Manufacturing method of patch type thrust pressure gas bearing

A technology of gas bearing and manufacturing method, which is applied to sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of inability to achieve material selection differentiation, limited groove accuracy, high batch processing costs, etc. Differentiation of selection and material handling, increase processing difficulty and cost, and facilitate mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for manufacturing a patch type thrust pressurized gas bearing, comprising the following steps:

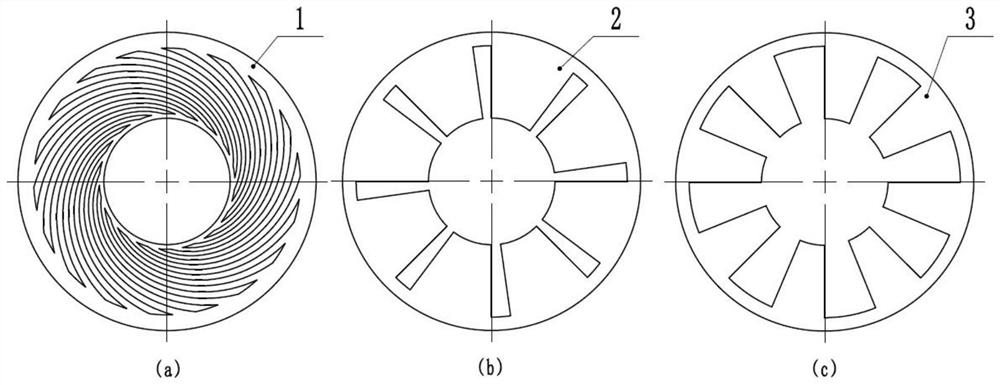

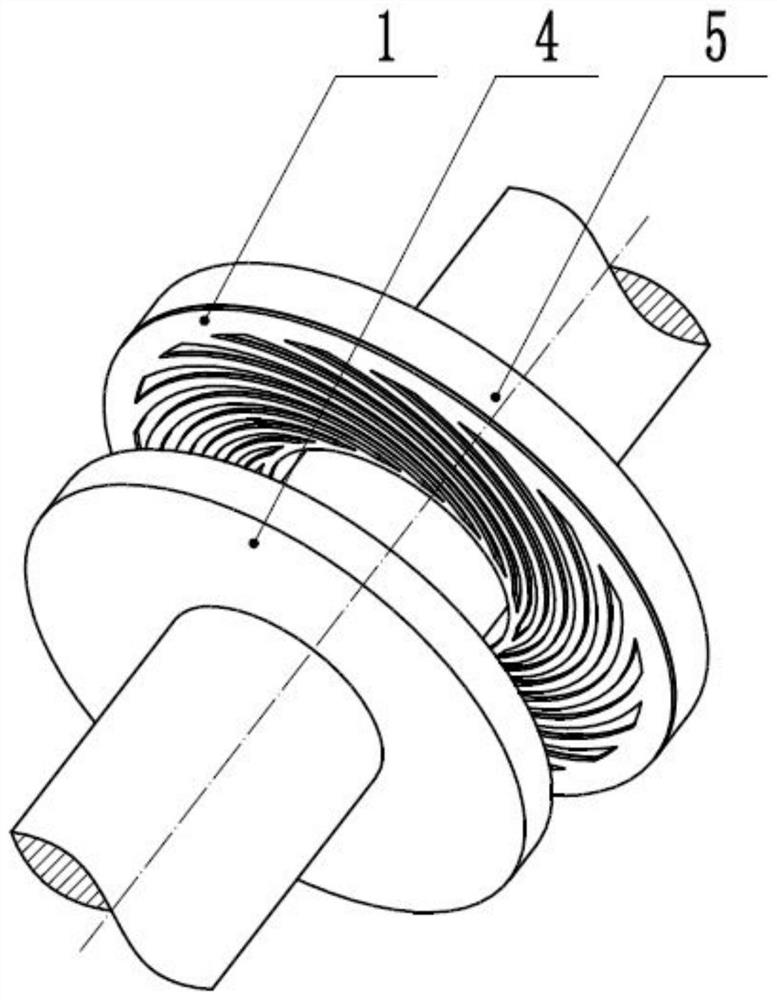

[0039] 1) Provide general metal foil. The size specification of the metal foil is selected to be compatible with the micro-groove specification and the bearing working surface specification. The metal foil is subjected to rapid material reduction processing as required to obtain part of the structure and micro-groove of the removed material. Specific-shaped planar metal foils (stepped first stage) 2 and specific-shaped planar metal foils (stepped second stage) 3 based on structural correspondence, see respectively figure 1 (b) and figure 1 (c).

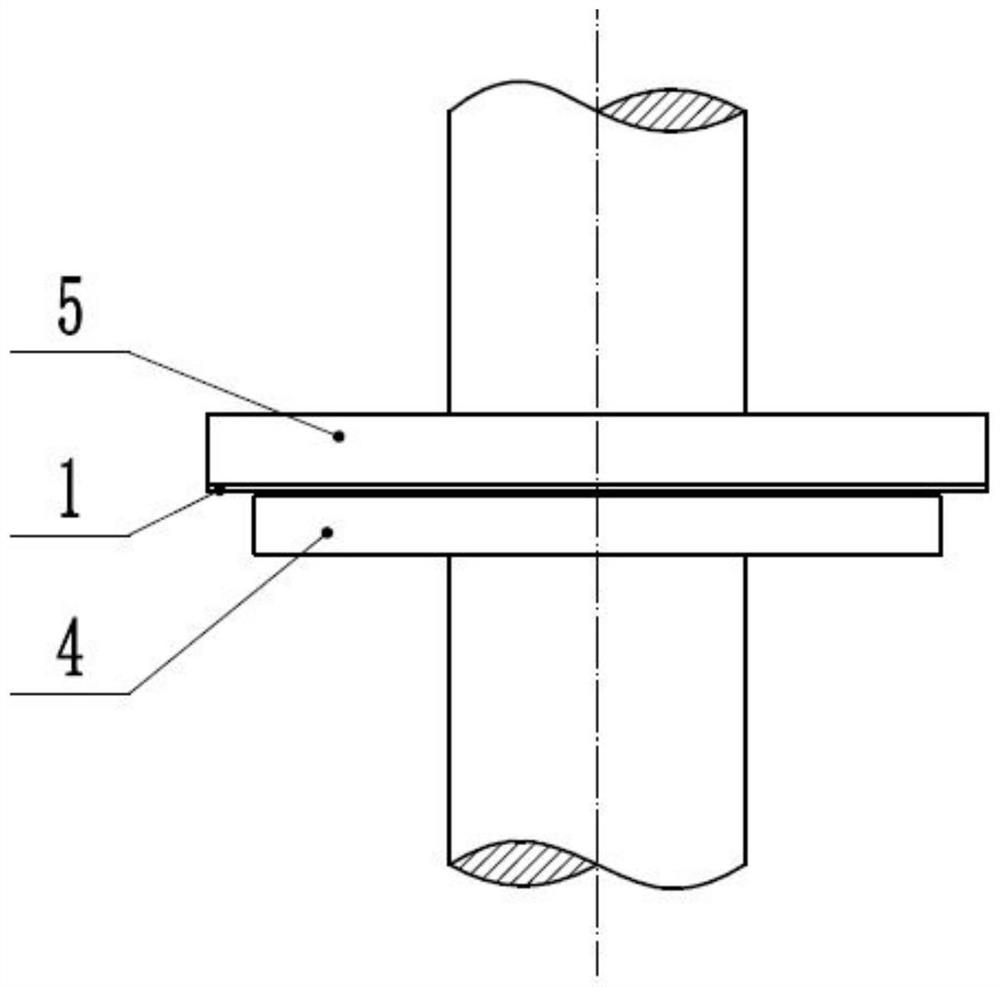

[0040] 2) Clean and dry the working surfaces of the specific-shaped flat metal foil (stepped first grade) 2, the specific shaped flat metal foil (stepped second grade) 3, and the thrust bearing housing 5 that needs to be provided with micro-grooved working surfaces Wait for preprocessing.

[0041] 3) Firstly lay the plan...

Embodiment 2

[0047] A method for manufacturing a patch type thrust pressurized gas bearing, comprising the following steps:

[0048] 1) Provide general metal foil. The size specification of the metal foil is selected to be compatible with the micro-groove specification and the bearing working surface specification. The metal foil is subjected to rapid material reduction processing as required to obtain part of the structure and micro-groove of the removed material. Special-shaped planar metal foil (spiral groove shape) 1 based on corresponding structure, see figure 1 (a).

[0049] 2) Clean and dry the working surface of the plane metal foil (spiral groove shape) 1 of a specific shape and the thrust bearing seat 5 that needs to be provided with a micro-groove working surface.

[0050] 3) Evenly lay and fix the plane metal foil (spiral groove shape) 1 of a specific shape on the working surface of the thrust bearing seat 5 according to the determined direction and position, and obtain the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com