Gel electrolyte for aqueous zinc-manganese battery and preparation method of gel electrolyte

A technology of gel electrolyte and gel layer, applied in electrolytes, electrolyte immobilization/gelation, secondary batteries, etc., can solve the problems of poor reversibility of manganese-dissolved batteries, etc., to prevent the growth of zinc dendrites and prevent Corrosion, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

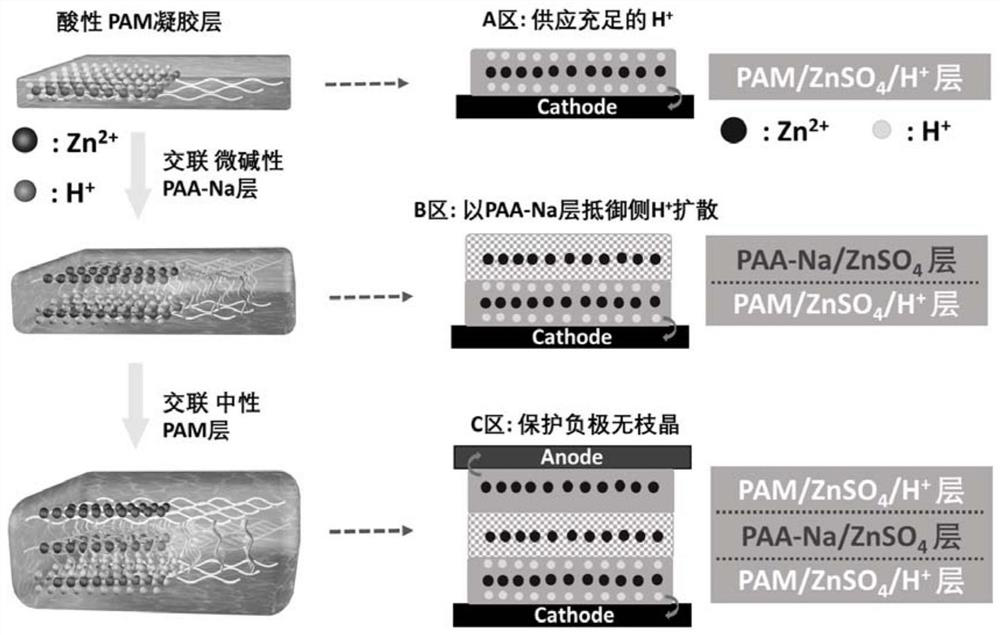

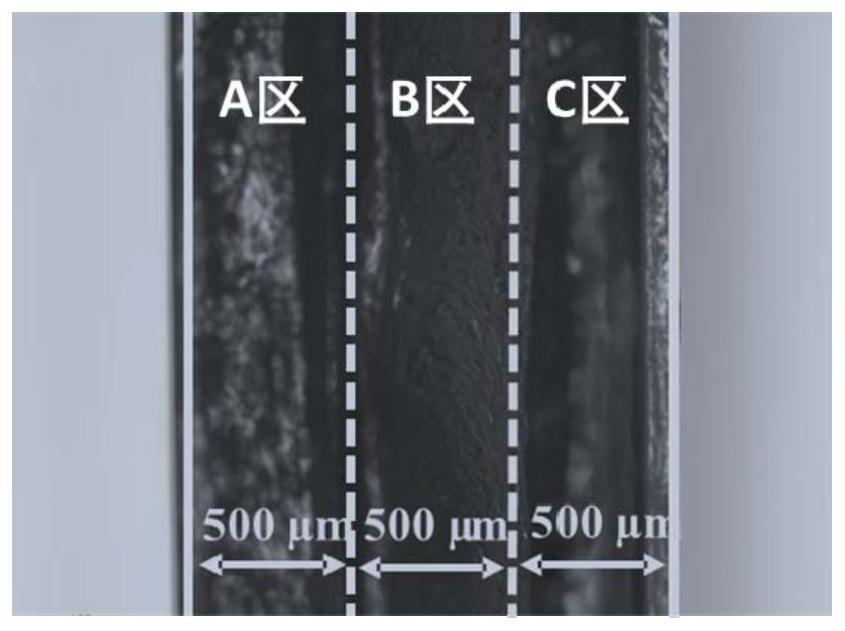

[0029] A three-layer gel electrolyte, the preparation method specifically includes the following steps:

[0030] (1) Preparation of acidic polyacrylamide (PAM) gel layer

[0031] Add 0.25mg / L acrylamide (AM) to 2M ZnSO 4 and 0.05M H 2 SO 4 In the mixed solution, stir well until the acrylamide is completely dissolved, then add a small amount of 75g / L ammonium persulfate (APS) and 25g / L N,N'-methylenebisacrylamide (MBA) in order to promote gelation Stir at room temperature for 30 minutes, inject the mixed solution into a special mold with a thickness of 1.5mm, and then move the mold into a drying oven at 50°C for thermal initiation for 2 hours to obtain an acidic polyacrylamide gel layer;

[0032] (2) Preparation of slightly alkaline sodium polyacrylate gel layer

[0033] The mass fraction is 35% sodium acrylate, 75g / L APS, 25g / L MBA and 2M ZnSO 4 Mix the solutions, stir evenly, transfer the obtained mixed solution to a special mold with a thickness of 1.5mm in step (1), an...

Embodiment 2

[0037] An aqueous zinc-manganese battery, the preparation method specifically comprising the following steps:

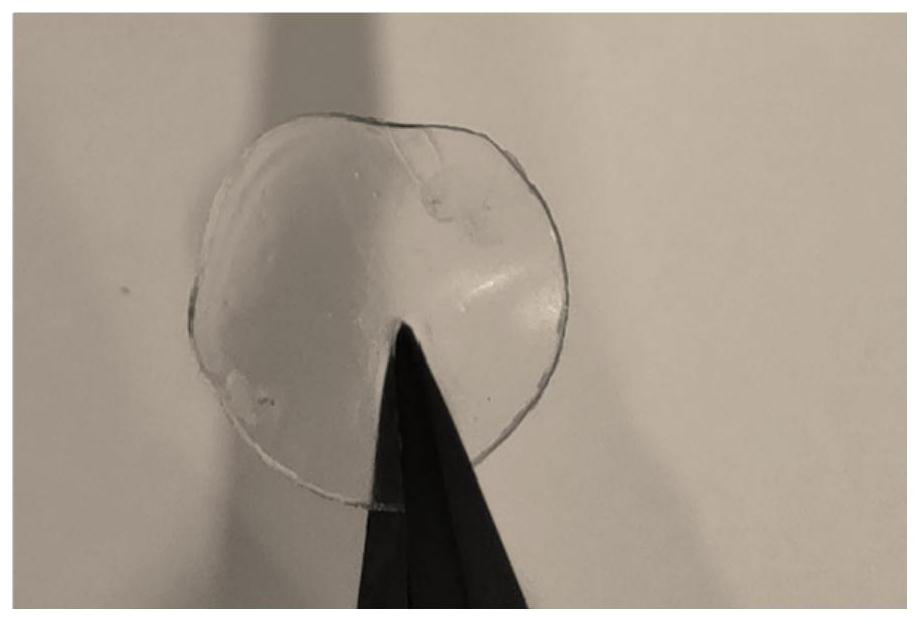

[0038] (1) Cut the three-layer gel electrolyte prepared in Example 1 into discs with a diameter of 16 mm;

[0039] (2) cutting a titanium sheet with a diameter of 12mm, and coating the α-type manganese oxide active material on the titanium sheet as a positive electrode; cutting a zinc sheet with a diameter of 12mm as a negative electrode;

[0040](3) Use the three-layer gel electrolyte disc prepared in step (1) as the electrolyte / diaphragm to separate the positive and negative electrodes, and package it into a button battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com