Large-cylinder-diameter forged steel piston and manufacturing method thereof

A manufacturing method and large bore technology, applied to pistons, engine components, machines/engines, etc., can solve the problems of large size and weight, low piston strength, etc., and achieve the effects of weight reduction, improved service life, and good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

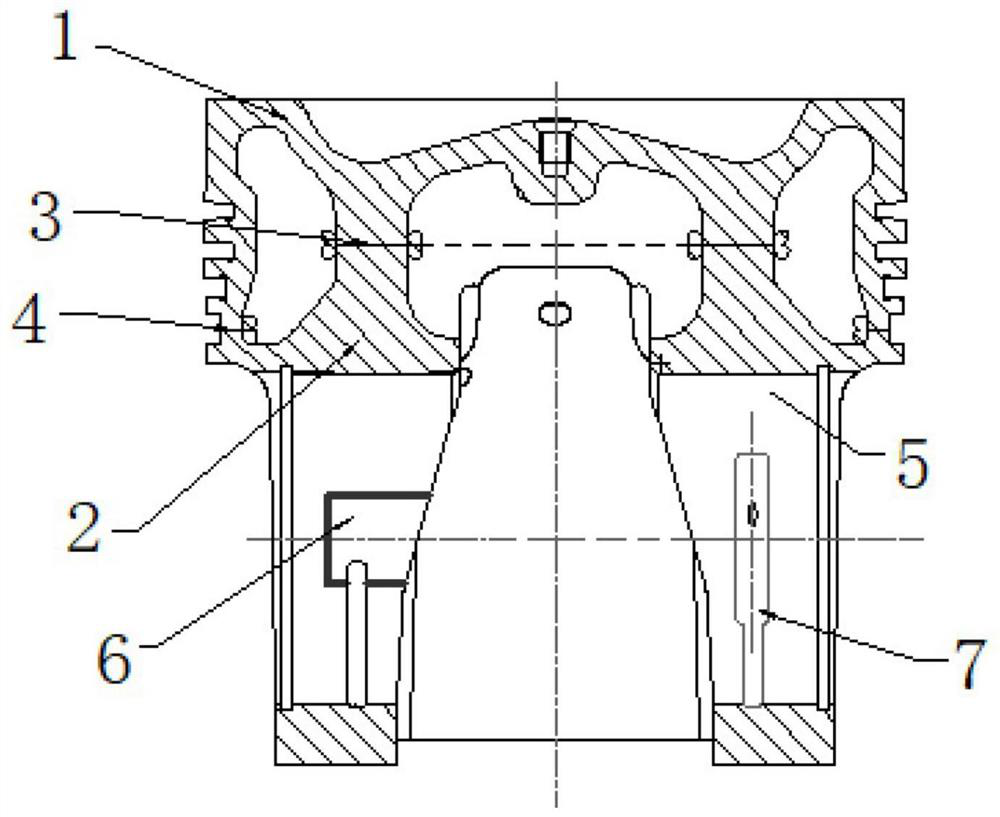

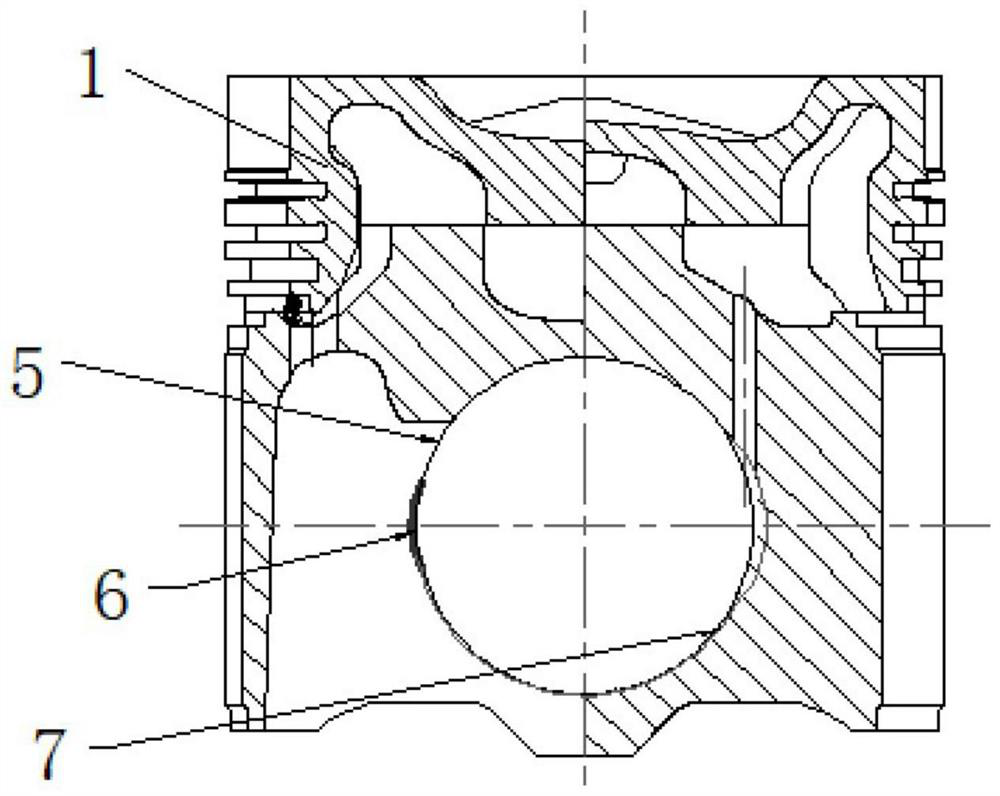

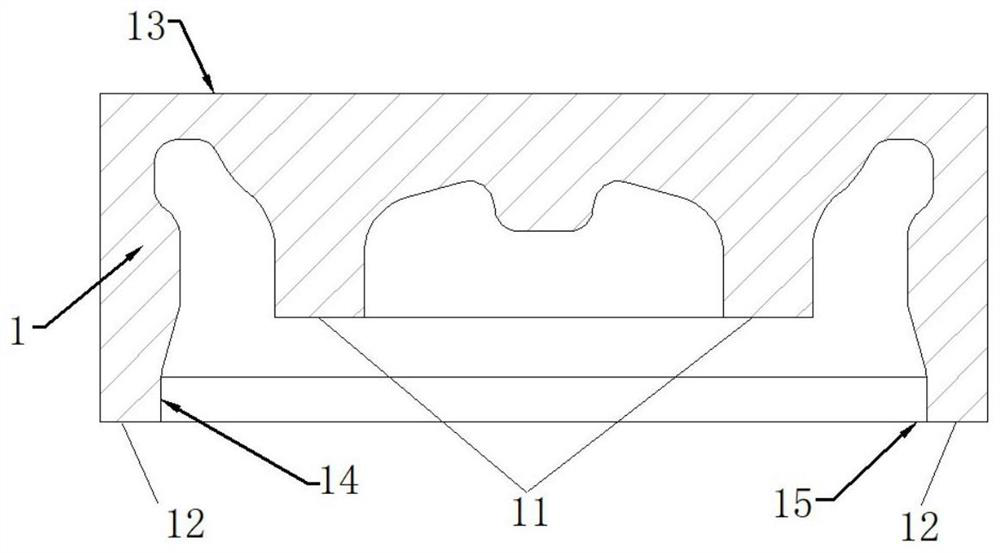

[0033] Embodiment: a kind of large bore forged steel piston, as attached figure 1As shown, the forged steel piston includes a forged steel piston crown 1, a forged steel piston skirt 2 and a piston pin hole 5, and the forged steel piston crown 1 and the forged steel piston skirt 2 are connected by inertia friction welding, as shown in the attached image 3 , 4 As shown in and 5, the forged steel piston crown 1 in this embodiment includes an inner ring connection surface 11, an outer ring connection surface 12, a combustion surface 13, a sleeve diameter 14 and a cooling surface 13; the forged steel piston skirt 2 in this embodiment Including the inner ring receiving surface 21 inertial friction welding with the inner ring connection surface 11, the outer ring receiving surface 22 inertial friction welding with the outer ring connection surface 12, the mouth end 23, and the oil hole 24; the inner ring in this embodiment The weld between the connection surface 11 and the inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com