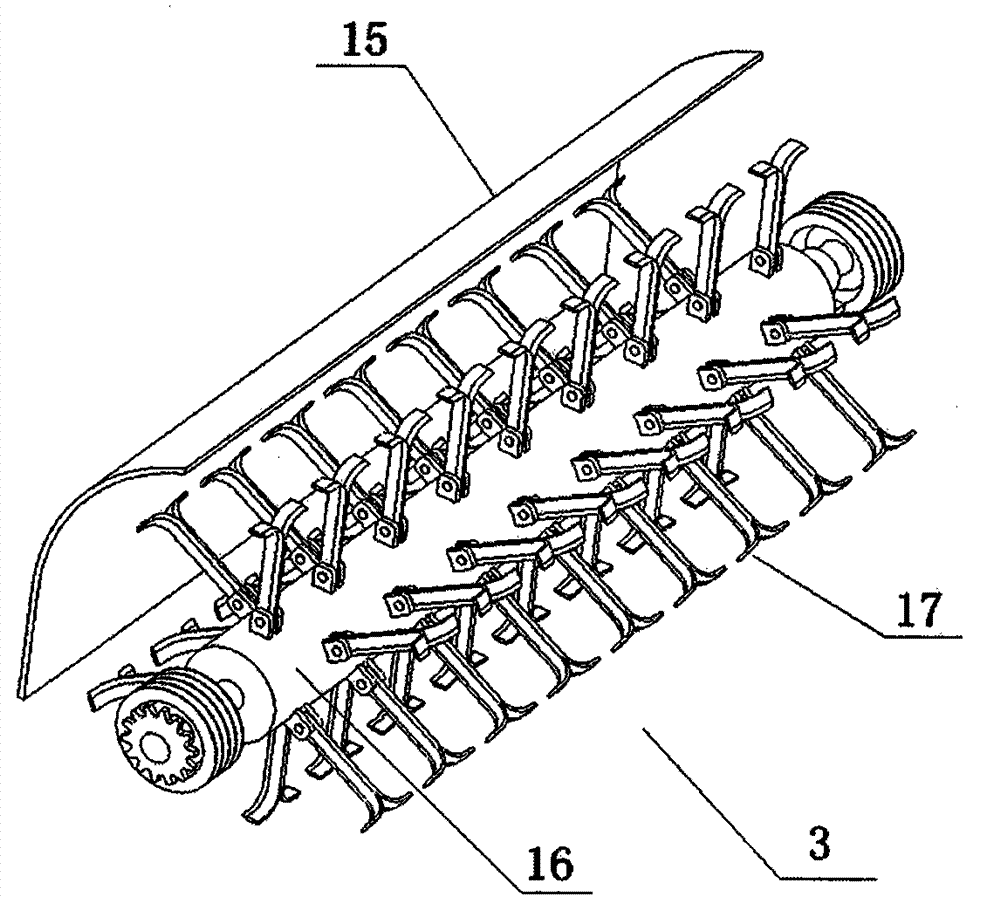

[0021] The conveying screen 6 includes a soil sieve grate 7, three grass picking shafts 8 driven by a transmission mechanism are arranged under the soil sieve grates 7, and a shifting mechanism driven by a transmission mechanism is provided at the rear of the soil sieve grates 7 The grass shaft 8, 14 grass-pull wheels 9 are fixed on each grass-pull shaft 8, and each grass wheel 9 has three arc-shaped grass-pull claws;

[0022] The feeder 4 includes a feeding trough 10 provided between the sieve grate 7 and the feed opening of the cutting and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com