Preparation process of table tennis bat rubber

A table tennis racket and a preparation technology, which is applied to household components, applications, household appliances, etc., can solve the problems of insufficient rubber elasticity or hardness, high technical requirements for manual operation, and rough contours around the rubber, so as to reduce manual operations As well as the workload, the effect of improving the quality of pasting and improving the quality of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation process for table tennis racket rubber, comprising the following steps;

[0034](1) After initially mixing 60 parts by weight of natural rubber, 15 parts by weight of trans-1,4-polyisoprene rubber and 25 parts by weight of butadiene rubber, knead for 3 minutes at 120 ° C on a rubber mixer Add 3 parts by weight of coloring agent while mixing; Then add 12 parts by weight of polymethyl methacrylate, 18 parts by weight of polyvinylimidazole, and 12 parts by weight of polyacrylonitrile and mix for 3 minutes at 120 ° C on the rubber mixer. Then add 1 part by weight of 2,2,4-trimethyl-1,2-dihydroquinoline polymer and 7 parts by weight of zinc carbonate and mix for 3 minutes, then debinding at 90-110°C, and then add 0.8 parts by weight 2,2'-dithiodibenzothiazole and 0.8 parts by weight of sulfur were mixed at 80-100°C for 3 minutes to obtain a compound compound;

[0035] (2) Add the mixed rubber material obtained in step (1) to the calender to calender the sheet....

Embodiment 2

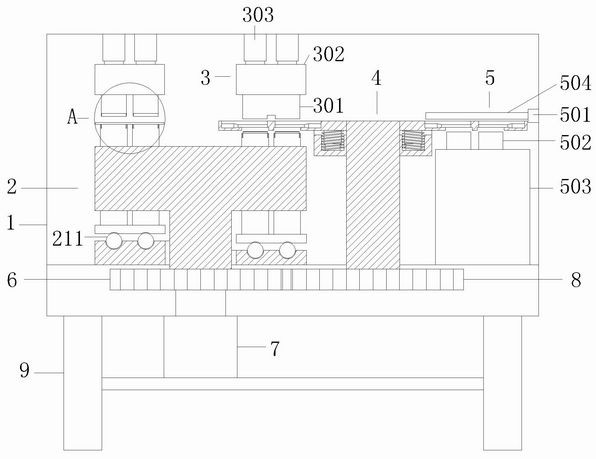

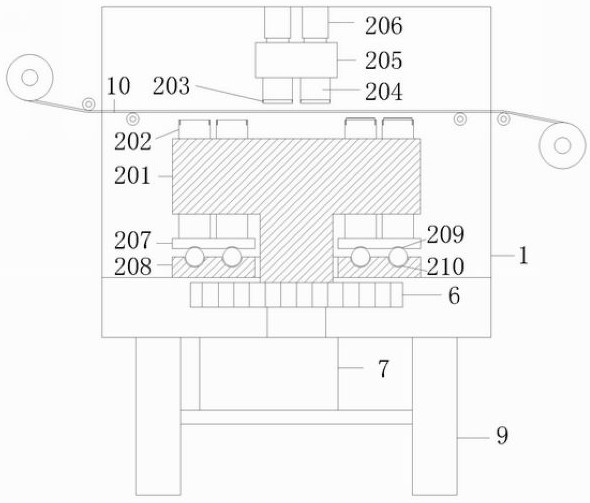

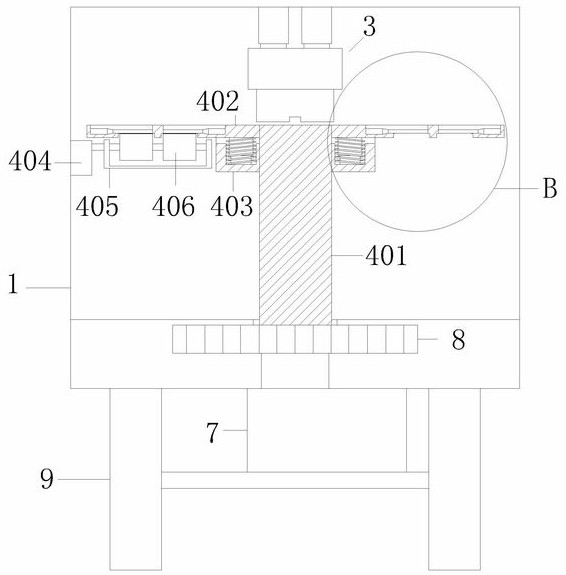

[0038] A preparation device for the preparation process of table tennis racket rubber, including a rubber mixing machine, a calender and a table tennis racket assembly machine, the table tennis racket assembly machine includes a box body 1, a support frame 9 is provided below the box body 1, and the rubber is unwound The roller is placed behind the box body 1, and the rubber winding roller is placed in front of the box body 1. The rear side and the front side of the box body 1 are respectively equipped with a rubber inlet and a rubber outlet. Both sides of the rubber inlet are provided with supporting rollers. There are supporting rollers on both sides, and the rubber is placed on the supporting rollers to pass through the box body 1; the box body 1 is equipped with a cutting mechanism 2, a glue applying mechanism 4, a pressing mechanism 3 and a shooting mechanism 5; a cutting mechanism 2 It includes a rubber unwinding roller, a cutting table 202, a first turntable 201 and a cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com