Preparation method of high-dispersity graphene

A high-dispersity, graphene-based technology, applied in chemical instruments and methods, dyed low-molecular-weight organic compound treatment, inorganic chemistry, etc., can solve the problem of limiting the wide application of graphene, affecting the performance of graphene's excellent properties, and reducing graphene adsorption. ability and other problems, to achieve the effect of simple and easy preparation method, excellent dispersibility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

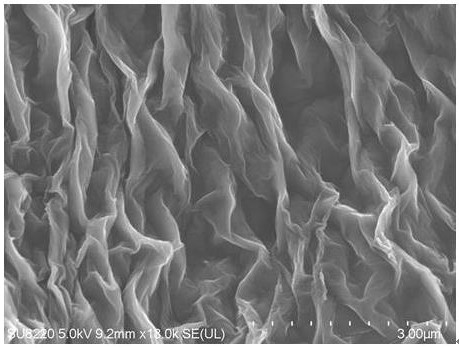

Image

Examples

Embodiment 1

[0023] A preparation method of highly dispersed graphene, comprising the following steps:

[0024] (1) Take 70 mL of 0.5 M hydrochloric acid solution, 30 mg of graphene and 47 mg (0.5 mmol) of 4-aminopyridine in a 200 mL round bottom flask, and sonicate for 30 min.

[0025] (2) Add 15 mL (0.5 mmol) sodium nitrite aqueous solution and sonicate for 30 min at 0 °C, then add some sodium hydroxide and sonicate for 1 h.

[0026] (3) Neutralize and remove excess sodium hydroxide with excess dilute hydrochloric acid, and wash with water, ethanol, and acetone in turn until the filtrate is colorless, and finally dry at room temperature to obtain the highly dispersible graphene.

Embodiment 2

[0028] A preparation method of highly dispersed graphene, comprising the following steps:

[0029] (1) Take 70 mL of 0.5 M hydrochloric acid solution, 30 mg of graphene and 188 mg (2 mmol) of 4-aminopyridine in a 200 mL round bottom flask, and sonicate for 30 min.

[0030] (2) Add 15 mL (2 mmol) sodium nitrite aqueous solution and sonicate for 30 min at 0 °C, then add some sodium hydroxide and sonicate for 1 h.

[0031] (3) Neutralize and remove excess sodium hydroxide with excess dilute hydrochloric acid, and wash with water, ethanol, and acetone in turn until the filtrate is colorless, and finally dry at room temperature to obtain the highly dispersible graphene.

Embodiment 3

[0033] A preparation method of highly dispersed graphene, comprising the following steps:

[0034] (1) Take 70 mL of 0.5 M hydrochloric acid solution, 30 mg of graphene and 376 mg (4 mmol) of 4-aminopyridine in a 200 mL round bottom flask, and sonicate for 30 min.

[0035] (2) Add 15 mL (4 mmol) sodium nitrite aqueous solution and sonicate for 30 min at 5 °C, then add some sodium hydroxide and sonicate for 1.5 h.

[0036] (3) Neutralize and remove excess sodium hydroxide with excess dilute hydrochloric acid, and wash with water, ethanol, and acetone in turn until the filtrate is colorless, and finally dry at room temperature to obtain the highly dispersible graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com