Preparation method of VN19 vanadium-nitrogen alloy and sagger device

A technology of vanadium-nitrogen alloy and VN19, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of complex operation and high cost, achieve good nitriding effect, reduce preparation cost, and shorten nitriding the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of VN19 vanadium nitrogen alloy, comprises the following steps:

[0027] After mixing powdery vanadium oxide, silicon dioxide powder, carbonaceous reducing agent, iron powder and binder, carry out ball pressing, drying, vacuum carbonization reduction and nitriding in sequence to obtain VN19 vanadium nitrogen alloy; the vacuum carbonization reduction The temperature is ≤1450°C, the time is ≤2.5h; the nitriding is carried out under nitrogen, the nitrogen pressure of the nitriding is ≥0.3MPa, and the time is ≤3h.

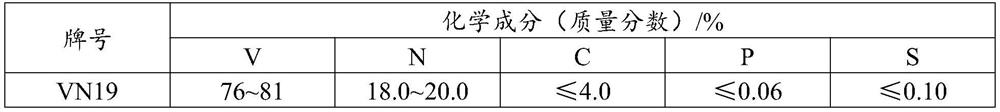

[0028] In the present invention, the VN19 vanadium-nitrogen alloy is specifically the VN19 brand vanadium-nitrogen alloy in GB / T20567-2020, and the specific composition indicators are shown in Table 1:

[0029] Table 1 Chemical Composition of VN19 Vanadium Nitrogen Alloy

[0030]

[0031] The invention mixes powdered vanadium oxide, silicon dioxide powder, carbonaceous reducing agent, iron powder and binder...

Embodiment 1

[0055] The vanadium pentoxide powder, 98% quartz powder, graphite powder and iron powder are mixed according to the mass ratio of 100:3:29:0.4, after mixing, the pellets are pressed and dried. The dry balls are put into the graphite sagger, and the bottom of the graphite sagger is provided with a number of through holes; the graphite bottom plate is placed in a vacuum furnace, and the surface of the graphite bottom plate is provided with a strip groove, and the bottom of the groove is provided with a nitrogen inlet hole, and the nitrogen gas is passed through. The hole is connected with the nitrogen inlet of the vacuum furnace; the graphite sagger is placed in the vacuum furnace and placed on the surface of the graphite bottom plate, and the bottom of the graphite sagger covers the groove on the surface of the graphite bottom plate.

[0056] Close the door of the vacuum furnace, turn on the vacuum pump, pump the vacuum in the furnace to 95Pa, start power supply for rapid heatin...

Embodiment 2

[0058] Vanadium trioxide powder, 98% quartz powder, graphite powder and starch are mixed according to the mass ratio of 100:3:26.5:3, after mixing, the pellets are pressed and dried. The dry balls are put into the graphite sagger, and the bottom of the graphite sagger is provided with a number of through holes; the graphite bottom plate is placed in a vacuum furnace, and the surface of the graphite bottom plate is provided with a strip groove, and the bottom of the groove is provided with a nitrogen inlet hole, and the nitrogen gas is passed through. The hole is connected with the nitrogen inlet of the vacuum furnace; the graphite sagger is placed in the vacuum furnace and placed on the surface of the graphite bottom plate, and the bottom of the graphite sagger covers the groove on the surface of the graphite bottom plate.

[0059] Close the door of the vacuum furnace, turn on the vacuum pump, pump the vacuum in the furnace to 88Pa, start power supply for rapid heating, the fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com